APR 10, 2020 Pageview:3471

Foreword: flaw detector is a portable industrial non-destructive flaw detector that can detect, locate, evaluate and diagnose various defects (weld joint, crack, inclusions, folds, pores, sand holes, etc.) in workpiece quickly, conveniently, without damage and accurately. It can apply to not only laboratory but also engineering field. It can be used in both laboratory and engineering field. The instrument can be widely used in manufacturing industry, steel and metallurgy industry, metal processing industry, chemical industry and other fields requiring flaw detection and quality control, and also widely used inspecial, railway transportation, boiler pressure vessel and other fields for in-service safety inspection and life assessment. Portable flaw detector has become the important tool of modern site test and provides efficient, portable, convenient and abundant backup power supply solution, which is the assurance of long-term site work for tester. Because of its advantages, 18650 lithium ion battery has been the preferred backup power supply of high-tech testing instrument.

Ⅰ. Design requirements

Backup lithium ion battery of flaw detector design requirements

Based on the features of flaw detector with high voltage and long working hour, the quality and stability of the device is very important, which requires that its power supply must have many single batteries with large capacity in parallel and series. During the operating process of flaw detector, a large amount of data need to be kept, so precise capacity display and alarm system notice users to keep the data in time to improve working efficiency. This backup power solution of flaw detector adopts intelligent chip. The host machine reads the capacity and relevant important data of intelligent chip by I2C communication mode and monitors the battery at every time so as to notice user for reasonable operation in time. Large Power integrated Sanyo battery has advantages of high specific energy, light weight, small size, long cycle life, good security, high voltage and nice consistency. Protection value is 12A, continuous working current is 7A, and capacity is 5000mAh, which fully meets the power requirement of device. The concrete design parameters are as follow:

1)Design requirement of the type of lithium ion battery: 18650-3S2P/5000mAh/11.1V

2)Design requirement of electric circuit:

Over-charged protection voltage of single battery: 4.35±0.25V

Over-charged recovery voltage of single battery: 4.15±0.50V

Over-discharged protection voltage of single battery: 2.40±0.08V

Over-discharged recovery voltage of single battery: 3.00±0.10V

Over-discharge cut-off current of battery pack (10ms): 30~35A

Over temperature protection value of battery pack (restorable): 70±5℃

The finished product has protective function of short circuit and reverse-charging.

3)Design requirement of cycle life: 300~500 times (national standard of charging and discharging)

4)Design requirement of housing dimension: refer to host machine housing

Ⅱ. Lithium ion battery design scheme of flaw detector:

1)Intelligent voltmeter protection board (PCM): it adopts SBS intelligent battery management system, uses advanced capacity calculation principle to accurately calculate the battery capacity, and reports the battery capacity information to the host machine through SMBUS. It also protects the functions of a rechargeable smart battery pack. Due to the chemical characteristics of lithium battery itself, overcharge, over-discharge, short circuit, overcurrent and over-temperature protection functions need to be provided to avoid causing combustion, explosion and other dangers.

2)18650 lithium ion battery/18650/2500mAh/3.7V Li-ion cell(SANYO)

3)Temperature switch: it is designed for temperature protection. When the battery is heated up to 70±5℃ due to any issues, the temperature switch begins to protect the battery.

4)MOSFET: it works as the switch in protective circuit to make sure that the voltages of two ends won’t be up and down, so that the voltage will be stable.

5)The capsulation of battery pack (housing)

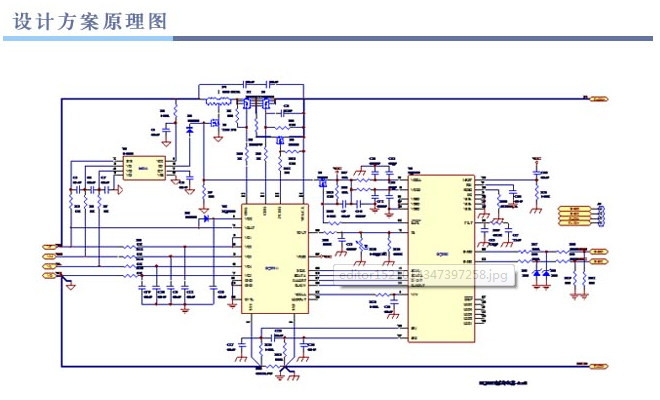

Design schematic diagram:

Product pictures

Leave a message

Leave a message

We’ll get back to you soon