Brief analysis of various anode materials of lithium battery

Aug 26, 2019 Pageview:1255

The lithium battery main anode materials are tin base material, lithium base material, lithium titanate, carbon nanotube and graphene materials. lithium battery energy density of the cathode material is one of the main factors influencing the lithium battery energy density, lithium battery cathode materials, anode materials, electrolytes, the diaphragm is known as the four core material of lithium-ion batteries. Here we make a brief introduction of all kinds of performance of the anode materials, the advantages and disadvantages, and possible improvement direction.

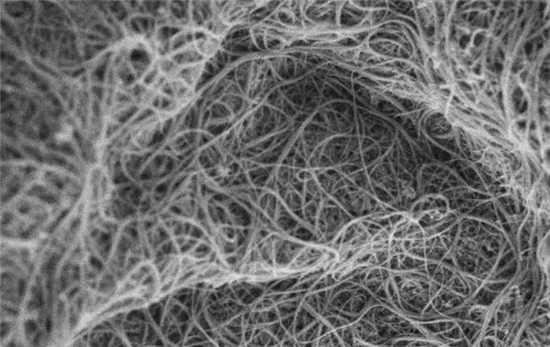

Carbon nanotubes

Carbon nanotubes is a kind of graphitization structure of carbon material, itself has excellent electric conductivity, at the same time because of its small when take off the intercalated-li depth, short trip, as the cathode material in the big ratio when charging and discharging the polarization effect is small, can improve the battery charge and discharge properties.

Directly, however, carbon nanotubes as a lithium battery cathode material, there are not reversible capacity is high, the voltage hysteresis and discharge platform is not obvious.Using simple filter such as Ng single-walled carbon nanotubes was prepared, its directly as the cathode material, its first discharge capacity is 1700 mah/g, the reversible capacity is 400 mah/g only.

Figure 1 carbon nanotube cathode materials

Another application of carbon nanotubes in the cathode is with other anode materials (graphite, lithium titanate, tin, silicon, etc.) composite, using its unique hollow structure, and the advantages of high conductivity and large specific surface area as a carrier to improve the performance of other anode materials.By chemical vapor deposition method, such as guo in expanded graphite holes in situ growth of carbon nanotubes, expanded graphite/carbon nanotube composite material was synthesized, the reversible capacity is 443 mah/g, for the first time in 1 c rate charging and discharging cycle after 50 times, the reversible capacity can reach 259 mah/g.The hollow structure of carbon nanotubes and expanded graphite holes, offers a wide range of lithium activity, and this structure can buffer material volume effect produced in the process of charging and discharging.

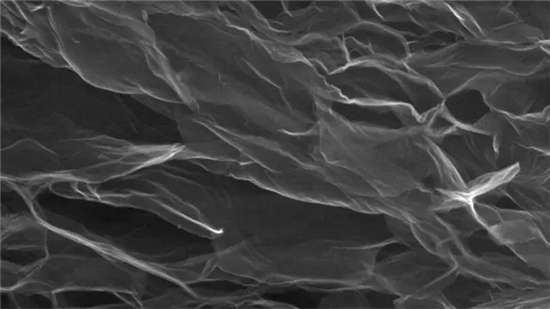

graphene

In 2004 the university of Manchester researchers found that graphene materials for the first time, and won a Nobel Prize.Graphene is a formed from carbon six-member ring of new carbon materials, has many excellent properties, such as large specific surface (about 2600 m2g - 1), high coefficient of thermal conductivity (about 5300 wm - 1 k - 1), high electron conductivity (electron mobility for 15000 s cm2v - 1-1) and good mechanical properties, referred to asLithium ion batteriesMaterials and has attracted much attention.

Graphene directly as a lithium battery cathode material, have very good electrochemical performance.Laboratory using hydrazine hydrate as reducing agent, the preparation of the jungle of graphene morphology and its character of both hard and soft carbon carbon and above 0.5 V voltage range, show the characteristics of the capacitor.

Figure 2 graphene anode materials

Graphene anode materials under 1 c discharge rate, the reversible capacity is 650 mah/g, for the first time after 100 times charging and discharging cycle capacity can reach 460 mah/g.Graphene also can be used as conductive agent, the anode materials and other composite, improve the electrochemical performance of anode materials.Such as zai-shallow pits by ultrasonic dispersion of Fe3O4 / graphene composites, prepared by the current of 200 ma/g density to devolve electricity, after 50 cycles, the capacity is 1235 mah/g;In the 5000 s and 10000 ma/g current density to devolve electricity, after a 700 - cycle capacity can reach 450 mah/g and 315 mah/g, showed a high capacity and good cycle performance.

