Brief Analysis of Low Temperature Analysis of Lithium Ion Batteries in winter

Sep 30, 2019 Pageview:1545

The performance of lithium-ion batteries is greatly affected by the kinetic characteristics. Since Li+ needs to be desolvated first when it is embedded in graphite materials, it needs to consume a certain amount of energy, which hinders the diffusion of Li+ into the graphite. On the contrary, when Li+ is taken out of the graphite material and enters the solution, the solvation process first occurs, and the solvation process does not need to consume energy. Li+ can quickly remove the graphite, thus causing the graphite material to have a poor charge acceptance as that of discharge.

At low temperatures, the kinetics of the graphite negative electrode progresses poorly. Therefore, the electrochemical polarization of the negative electrode is obviously intensified during the charging process, which easily leads to the precipitation of metallic lithium on the surface of the negative electrode. ChristianvonLu at the Technical University of Munich, Germany Ders et al. showed that at -2 ° C, the charge rate exceeds C/2, which significantly increases the amount of metal lithium precipitated. For example, at C/2 rate, the amount of lithium on the surface of the negative electrode is about 5.5% of the entire charge capacity, but It will reach 9% at 1C rate. The precipitated metallic lithium may further develop and eventually become a lithium dendrite, which breaks through the separator and causes a short circuit between the positive and negative electrodes. Therefore, it is necessary to avoid charging the lithium ion battery at a low temperature. When the battery must be charged at a low temperature, it is necessary to select a small current to charge the lithium ion battery as much as possible, and to fully suspend the lithium ion battery after charging, thereby ensuring The lithium metal precipitated from the negative electrode can react with the graphite and re-embed into the inside of the graphite negative electrode.

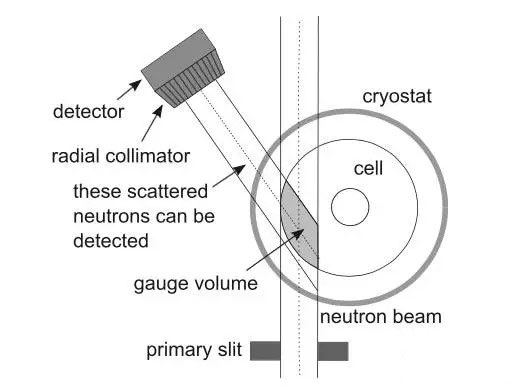

Veronika Zinth of the Technical University of Munich and others used neutron diffraction to study the lithium evolution behavior of lithium ion batteries at -20 °C. Neutron diffraction is a new detection method in recent years. Compared with XRD, neutron diffraction is more sensitive to light elements (Li, O, N, etc.), so it is very suitable for non-destructive testing of lithium-ion batteries.

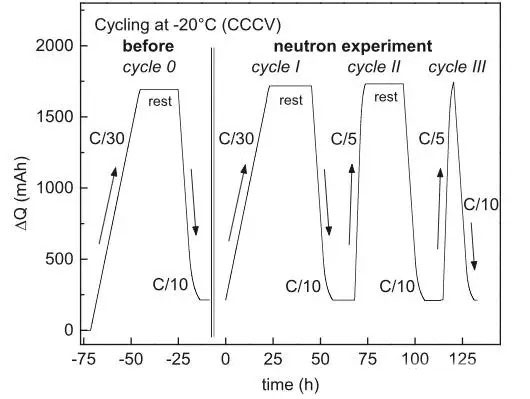

In the experiment, VeronikaZinth used NMC111/graphite 18650 battery to study the lithium evolution behavior of lithium ion battery at low temperature. During the test, the battery was charged and discharged as shown in the following figure.

The figure below shows the phase change of the negative electrode at different SoCs during C/30 rate charging in the second charging cycle. It can be seen that at 30.9% SoC, the phase of the negative electrode is mainly LiC12, Li1-XC18 and a small amount of LiC6. The composition, after the SoC exceeds 46%, the diffraction intensity of LiC12 continues to decrease, while the strength of LiC6 continues to increase. However, even if the charging is finally completed, since only 1503mAh (normal temperature capacity 1950mAh) is charged at a low temperature, LiC12 continues to exist in the negative electrode. If the charging current is reduced to C/100, the battery can still obtain a capacity of 1950mAh at a low temperature, which indicates that the capacity reduction of the lithium ion battery at a low temperature is mainly caused by deterioration of kinetic conditions.

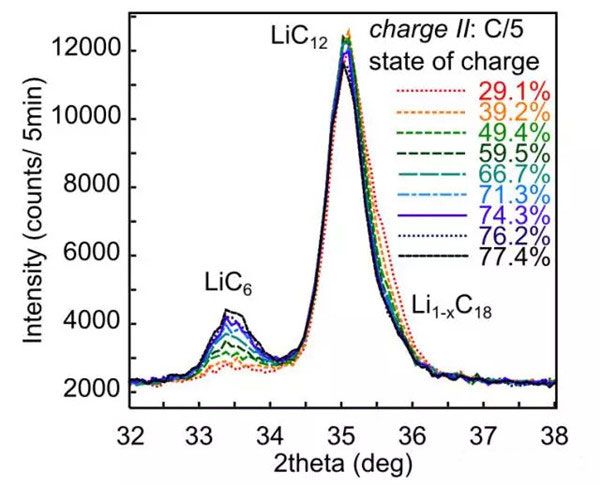

The figure below shows the phase change of the negative graphite in the process of charging at C/5 rate at a low temperature of -20 °C. It can be seen that the phase change of graphite is significantly different compared to the C/30 rate charging. It can be seen from the figure that at SoC>40%, the intensity of the LiC12 phase of the battery is significantly slower under the C/5 charging rate, and the LiC6 phase intensity is also significantly weaker than the C/30 rate charging. It is shown that at a relatively high rate of C/5, less LiC12 is continuously intercalated into lithium and converted to LiC6.

