Application of graphene materials in the negative electrode of lithium battery

Jul 01, 2019 Pageview:906

[Introduction]

Lithium batteries are widely used in today's human society, such as electric vehicles and portable electronic devices. However, these commercial lithium batteries have low energy densities and cannot fully meet the needs of everyday use. Moreover, most of the batteries have a reduced capacity during rapid charge and discharge, and their rate characteristics are poor.

In addition, in addition to energy density and fast charge, the performance of long cycle life at high temperatures (around 60 degrees Celsius) is also important. Up to now, the nickel-rich and lithium-rich layered oxide materials that are considered to replace LiCoO2 have negligible energy density and cycle life loss during fast charging. Therefore, it is very important to find an advanced anode material for fast charging, because today's graphite anodes have lithium metal deposition to produce lithium dendrites during high-rate charging.

[Introduction]

Recently, the team of Dr. InHyukSon from Samsung Advanced Technology Research Institute of Korea and the team of Professor Jang WookChoi from Seoul National University (co-communication author) jointly published the article entitled "Grapheneballsforlithiumrechargeablebatterieswithfastchargingandhighvolumetricenergydensities" in the famous journal NatureCommunications. This article reports a graphene-SiOx assembled graphene sphere as a coating material for high-capacity nickel-rich layered cathode materials and lithium battery anode materials. Each graphene sphere consists of a SiOx nanoparticle located at the center and a graphene layer at the outer layer, similar to a 3D popcorn-like structure. SiOx nanoparticles have multiple effects, such as avoiding the formation of SiC layer at the SiOx-graphene interface during graphene growth, ensuring that the graphene spheres are uniformly coated on the cathode material, ensuring high specific capacity for the anode material. . Uniform coating of graphene balls on the nickel-rich positive electrode material enhances the stability of the electrolyte and electrode interface, and improves the fast charge performance and cycle stability of the positive electrode. A full cell made of a graphene-coated positive electrode and a graphene ball negative electrode has a high volume energy density of 800 WhL-1 under commercial battery conditions, and has a capacity retention rate of 78.6% after 500 cycles at 60 °C.

[Graphic introduction]

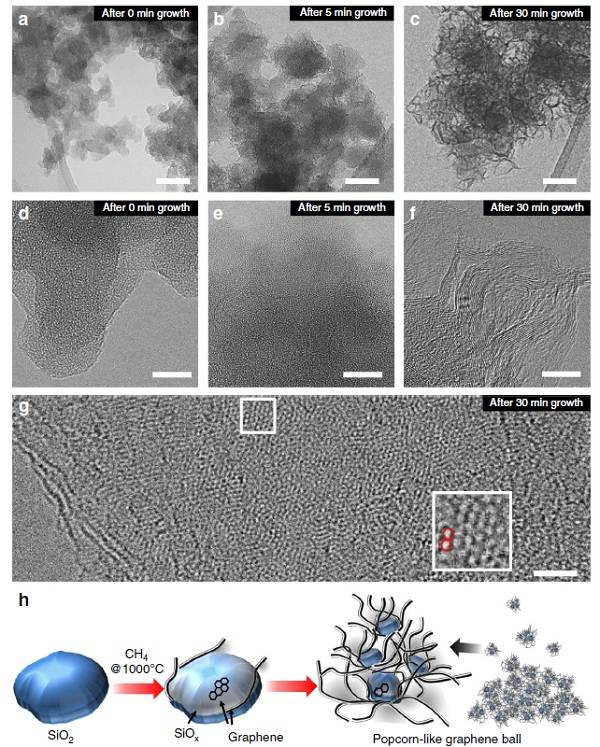

Figure 1: Growth of graphene by SiO2 nanoparticles.

a) TEM before CVD growth;

CVD growth b) TEM after 5 min after c) 30 min;

d)-f): a)-c) corresponding enlarged view in the figure;

g) Graphene grown in 30 min and an enlarged view of atomic energy levels;

h) Schematic diagram of the growth of popcorn graphene.

