The basic structure of the square battery

Sep 19, 2019 Pageview:3361

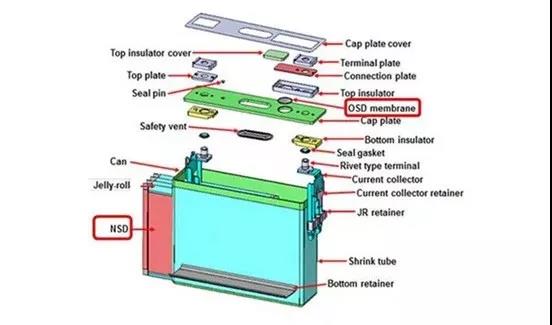

Square cell structure

A typical square lithium battery, the main components include: head, shell, positive plate and negative plate, diaphragm of laminated or winding, insulation, safety components, etc.Among them, two of the red circle is the security structure, NSD needle safety device;OSD overcharge protection device.

NailSafety device needle safety protection device (NSD).This is added on the outside of the core winding of the metal layer, such as copper plates.Acupuncture when it happens, in the needle position of local high current through a large area of copper sheet quickly lower the current per unit area, in order to prevent needle position and local overheating, ease battery thermal runaway.

Overcharge safety protection devices (OSD, Overcharge Safety Device), at present the safety design, could be seen in many cells.Generally is a sheet metal, used with the fuse, the fuse can design on the fluid to the anode sets, overcharge the battery internal pressure makes the OSD trigger internal short circuit, instantaneous large current, which makes the fuse fusing, to cut off the circuit inside the battery current.

Square cell structure General for the steel or aluminum shell, shell as the pursuit of the energy density of the market drivers and the progress of production process, aluminum shell gradually become the mainstream.

General for the steel or aluminum shell, shell as the pursuit of the energy density of the market drivers and the progress of production process, aluminum shell gradually become the mainstream.

Square battery characteristics

Advantages, square battery encapsulation high reliability;The system energy efficiency;Relatively light weight, high energy density;Expansion and structure is relatively simple, relatively convenient, is the current capacity by increasing monomer to improve the energy density of important option;Single capacity is big, the system structure is relatively simple, making it possible to by monitoring of monomer;Another advantage of system simple stability is relatively good.

Drawback, the square lithium batteries can be customized according to the size of the product production, so there are thousands of models on the market, and because the model is too much, process is very difficult to unity;Production automation level is not high, the individual difference is bigger, in large-scale applications, the system of life is far lower than the single life problems.

Here, have to mention issued in July 2017, formally in February on the implementation of national recommended standard "(GB/T34013-2017 electric cars with size of power battery products, including for square battery, given the size of the eight series, and the following table is shown in the diagram below.

Square lithium-ion batteries, capacity enlarged the characteristics of face how to change?

Square lithium-ion batteries, capacity enlarged the characteristics of face how to change?

Personal think, lead to cell size, the effect of the short term may not be particularly evident, even some people think this time give guidance, will tie industry development, and change the product size, for cell production, is not just a matter of fixtures, great influence.But as a recommendation, as long as you can to make preparations for the new production capacity and production line adjustment of manufacturer is a tendency, in the long run, necessary to develop in the direction of a series of specifications size gradually have a role in promoting.The batteries and the consistency of the module is the premise of a real pilot use.As for the technical route across may arise in the future, it doesn't really affect did not appear before crossing to the visible efforts to goals.

The main manufacturers

Just see two form in "China" battery, major domestic manufacturers information here.

Square lithium-ion batteries, capacity enlarged the characteristics of face how to change?

Square lithium-ion batteries, capacity enlarged the characteristics of face how to change?

