The detection and monitoring of power battery thermal runaway

Jun 04, 2019 Pageview:729

This is a very real problem, if the future of electric vehicles, the accidents (collision, bubble water), how to effectively monitor and detect? Personal ideas, is through a dedicated circuit block, about such a design prototype:

1) has the multiplex power input, can be in 12 v battery work and battery doesn't work to hang outside into the 12 v configuration possibilities.

Note: this is similar48 v battery function of exhaustion forced charge design considerations.

2) The working current is small enough to maintain a suitable work interval, through low power low threshold risk early warning and high power sensitivity threshold of sensing device.

3) Can form a low-power ASIC, then modular access to BMS and be a part of it.

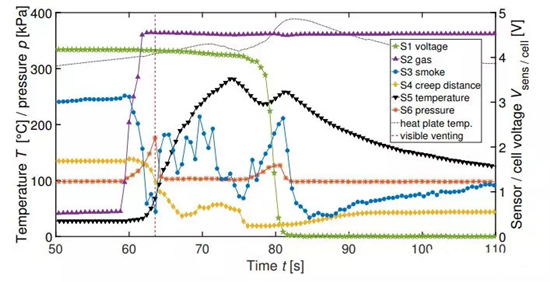

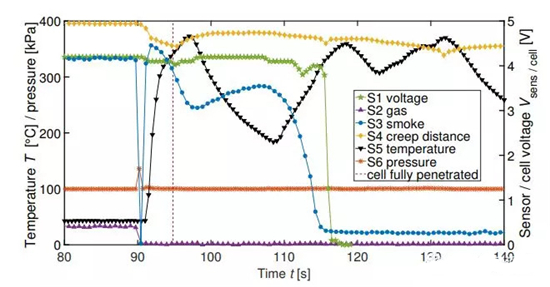

Deutsche ACCUMOTIVE a "Fast Thermal Runaway Detection for Lithium - Ion Cells in Large Scale Traction Batteries" there are still a lot of interesting content, the content of the extracted down can be do next device testing in the direction of perception.

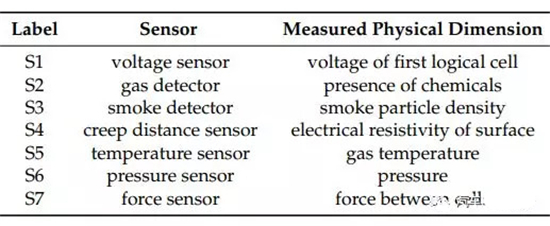

Here to choose a set of sensors.

Sensors S1, reusable modules within the monomer voltage sampling signal

Sensor S2 is adopted by the tin dioxide gas sensor made of (SnO2), its methane (CH4), propane (C3H8) or carbon monoxide (CO) of these cells in the process of thermal runaway exhaust gases.

S3 sensor is a kind of smoke detectors, which is based on infrared led original principle is through the photoelectric smoke detectors, consider the batteries in the process of thermal runaway smoke and other gases will cause the threshold change of sensor.

Sensor S4 here more clever idea using a two bonding pad on the PCB design, according to the inside of the surface cleanliness to assess the environmental changes. The output characteristic is according to the change of impedance to consider.

Sensor S5: using a high precision (NiCr - Ni) K type thermocouple measuring the temperature of the air and exhaust system.

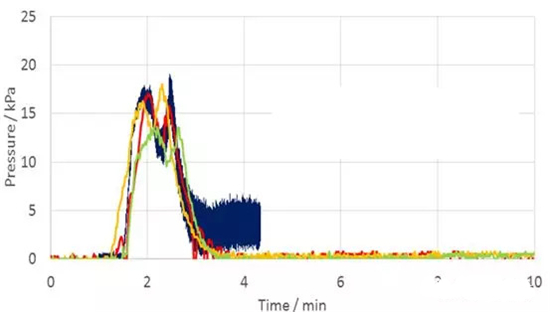

Sensor S6: measure the absolute pressure within 20 kpa psens or less acuities were 304 kpa pressure sensor, the principle of which is almost all companies are detected monomer thermal runaway in pressure can cause the battery system in the process of ascension

Sensor S7: film piezoresistive pressure sensors, the range of 0 n Fsens 445 n or less or less, within the module configuration, used for measuring the thermal runaway of the batteries and expansive force between the adjacent batteries.