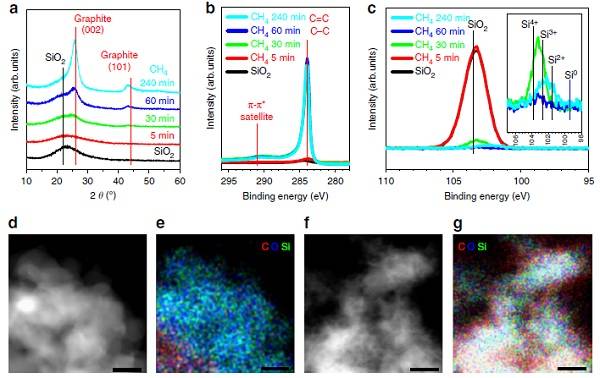

Figure 2: Analysis of graphene spheres during growth.

Characterization of the use of graphene growth during CVD growth:

a) XRD; b) XPS;

c) Si2p peak in XPS; EDX pattern of C, O, Si after graphene d)-e) 5 min and f)-g) 30 min on SiO2.

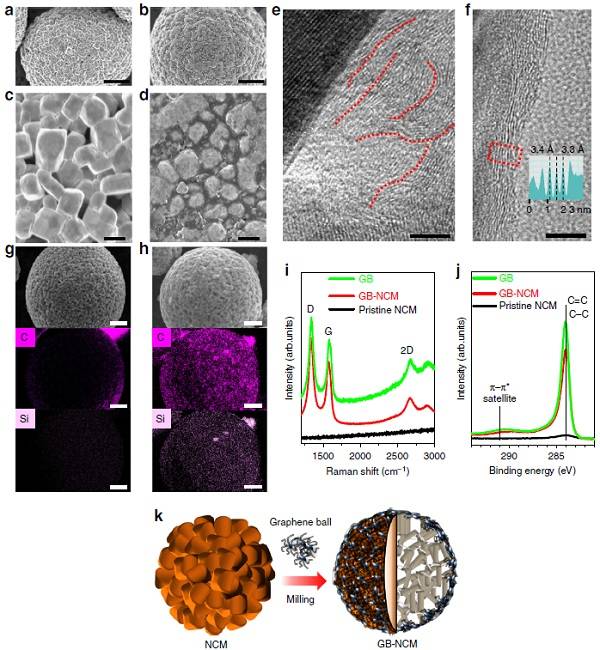

Figure 3: Graphene spheres coated with LiNi0.6Co0.1Mn0.3O2.

a)-c) SiO2 nanospheres before growth of graphene;

b)-d) a graphene sphere after coating the graphene;

Graphene sheet e) TEM image before and after f) coating;

i) A Raman diagram of graphene spheres;

j) XPS plot of the C1s peak of the three samples;

k) Schematic diagram of graphene spheres coated on LiNi6Co0.1Mn0.3O2.