Data sources:Power batteryApplied branch of research

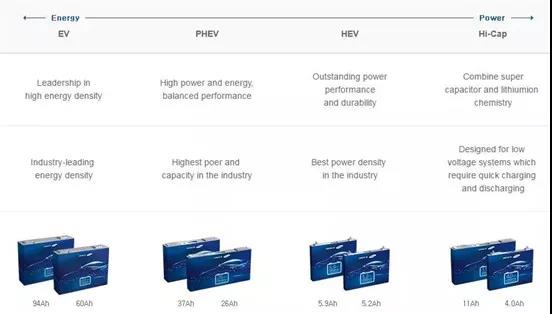

Abroad the main manufacturer Samsung SDI, the anode materials mainly adopts the NCA and sliding, square aluminum shell.The BMW i3 famous cases.Samsung's website shows square battery monomer.Products include high-energy BEV (electric) 60 ah, 94 ah battery;PHEV (plug-in hybrid electric vehicle) 26 ah, 37 ah battery (26 ah will gradually be replaced by 37 ah);HEV (hybrid electric vehicle) 5.2 5.9 Ah Ah, the battery;High power battery (4.0 Ah, 11 Ah), a total of four series.

Square lithium-ion batteries, capacity enlarged the characteristics of face how to change? Typical square battery module

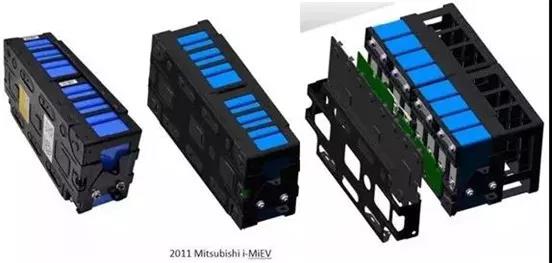

Typical square battery module

Below is the mitsubishi i-miev in 2011 battery module, PCB collection and cell voltage, temperature, through bolts on both ends.Between the cell is the most common way of busbar and bolt connection.

Square lithium-ion batteries, capacity enlarged the characteristics of face how to change?

Following is my 2012 Toyota prius PHEV battery module, using wire (now this way of wiring harness collection, feel is very troublesome in some situation, exist hidden danger) to gather the cell information, also USES the bolt connection, but increased the orange part, for their own protection.

Square lithium-ion batteries, capacity enlarged the characteristics of face how to change?

Here is my 2014 Volkswagen jetta HEV battery module, by the side of layering to tighten module, two end plate lateral plus insulation plastic cover plate.

Square lithium-ion batteries, capacity enlarged the characteristics of face how to change?

Square lithium-ion batteries, capacity enlarged the characteristics of face how to change?

Mass eGolf2015MY battery module, the design of the end plate of the function is rich, lose weight meets the requirements of structural strength at the same time, also reached the assembly requirements, using PCB acquisition cell information, only need to set aside on both ends of the module of low-pressure joint (now in this way more and more modules). Square lithium-ion batteries, capacity enlarged the characteristics of face how to change?

Square lithium-ion batteries, capacity enlarged the characteristics of face how to change?

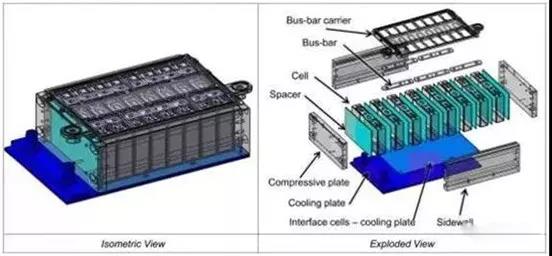

Below is one of the audi 2014 PHEV2 module design concept, matching the design of the surface plate, from the diagram you can see above to see some of the internal structure.

Square lithium-ion batteries, capacity enlarged the characteristics of face how to change?

The BMW i3, the use of Samsung SDI square batteries.Battery pack with a total of eight modules, each module has 12 batteries in series, a total of 96 batteries in series, 183 km range version USES 94 ah batteries, as shown in the figure below.(note, below is not now the latest version of the legend, the Internet video shows the latest version of the pack box body is different from previous version.)Aluminum soldering module shell, four corners have installed via fixed to the case pack, the structure is simple, is advantageous to the automated manufacturing.

Square lithium-ion batteries, capacity enlarged the characteristics of face how to change?

Square battery capacity big, relatively easier cylindrical batteries, in the process of ascension capacity, less restricted.But with the increase of monomer volume, also appeared some problems, such as ballooning serious side, cooling difficult and non-uniformity increased.

Square battery capacity big, relatively easier cylindrical batteries, in the process of ascension capacity, less restricted.But with the increase of monomer volume, also appeared some problems, such as ballooning serious side, cooling difficult and non-uniformity increased.

The page contains the contents of the machine translation.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News