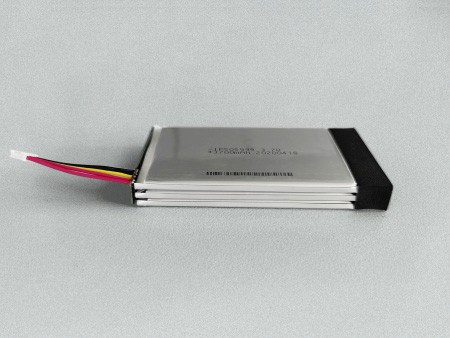

Flexible size, complete model

High energy density, good safety

Medical equipment, instruments, handheld equipment, special equipment, etc.

Charge temperature:-40℃ 0.2C

Discharge temperature:-50℃~+70℃

Polar scientific investigation, frigid zone emergency, special equipment, medical electronics, etc.

Intrinsic safety type/explosion-proof type

Meet Exia iiA/Exib iiB T1~T4 standard

Oil and gas drilling, mine locomotive, petrochemical industry, refuge grotto, etc.

Discharge rate 3C~100C

high discharge platform, long cycle life

UAV, model airplane, remote control model,

power tools, etc.

Thickness≤3mm, Minimum thickness is 0.4mm.

High energy density, long cycle life

Internet of Things, smart card, electronic tag,

bank card, wine label, cold chain, etc.

Special shape can be customize.

Arc, triangle, half-moon, circle, polygon, etc.

Small medical devices, wearable devices,

trackers, Internet of Things, etc.

| Model | Dimension | Nominal Capacity(mAh) | Impedance(mΩ) | Nominal Voltage(V) | ||

| Thickness(±0.3mm) | Width(±0.3mm) | Height(±0.5mm) | ||||

| 3578131 | 3.5 | 78 | 131 | 4000 | <40 | 3.7 |

| 3463110 | 3.4 | 63 | 110 | 2700 | <40 | 3.7 |

| 3845120 | 3.8 | 45 | 120 | 2200 | <40 | 3.7 |

| 366090 | 3.6 | 60 | 90 | 2000 | <40 | 3.7 | 3435165 | 3.4 | 35 | 165 | 1800 | <40 | 3.7 | 2453135 | 2.4 | 53 | 132 | 1400 | <40 | 3.7 | 385085 | 3.8 | 50 | 85 | 1300 | <60 | 3.7 | 344461 | 3.4 | 44 | 61 | 1200 | <60 | 3.7 | 255480 | 2.5 | 52 | 80 | 1150 | <50 | 3.7 |

| 393278 | 3.9 | 32 | 78 | 1100 | <65 | 3.7 |

| 305060 | 3 | 50 | 60 | 900 | <40 | 3.7 |

| 383450 | 3.8 | 34 | 50 | 600 | <70 | 3.7 |

| 383450 | 3.8 | 34 | 50 | 450 | <80 | 3.7 |

| 233759 | 2.4 | 37 | 59 | 380 | <80 | 3.7 |

| 392339 | 3.9 | 23 | 39 | 330 | <80 | 3.7 |

| 302441 | 2.8 | 24 | 40.5 | 250 | <100 | 3.7 |

| 251776 | 2.5 | 17 | 76 | 230 | <120 | 3.7 |

| 302145 | 3 | 21 | 45 | 210 | <150 | 3.7 |

| 222530 | 2.5 | 25 | 30 | 120 | <180 | 3.7 |

| 321239 | 3.1 | 12 | 39 | 100 | <200 | 3.7 |

Use the same winding process as the production of liquid lithium ion battery, wind up the positive electrode, negative electrode and electrolyte film, and package it with aluminum foil.

Cut the anode and cathode into a certain size, make them with electrolyte film by hot-pressing technology, and then package with aluminum foil.

Due to the polymer materials,

the cell will not catch fire or explode.

With the capacity of 6V400mAh,

its thickness can be as thin as 0.5mm.

40% lighter than the steel case

lithium ion battery with the same

capacity specification, and 20%

lighter than the aluminum case battery.

Due to the polymer materials,

the cell will not catch fire or explode.

With the capacity of 6V400mAh,

its thickness can be as thin as 0.5mm.

40% lighter than the steel case

lithium ion battery with the same

capacity specification, and 20%

lighter than the aluminum case battery.

The capacity of a lithium polymer battery depends on the thickness, width and length. It also depends on the material and size.