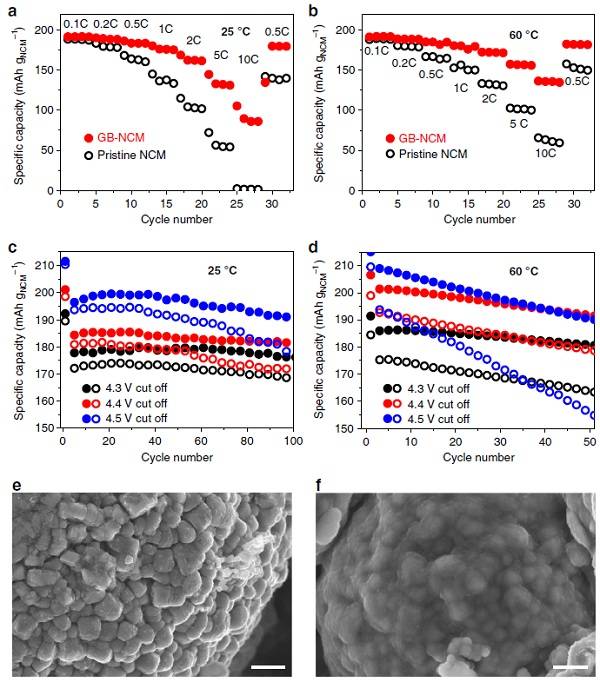

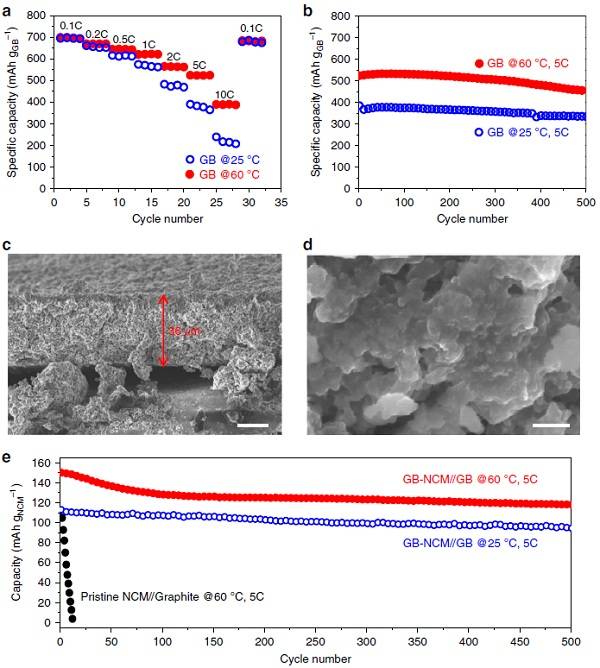

Figure 4: Performance characterization of fast charge and discharge and cycling.

2.5-4.3V voltage range a) 25 ° C and b) 60 ° C magnification characteristics:

Cycle performance maps of c) 25 ° C and d) 60 ° C at different cut-off voltages;

e) 100% cycle of graphene sphere coated NCM initially loaded with NCM and 60 ° C 4.3V cutoff voltage;

a) Half-cell rate characteristics of the graphene ball negative electrode at 25/60 ° C;

b) Long cycle performance diagram of graphene ball negative electrode at 5C current density 25/50 ° C;

5C current density cycle 500 times of graphene ball negative electrode c) SEM sectional view and its d) enlarged view:

e) Graphene sphere-NCM/graphene ball full cell long cycle characteristics at 25/60 °C at 5C.

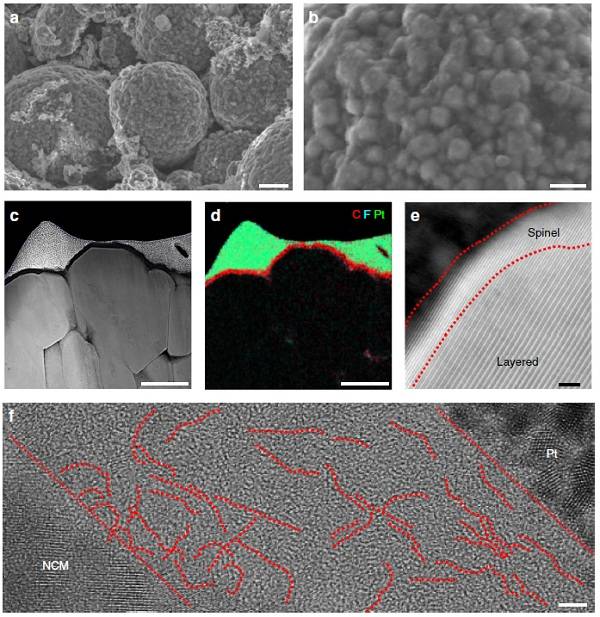

Figure 6: Characterization of full cell performance after 500 cycles at 60 °C.

a) -b) graphene sphere-NCM low/high magnification SEM image;

c) A STEM image of the section;

d) EDX diagram of the three elements C, F and Pt in Figure c;

e) A high power STEM image of the graphene sphere-NCM surface;

f) TEM image of the NCM surface.

[Summary]

A graphene-silica composite, a graphene sphere, was prepared by a CVD method. The layered three-dimensional structure allows graphene to grow between the silicon oxide particles, and 1 wt% of graphene spheres are uniformly coated in the nickel-rich layered cathode material by Nobilta ball milling technique. Cycle life and fast charge performance are improved by suppressing adverse side reactions and improving conductivity. The graphene sphere is used for the specific capacity of the anode to reach 716.2mAg-1. Compared with the battery without the graphene sphere, the volumetric energy density of the whole battery is increased by 27.6% under the conditions of commercial preparation, reaching 800WhL-1, 5C rate. The capacity of the capacitor for 500 cycles at 60 ° C is still 78.6%.

The page contains the contents of the machine translation.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News