How do you maximize the power of a long-life battery?

Sep 16, 2019 Pageview:1127

The battery life is the development of wireless sensor nodes is an important consideration, it will constitute the Internet of things (IIoT).In many applications, sensor nodes need to install in inaccessible location, not to mention the service.Sensor nodes in energy needs is free, because its cost is too high, it is difficult to give them power, or to make maintenance personnel change the battery on a regular basis.

In addition to the electronic products are processed in a low power consumption, battery itself also needs to be able to support a very long time, may be up to 20 years.Many battery chemistry does not support such a long service life, even in support of special low energy electron products because of their self-discharge rate.

Lithium sulfuryl chloride chemistry, however, can have very low self-discharge rate.Therefore, chemistry provides by far the longest life and can see the highest energy autonomy, it is suitable for iot sensor nodes, and other small size important equipment.In recent 40 years, the service life of lithium sulfuryl chloride compounds was confirmed.Aa size batteries in practical instrument on the service life of more than 20 years.

However, as the long life battery power supply system of the expansion of application scope, consider lithium sulfuryl chloride features is very important.Wireless communication to the sensor nodes are added and executive function, such as gas or liquid valve opening and closing capacity, increase the peak current for the batteries.

A typical sensor node or metering applications in micro controller will be dormant in most of the time, it will read the data in the normal time intervals, store them in the local memory.Within a short time interval, the controller will activate the wireless communication module, and to the gateway or the server sends data packets.Wireless interface transmission, the current is 500 ma;But it only need a few hundred milliseconds.

Despite the power of the battery seems to support the short-term peak current, and the effects of aging is inevitable can reduce in the field of life.Battery capacity is not only influenced by self-discharge rate, but also by producing a large amount of electric current pulse impedance increases.

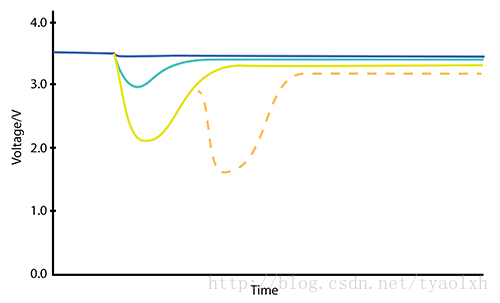

The influence of different sizes of electric current pulse image.

Figure 1: the influence of different size of current pulse on voltage with time, showing continuous pulse potential cumulative effect.Using the constant low current will restore voltage level.

Lithium sulfuryl chloride battery chemistry self-discharge rate is very low, largely due to lithium ion in anode surface discharge formed when a passivation layer.The insulation layer limits the flow of electric current, but by placing the load on the battery, can fall off part.However, due to form a pathway through the passivation layer for chemical process, there is delay.This is a sign of transient voltage drop, and then slowly rising is under constant load voltage.

Transient voltage drop depends on the passivation layer thickness and density.The higher the discharge current, provided by the lower voltage.In the case of partial discharge, remove load tend to increase the amount of passivation, increase the voltage to reduce and delay.

If the d size batteries, such as Tadirantl - 5134 / P, gradually release the continuous load of about 50 mu A, it will continue to provide current close to the rated voltage in A period of more than ten years.However, if you need any batteries provide greater current pulse, is going to change.By using the same D - size cells and use it to transfer the current 150 ma, pulse, Tadiran experiments show that the same cells in about 2 years time will remain 3 volts.Began to decline, voltage, after 5 years gradually decreased to 1.5 V.In circuit design, the expected voltage higher than 1.5 V, seemed completely discharge the battery in five years, not 10 or 20.Batteries, however, still have enough storage charge, if the system is able to use it, also can continue to provide the energy for the 10 years.

Sulfuryl chloride using lithium battery to extend the service life is the key to eliminate the current demand, so as not to produce large current pulse.The need to use a pulse energy buffer device to provide energy, battery to provide a constant flow of charge into the buffer circuit.

To provide a method of controlled energy buffer is using a large capacitor and dc/dc converters, such as Texas instruments TPS62740 to adjust the charge into the condenser.In order to ensure enough charge to run a wireless link hundreds of microseconds, double layer capacitor or the super capacitor provides a suitable choice.

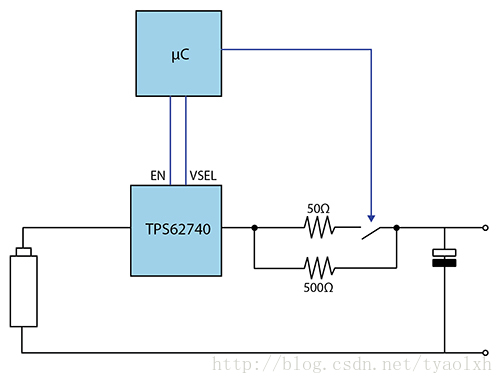

Use of Texas instruments TPS62740 micro controller.

Figure 2: using single-chip microcomputer control with TPS62740 to super capacitor voltage of power supply.

Circuit design using dc/dc converter output resistor to limit current into the super capacitor, at the same time, the current extracted from high capacity of the original cells, such as found in TadiranXTRA series.Need to choose a resistor to keep the current demand in accordance with long service life.Although can through the resistor will be the main battery is connected to the capacitor, but using a DC/DC converter has the advantage that it can dynamically adjust the output voltage, to reduce the energy loss of the resistor as far as possible.

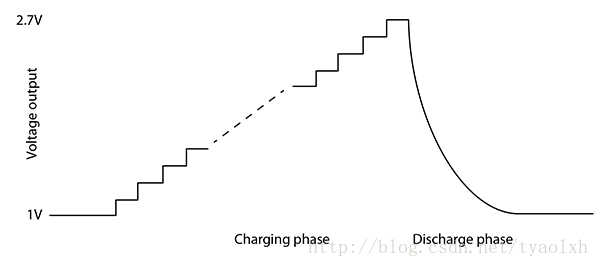

A programmable DC/DC converters, such as TPS62740 can, as a super capacitor charging capacity, increase its output voltage increment.A summary of a proposal is an increase of 100 mv every 30 or 60 seconds.The total charging time may be in more than 10 minutes.During this period, however, due to the supply voltage is gradually increased, reduced resistance will always be less than 100 mv.Though the battery demand will rise sharply, but every increase the voltage, electric current requirement is two to four ma ma, it won't cause too much adverse effect to the internal resistance.

Dc/dc converter power supply voltage range will be limited to two factors: micro controller need provided by the downstream of the capacitor voltage and maximum voltage of super capacitor, usually in the range of 2.5 V to 2.7 V.Embedded microcontroller might expect voltage range from 1 to 2 volts.Therefore, DC/DC converter will be expected from 1 V to 2.7 V within the scope of operation, it can depend on single chip microcomputer and the selection of the super capacitor.

At startup, super capacitor need to be charging to the desired voltage level by the microcontroller.At this stage, a large resistance can be used to properly limit current into the super capacitor.Once reach the goal of initial voltage, it can be a smaller resistor is converted to a minimum loss.This can be achieved by the two resistor connected in parallel.Usually consists of single-chip computer operating switch can ensure use higher resistance paths in the start-up process.After achieve voltage level, micro controller to switch in low resistance path.

Because of the DC/DC converter switch and current limiting resistor conversion caused some damage;However, the operation of the cascade can help maintain overall efficiency is close to 90%.The result of the power control strategy is to maximize the lithium sulfuryl chloride battery life of the circuit.

In the process of charging, gradually increase the voltage figure.

Figure 3: in the process of charging, when radio module is active, in the process of charging, the step voltage phase in voltage.

The page contains the contents of the machine translation.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News