Special Cell Manufacturing Center

special customization

Multiple Categories

As for material system, we now have ternary, lithium cobalt oxides, lithium iron, composite, and other multivariate system mature products. As for performance, product category covers low temperature charge and discharge battery and low temperature high rate batteries, high and low temperature special batteries, explosion-proof and coal safety performance of high safety battery, low temperature high energy density battery, etc.

Multiple Models

In terms of shape and structure, our products cover cylinder 18650, cylinder 26650, square aluminum shell 2270160 and various types of soft package polymer models. As for process design, we have high rate laminated process models and conventional winding process models.

Multiple Batches

In terms of product order batches, we can undertake battery tasks of various gradient quantities, ranging from the total amount of 600Ah to the large amount of 5000Ah and above, covering a wide range of batches.

High Quality Special Customization

The products can be developed, designed and verified according to customers' unique performance requirements to achieve special customization. High quality is mainly reflected in: We have strict quality control procedures and methods for both R&D sample preparation and production. We have data recording and full inspection process from pole piece to battery finished product, which can trace battery capacity and self-discharge data, etc.

Special Cell Manufacturing Center has

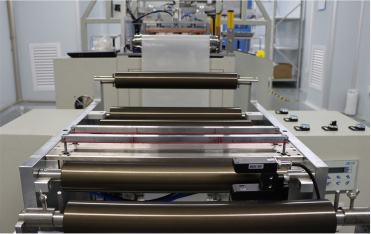

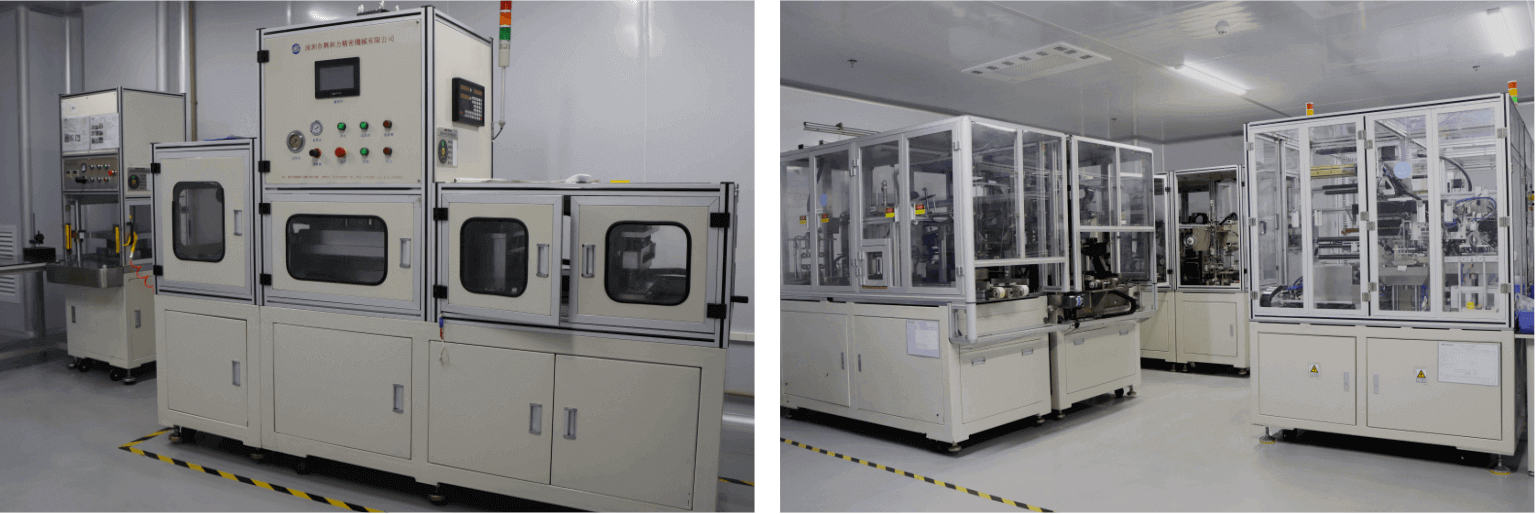

Special Cylinder Production Line, Special Polymer Winding Production Line, Special Laminating Production Line

Ten thousand grade purification, high standard temperature and humidity workshop

Special Battery Manufacturing Center

Provide high-quality customized PACK to fully meet the personalized and diversified needs of users

Actual production:1.5G Wh

Multiple Varieties

Products are widely used in medical, special, ship, exploration and mapping, security monitoring, power tools and other industries and fields; Product process, performance, size and assembly methods are diversified to meet the actual needs of industry customers.

Multiple Batches

The manufacturing center undertakes business from sample orders to ultra-small orders, small batch orders and batch production orders. According to the urgency of customers' use, we adopt the rolling planning mode to cooperate with customers to deliver in batches and produce on demand to meet customers' needs. There are various manufacturing and production modes, including lean unit production, assembly line production, pull production, one-flow production, rapid mold change and other lean production modes. The implementation of assembly line + assembly station operation mode perfectly implements multiple batches of multiple types of product frequent switching and on-schedule delivery.

Quick Response

Include multi-function work, rolling production plan, unit group operation, quick mold change, multi-line mobile adjustment, flexible split combination. In order to meet customer needs, all staff always waiting for the orders, to ensure quality and quantity, to meet customer needs as the first priority.

High Quality Customization

Full traceability system, automatic/semi-automatic operation, key positions are designated and make sure the responsibility of personnel, including the product process self-inspection, mutual inspection, special inspection, full inspection before shipment, QE sampling. Key components need to use high-precision detection equipment to carry out automatic detection or professional equipment detection. Production site standardized management, professional technology, quality assurance personnel on-site guidance, inspection, production intelligent detection, production equipment and testing equipment calibration need to follow "don't pass if the reason is not clear, don't pass if the responsibility is unknown, don't pass if there is no improvement measures " of "three-no pass" principle, so as to create super safe and reliable high-quality products production levels.

-

Senior CustomizationFocus on special lithium module

Senior CustomizationFocus on special lithium module

customization for 20 years

A total of 100 million sets of lithium -

Agile CustomizationFlexible manufacturing systems

Agile CustomizationFlexible manufacturing systems -

High Quality CustomizationGroup distribution system under zero-electric condition, Full traceability system

High Quality CustomizationGroup distribution system under zero-electric condition, Full traceability system