Pouch Cells Lithium-ion Battery – Battery Type

Sep 11, 2019 Pageview:1784

Batteries, in general, have become the main source of energy in the world today. Just look around, and you will discover batteries power many of the devices being used across the globe. From cell phones to wristwatches, military to medical equipment, all are powered by batteries.

For this reason, the market for batteries has grown and widened rapidly. There is no place in the world where you will not find batteries.

Apart from that, competition among manufacturers has increased as well. There always something new coming up on the market in the battery industry. The main focus is often on performance and durability.

Lithium-ion batteries are considered among the most powerful chemistries. They can run longer in a day than other batteries. And they too, come in different capacities and types. Consider the following;

Types of Battery Cells

Different devices are designed for different types of batteries. In this case, type means the physical construction and appearance of the battery. There are three many divisions of batteries in this regard:

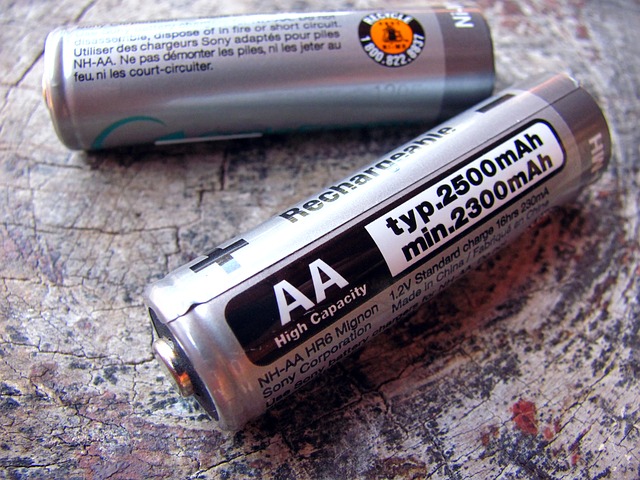

Cylindrical

This type continues to be one of the most common packaging styles. Whether in primary or secondary cells, cylindrical construction has taken the lead.

One of the reasons for this popularity is the ease of manufacture. There is nothing much needed to produce cylindrical batteries. Apart from this, they come with good mechanical stability. You will get very few cases of these batteries bending or splitting. They can withstand high internal pressured and stay without any deformation.

Many lithium cylindrical batteries are made with a positive thermal coefficient (PTC) switch. As such, they can cut current flow when exposed to excessive current when, for instance, the polymer heats up. And when everything comes back to normal, and the short is removed, the PTC resumes its conductive state.

Another great advantage of most cylindrical batteries is that they feature a pressure relief mechanism. As such, even the simplest designed utilizes a membrane seal. In case of high pressure, the seal ruptures, allowing the batteries to endure more. But a leakage may occur during this process leading to a dry-out. This is why some designs come with re-sealable vents with a spring-loaded valve. And these are the most preferred type.

Modern Li-ion cells are constructed with Charge Interruptive Device (CID). Its function is to physically and irreversibly disconnect the cell whenever unsafe pressure builds up.

Cylindrical batteries have good cycling ability as well. Consider 18650 batteries, for instance. They are the most powerful cylindrical Li-ion batteries. They are used in power tools, medical instruments, laptops, and e-bikes. They allow for variations, depending on the manufacturer.

Button Cell

Also, known as coin cells, some batteries were common for portable devices in the 1980s. The batteries were stacked with cells inside a tube to achieve higher capacity. They were common in cordless telephones, medical devices, and airport security wants.

These batteries are quite small and inexpensive to build. Despite that, they are not very common as they have given in to more conventional formats. They are not the ideal battery type because of safety issues. When charged rapidly, for instance, they swell easily. They have not safety vent and can only take in a 10 – 16-hour charge, except for newer designs.

Most of them are non-rechargeable. They can be found in medical implants, hearing aids, car keys, and memory back-up.

Pouch Cell

This is a design that was introduced in 1995. Instead of using a metallic cylinder, and glass-to-metal electrical feed-through, they are designed with conductive foil-tabs welded to the electrodes. They were then, situated to the outside, and completed sealed off.

The cells come in a simple, flexible, and lightweight design, a solution to many batteries. In some, there is a recommendation for some stack pressure. However, there must be an allowance for swelling.

One of the biggest successes of this design is the efficient use of space. It achieved 90-96% of packaging efficiency, way more than what you can say about other batteries. They don’t have a metal enclosure, a factor that reduces weight.

These batteries are commonly used in consumer, military, and automobile applications. There is no standardized pouch. It is upon the manufacturer to come up with their design.

Advantages and Limitations of Pouch Cells Li-ion Battery

Advantages

· Portability. As stated above, pouch cells can take any design. They are used in specific equipment because they can be designed to fit anywhere. There is no standard pouch.

· Lightweight. If you have devices like drones and other hobby gadgets, you want them as light as possible. Pouch cells are light because they don’t have any metal casing.

· Very powerful. Devices as the ones mentioned above require high current to operate. Most pouch cells are Li-polymer. As such, they are considered very powerful even as they are small. Drones and bobby gadgets require small, light, but powerful batteries, which make this type the perfect choice. Larger cells ranging up to 40Ah serve in storage systems.

Disadvantages

· Extreme swelling. This is the biggest downside of this type. Users have reported more than 3 percent swelling incidences. Even though they can be stacked, one must be careful to leave room for swelling. Smaller batteries can grow 8-10% over 500 cycles while larger ones can go up to 5000 cycles to expand the same.

· some cases, it can even break the display and electronic circuit boards. If exposed to extreme heat, the gasses can ignite. You are advised to discontinue use.

· Expensive to manufacture. These batteries are manufactured for specific equipment because they are very expensive. As such, they are not very common, either.

What are pouch cells lithium batteries used in?

Pouch cell lithium batteries are growing in popularity by the day. They serve similar applications to the prismatic cell. Because of their high energy capacity, they are used in consumer, military, and automobile applications.

Final Thought

The chemistry behind pouch cells utilizes laminated architecture in a bag. It is light and cost-effective in terms of performance. However, exposure to humidity and high temperature can reduce its performance. They are very powerful and come in different sizes to meet the needs of users.

- Prev Article: Overpack Lithium Batteries – Package Guidance

- Next Article: Dry Cell Battery Vs Lithium Battery-Definition, Characteristics

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News