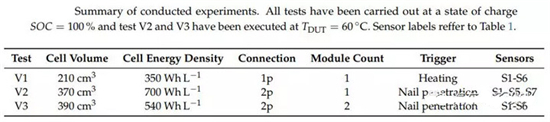

Configuration experiments: the process of the test condition is to use the batteries, 1 p and 2 p 100% SOC and 60 ° of environment temperature, under ind4 update behind different SOC and type of configuration, batteries for the thermal runaway of the summary of different test data. Here is based on the actual module configuration to test more reasonable

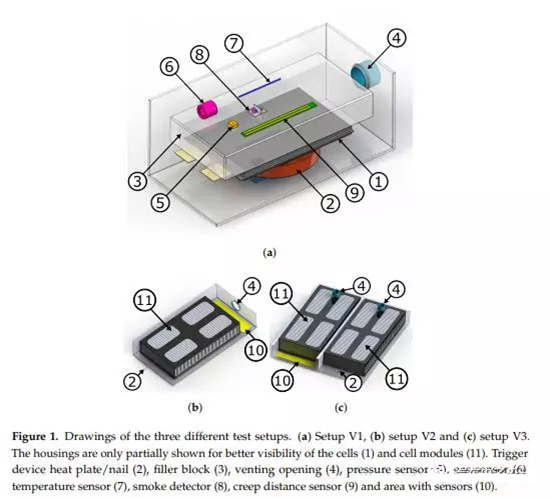

Test building: Experimental results of the data:

Experimental results of the data:

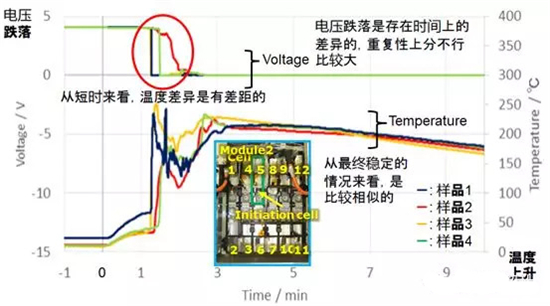

Sample 1

Sample 2

Sample 3

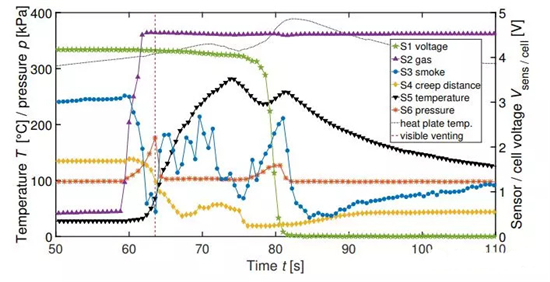

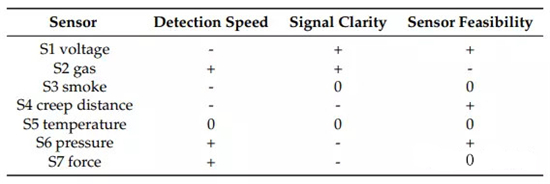

Test results, here listed the three basic items:

A) Detection speed: how fast detect thermal runaway.

B) Signal definition: definition of the sensor signal, considering signal-to-noise ratio in a real environment.

C) Sensor and practical feasibility: how easy the sensor deployment in the battery system.

This is evaluation result:

(S2) The reaction of velocity, gas sensor, pressure sensor (S6) and module (S7) fastest response

From the signal definition: voltage (S1), gas sensor (S2) can be; Pass to S3 and S5 is big more differentiation.

Integrated view: S1, S4, and S6 is feasible.

Note: the article written yesterday about JRC is similar, voltage drop in a long time scale is the spectrum of the signal, and the whole package of the two pressure sensors does become the direction of people's work

Summary: before you spent a lot of time to go to the gas sensor, gas sensor actually used in the application of the above problems, there's still a lot of life and easily influenced by other similar liquid leakage and glue volatile gases such as the flood, now want to consider a set of core sampling frequency, to build an independent MCU core to build the system, need to see how much time to maintain, in the field of sensor optimal allocation and the development of the algorithm is of great articles to do.

The page contains the contents of the machine translation.

- Prev Article: BYD's battery business is going independent.

- Next Article: Introduction of super lithium battery

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News