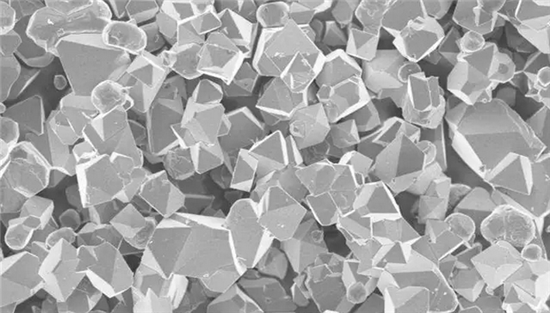

Lithium titanate

Spinel lithium titanate as an anode materials of concern, because has the following advantages:

1) before and after take off the intercalated-li lithium titanate almost "zero strain (to take off the intercalated-li crystal cell parameters before and after" a from 0.836 nm to only 0.837 nm).

2) the intercalated-li higher potential (1.55 V), avoid "lithium dendrite", high security;

3) has a flat voltage platform;

4) chemical diffusion coefficient and coulomb efficiency.

Many advantages of lithium titanate determines its excellent cycle performance and high security, however, its electrical conductivity is not high, large current charge and discharge capacity attenuation serious, usually adopt surface modification or doping to improve its conductivity.Such as shaw with Mg (NO3) 2 as the source of magnesium, prepared by solid phase method of magnesium 2 + doped lithium titanate, show that doping magnesium 2 + didn't destroy the spinel lithium titanate crystal structure, and doped material after a better dispersion, its specific capacity under the condition of 10 c discharge rate can reach 83.8 mAh/g, is 2.2 times of that of without doping, and no obvious attenuation after 10 times to charge and discharge cycle capacity, by alternating current impedance test show that the doped material after the charge transfer resistance is decreased obviously.Zheng through high temperature solid phase method, such as lithium Li2CO3 and citric acid were used respectively as a source of lithium, pure phase lithium titanate was prepared and the carbon coated lithium titanate.

Figure 3 lithium titanate cathode materials

Experiments show that the carbon coating of lithium titanate with smaller particle size and good dispersion, showed better electrochemical properties, mainly due to the carbon coating can improve the lithium titanate particles on the surface of the electronic conductivity, and smaller particle size reduces the Li + diffusion path.

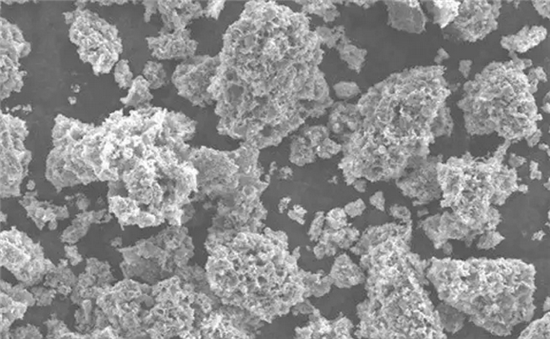

Silicon-based materials

Silicon as lithium ion battery anode materials ideal, has the following advantages:

1) silicon can form Li4.4 Si alloy with lithium, lithium storage theory given as high as 4200 mah/g (more than 10 times of graphite given);

2) silicon intercalated-li potential (0.5 V) is slightly higher than that of graphite, when the charging is difficult to form "lithium dendrite";

3) silicon and electrolyte low reactivity, organic solvents were embedded phenomenon will not occur.

Silicon, however, the electrode will happen in the process of charging and discharging cycle performance and capacity attenuation, there are mainly two reasons:

1) silicon and the generation of lithium Li4.4 Si alloy, volume expansion is as high as 320%, the huge volume change easily lead to fall out of the active materials, and thus reduce the electrical contact between, cause electrode cycle performance drops rapidly;

2) the LiPF6 electrolyte decomposition of trace HF etching silicon, caused the silicon electrode capacity attenuation.