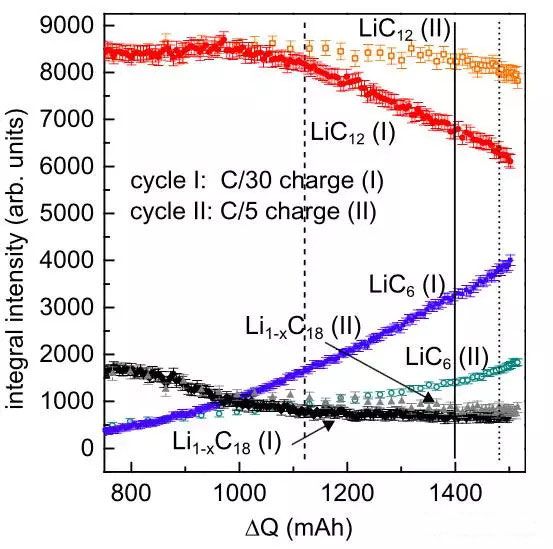

The following figure shows the phase change of graphite anodes when charging at C/30 and C/5 rates respectively. It can be seen from the figure that the Li-depleted phases Li1-XC18 are very similar for two different charging rates. The difference is mainly reflected in the two phases of LiC12 and LiC6. It can be seen from the figure that the phase change trend of the anode in the negative electrode at the two charging rates is relatively close. For the LiC12 phase, when the charging capacity reached 950mAh (49% SoC), the change trend began to appear different. When reaching 1100mAh (56.4% SoC), the LiC12 phase at the two magnifications began to show a significant difference. When C/30 is charged at a small rate, the falling speed of LiC12 phase is very fast, but the falling speed of LiC12 phase is much slower at C/5 rate, which means that the lithium kinetic conditions of the negative electrode are deteriorated at low temperature. The rate at which LiC12 is further intercalated to form a LiC6 phase is reduced. Correspondingly, the LiC6 phase increases very rapidly at a small C/30 rate, but is much slower at the C/5 rate. This shows that at the C/5 rate, less Li is embedded in the crystal structure of the graphite, but it is interesting that the charge capacity of the battery at C/5 charge rate (1520.5mAh) is lower than that under C/30 charge rate. The capacity (1503.5mAh) is higher, and the extra Li that is not embedded in the graphite negative electrode is likely to precipitate on the graphite surface in the form of metallic lithium. The static process after charging is also confirmed from the side. a little.

The figure below shows the phase structure of the graphite negative electrode after charging and after being left for 20h. It can be seen that at the end of the charging, the phase of the graphite negative electrode is very different under the two charging rates. At a large C/5 rate, the proportion of LiC12 in the graphite negative electrode is higher, and the ratio of LiC6 is lower, but after standing for 20 hours, the difference between the two has become very small.

The figure below shows the change of graphite anode phase during the 20h shelving process. It can be seen from the figure that although the phase of the two negative electrodes is still very different at the beginning, with the increase of the holding time, the two kinds of charging The phase of the graphite negative electrode at the magnification has become very close. During the shelving process, LiC12 can be continuously converted to LiC6, indicating that Li will remain in the interior of the graphite during the shelving process, and this part of Li is likely to be metallic lithium precipitated on the surface of the graphite anode at low temperature. Further analysis showed that the lithium intercalation degree of the graphite negative electrode was 68% at the end of charging at C/30 rate, but the lithium intercalation degree increased to 71% after the shelf life, and increased by 3%. At the end of the C/5 rate, the lithium intercalation degree of the graphite negative electrode was 58%, but it increased to 70% after being left for 20 hours, and the whole was improved by 12%.

The above studies have shown that when charging at a low temperature, the kinetic conditions are deteriorated, which not only causes a decrease in the battery capacity, but also causes a decrease in the lithium insertion rate of the graphite and precipitates metallic lithium on the surface of the negative electrode. Although after a period of suspension, this part of lithium metal can also be embedded inside the graphite again, but in actual use, the shelf time is often short, and it cannot be guaranteed that all the metal lithium can be embedded in the graphite again, which may cause some metal lithium to remain in the negative electrode. The surface will not only affect the capacity of the lithium-ion battery, but also may cause lithium dendrites that are harmful to the safety of the lithium-ion battery. Therefore, it is necessary to avoid charging the lithium-ion battery at a low temperature, and it is necessary to use it at a low temperature, small current, and after the end of charging, ensures a sufficient hold time to eliminate the metallic lithium of the graphite negative electrode.

The page contains the contents of the machine translation.

- Prev Article: Waterma receives 1.1 billion battery pack assembly purchase order

- Next Article: Ternary material battery will take the future

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News