Fast estimation of polymer battery capacity, commonly used estimation formula (estimation only):

Capacity = Thickness * Width * Length *K (The unit of K is mah/mm^3)

Internal impedance refers to the impedance encountered by the current flowing through the lithium ion battery when the lithium ion battery is working. It is mainly composed of electrode materials, electrolyte, separator impedance and the contact impedance of each part, which are affected by the size, structure and assembly of the battery.

Charge Rate = Charge Current/Rated Capacity

The maximum charging rate is the safest, but it is not the best charging rate. A lower charging rate can better extend the service life of the battery.

Discharge Rate=Discharge Current/Rated Capacity

Discharge rate maintains safe discharge speed of the battery. In the specified time, the battery releases its rated capacity current, which is equal to the battery rated capacity multiple. Discharge rate is expressed by letter C.

| Lithium Polymer Battery | Lithium Ion Battery | |

| Raw Material | The anode, cathode or electrolyte uses polymer materials. |

Activated carbon, graphite, and organic electrolytes |

| Shape | Electrolytes are solid and colloidal and can vary in shape. |

Liquid electrolyte; Case packaging; The shape is not easy to change. |

| Safety | The polymer has high safety and is not easy to explode and burn. |

Lithium polymer battery is safer than lithium ion battery. |

| Raw Material | High voltage can be achieved by using polymer material multilayer combination to achieve high voltage. |

The nominal capacity of the lithium ion battery cell is 3.6V. For high voltage, lithium ion battery cells need to be connected in series |

| Capacity | The capacity of lithium polymer battery cell does not improve effectively. |

Lithium ion battery has a slightly higher capacity than that of lithium polymer battery. |

| Electrical Conductivity | Lithium polymer battery has low ionic conductivity of solid electrolyte. |

Lithium ion battery has stable electrical conductivity and is not affected by other materials. |

| Manufacture Technology | The thinner the lithium polymer battery, the better it can be manufactured. |

The thicker the lithium ion battery, the better it can be manufactured. |

| Price | Lithium polymer battery is generally more expensive than lithium ion battery. |

Lower price than that of lithium polymer battery |

The lithium polymer battery has a certain life. It doesn't mean that you can prolong battery life without using. Battery maintenance only has corresponding standards during using.

The process of assembling lithium polymer battery cells is called PACK, which connects single battery or multiple cells into lithium ion battery modules in series and parallel.

Lithium polymer battery pack consists of battery pack, bus bar, flexible connection, PCM, exterior package, output (including connector), highland barley paper, plastic holder and other auxiliary materials.

-40℃ Low Temperature Li-Polymer Battery Special Backup Instrument Nominal voltage:14.8V Nominal capacity:1700mAh Battery dimension:63*64.5*23.5(±0.2,mm)

3.6V 3200mAh Explosion-proof Lipo Battery Special Handheld Equipment Cell model: LA505357FB/1600mAh/3.6V Nominal voltage: 3.6V Nominal capacity: 3200mAh Application:oil station, gas station, mining, etc.

Connector is commonly known as plug-in unit, plug and sockets, etc. It is used to connect power supply and signal device. There are wire to wire connector and wire to board connector.

Lithium polymer batteries are considered to be a relatively environmentally friendly way of storing energy. However, if the discarded lithium polymer batteries are not recycled properly, they may cause environmental pollution.

| Category | Conventional Materials | Potential Environmental Pollution |

| Anode Material | LiCoO2/LiMn2O4/LiNiO2 | Heavy metal pollution; Co, Ni, Mn are strong carcinogens, toxic substances, and may change the environmental pH. |

| Electrolyte | LiPF6LiBF4/LiAsF6 | Change the environmental pH; Fluorine pollution |

| Volume (mAh/g) | 135~140 | 140~180 |

| Electrolyte Solvent | EC/PC/DC | It is difficult to degrade; Toxic; Burning will produce greenhouse gases. |

| Separator | PP/PE | Difficult to degrade |

| Adhesive | PVD/VDF/EPD | Fluorine pollution; Difficult to degrade |

When choosing lithium polymer batteries, we should search for well-known brands, so that the quality of batteries can be guaranteed. Although the price of many small brands in the market is cheap, the battery may have short life and poor quality.

Check if the capacity is clearly marked. A battery pack without a clearly marked capacity (such as 1000mAh or 1000 MAH) may be a poor quality battery pack or a recovered battery pack without quality assurance.

Without a PCM, the lithium polymer battery has the risk of deformation and leakage. In the competitive market, companies have sought cheaper PCM, or omitted them, leaving lithium polymer batteries explosive risk on the market.

Leave a message

Leave a message

We’ll get back to you soon