In order to improve the electrochemical performance of silicon electrode, usually have the following way: the preparation of nanometer silicon materials, alloy materials and composite materials.Such as Ge, the chemical etching of the boron doped silicon nanowires, prepared by the charge and discharge electricity flow in the 2 a/g, circulation capacity after the 250 weeks still can be reached 2000 mah/g, showed excellent electrochemical performance, due to the lithium off silicon nanowires embedded mechanism can effectively alleviate the volume expansion in the process of circulation.Liu was prepared by high energy ball mill, such as the Si - NiSi - Ni complexes, then using HNO3 dissolved compounds of Ni elemental, the porous structure of Si - NiSi compounds.

Figure 4 silicon-based anode materials

Through XRD characterization, NiSi alloy system in existence, it has not only provided a reversible capacity as anode materials, also with particles inside the pore, buffer volume expansion in the process of silicon in charge and discharge cycle, improve the cycle performance of silicon electrode.Lee using phenolic resin as carbon source, such as in argon atmosphere at 700 ℃ high temperature pyrolysis, the preparation of core-shell type Si/C composite material, after 10 cycles of compound irreversible capacity is 1029 mah/g, still shows that Na2CO3 forming covalent bonds between the silicon surface with phenolic resin, and then high temperature cracking, can improve the contact between silicon and pyrolysis carbon, so as to improve the circulation of anode materials, reduce the irreversible capacity loss.

Tin alloy

SnCoC in tin alloy anode materials is more successful commercialization of materials, the Sn, Co and C three elements mixing at the atomic level, not crystallization processing and, the material can effectively inhibit the process of charging and discharging volume change of electrode material, improve the cycle life.In 2011, Japan's SONY announced by Sn series of amorphous material as a capacity of 3.5 18650 cylindrical battery cathode AH.Elemental tin theoretical specific capacity is 994 mah/g, can with other metal formation of intermetallic compounds such as Li, Si, Co.Such as Xue USES an electric plating first prepared the three-dimensional porous structure of Cu film carrier, and then by electrodeposition in Cu thin film carrier surface load of Sn - Co alloy, which was prepared by three-dimensional porous structure of Sn - Co alloy.

The material of the first discharge specific capacity of 636.3 mAh/g, coulomb efficiency reached 83.1%, for the first time after 70 times charging and discharging cycle specific capacity can still be reached 511.0 mAh/g.Wang, such as graphite as dispersant, SnO/the SiO and the mixture of metallic lithium as reactants, by using high energy mechanical ball mill and the post heat treatment, the preparation of the graphite evenly dispersed in the matrix of Sn/Si alloy, the material after 200 times charging and discharging cycle, the reversible capacity can reach 574.1 mAh/g, still is better than single SnO or the SiO anode materials.

Tin oxide

SnO2 because has high theoretical specific capacity (781 mah/g), much attention has been paid to the, however, there are some problems in its application process: first the irreversible capacity big, the intercalated-li when there is a big volume effect of volume expansion (250% ~ 300%), easy to reunite in the process of circulation, etc.

Research shows that, through the preparation of composite materials, can effectively restrain SnO2 particles together, at the same time also can alleviate the intercalated-li volume effect, improve the electrochemical stability of the SnO2.Zhou by chemical deposition and high temperature sintering, such as the preparation of SnO2 / graphite composite material, its under the current density of 100 ma/g, specific capacity can reach more than 450 mah/g, under the current density of 2400 ma/g, the reversible specific capacity of more than 230 mah/g, the experimental results show that the graphite as the carrier, not only can scatter SnO2 particles more evenly, and can effectively restrain particles together, improve the cycle stability of the material.

To sum up, in recent years, lithium ion battery cathode material in direction of high capacity, long cycle life and low cost.Metal (tin, silicon) material in high volume at the same time with the volume change, due to the capacity of the metal alloy material is proportional to the volume change, and the actual batteries do not allow the big changes in volume (usually less than 5%), so its capacity to play in the practical application is limited by the larger, solve or improve the effect of volume change will become the direction of research and development of metal base material.

Lithium titanate because has a small volume change, long cycle life, and good security and other significant advantages, in the field of electric vehicles and other large-scale energy storage has great potential, due to its low energy density, and high voltage anode material LiMn1.5 Ni0.5 matching use, m1 is high security in the futurePower batteryThe development direction.

Carbon nanomaterials (carbon nanotubes and graphene) with specific surface area, high electrical conductivity, chemical stability, etc, have potential applications in new lithium ion battery.Carbon nano materials as anode materials being alone, however, the high irreversible capacity, voltage hysteresis, anode materials and other composite use is the practical choice.

The page contains the contents of the machine translation.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News