Is Lithium Battery Recyclable?

May 29, 2019 Pageview:1886

Battery recycling is the recycle and reprocessing activity of batteries aimed at minimizing the number of batteries being disposed of as solid or material waste. As you also know that batteries contain numerous toxic chemicals and heavy metals and that’s why disposing of the batteries has raised concerns over water pollution and soil concentration. Considering this, batteries require recycling in order to comply with health and environmental benefits.

At present, there are different types of batteries and some can be recycled. If you are wondering about whether the lithium-ion battery can be recycled, then you are in the right place.

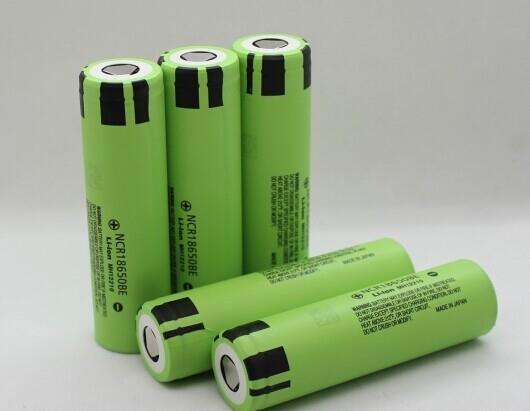

There is no doubt that lithium-ion batteries or also known as rechargeable batteries are quite popular these days because they offer more energy as compared to other types of rechargeable batteries. They are capable to hold the charge much better than their counterparts. The simple answer to your question – “Can lithium batteries be recycled?” is YES. However, they aren’t recyclable in the regular recycling bin. Nevertheless, lithium-ion batteries contain less toxic as compared to other types of batteries and this makes the quite easier and quicker to recycle.

The lithium battery recycling challenge

Even though lithium-ion batteries are recyclable, there are recycling challenges about these batteries you might don’t know about them.

Rising oil process, great demand for urban vehicles, and spotlight on sustainable transportation have kick-started a considerable trend towards automotive electrifications like electric vehicles (EVs) and hybrids vehicles. Plus, many studies suggest that by 2020, EVs and hybrid vehicles are probably to account for more than seven percent of the global transportation market. On another side, the growing popularity of EVs and hybrid cars is thriving the worldwide demand for lithium-ion batteries. Have you ever wondered what about when these vehicles arrive at the end of their lives? So, can lithium-ion batteries be recycled easily?

There is no doubt that there are various challenges that are probably to impact the supply of lithium in the future. Even though there is enough quantity of lithium resources out there worldwide to fulfill the demand, approximately 70% of the worldwide lithium deposits are found in South America’s region, which includes Argentina, Bolivia, and Chile. Considering this factor, it poses an innate risk due to raw material accessibility available only in a particular geography. Instability or turbulence of the government in these areas can significantly affect the lithium supply and have a great impact on the lithium-ion battery price, and ultimately, the vehicle cost.

The good news is that OEMs are doing some efforts to overcome the lithium dependency thought reuse of lithium-ion batteries and via the recycling these batteries after they completed their lifespan. However, recycled lithium-ion batteries are as much as 5 times the cost of the production of lithium from the least expensive brine based procedure.

Even though lithium-ion batteries are 100% recyclable, at present, recycled lithium accounts to the slag and is utilized for non-automotive purposes, which include construction. The battery recycling market is greatly price driven as latest and modern technology isn’t a serious differentiating factor. In fact, all the main participants execute the same level of modern technology in their offerings. Thus, the main differentiating factor is price.

Is innovation making lithium-ion batteries harder to recycle?

At present, battery manufacturers make lithium batteries as affordable as they can. In this attempt, they are eliminating valuable elements or parts that make these batteries sensible to recycle as per the Electric Power Research Institute.

Recently, the program Manager for EPRI’s, Ben Kaun said: “lack of the recycling adds an end-of-life cost to lithium batteries”. Plus, he added that “Presently in lead-acid 98%, these systems are capable to get restored and changed into the new lead-acid batteries”. And Lithium-ion is quite different. There is not the similar level of high-value materials and plus, lots of innovations going currently in lithium batteries are really to drive out the left behind high-value materials such as cobalt and others, out of these systems.

As the cobalt cost is quite high and that’s why companies are making an effort to redesign batteries to reduce cobalt. That’s why batteries are cheap. Further, Kaun said that “without crucial contents, recyclers have very little incentives in order to capture the used batteries”.

Sadly, Lithium batteries haven’t yet had a similar kind of recycling foundation that in the lead-acid batteries. Plus, battery owners sure to left with only option disposal cost rather than recycling incentive if there is no recycling market.

A new way to recycle lithium-ion batteries

The cathodes in the lithium batteries generally used in electric-based vehicles are made of metal oxides, which contain cobalt. It is metal found in the limited supplies in one of the worldwide more precarious countries.

The good news is that chemical engineering students from Michigan Technological University have finally found a new way of recycling lithium-ion batteries by utilizing an established practice of processing minerals.

Led by an assistant professor of this branch, the team implemented mining technology of the 20th century and this technology separates metal from ore to lithium battery recycling procedure. The practice was utilized to separate the parts of the battery like its casing and the cathode and anode coatings including the crucial lithium-ion metal oxide.

After separation of valuable components, all of the battery elements or parts can be returned to the battery manufacturer so that they can re-make them into new batteries. The process is quite beneficial because it is not just energy-efficient procedure, but also cheaper as compared to the utilizing virgin materials.

The professor further said that “we saw a chance to use an already existing technology to address rising and emerging recycling challenges. We utilize the basic gravity separations in order to separate copper from aluminum and further, we utilize froth flotation to restore critical materials, which include cobalt, lithium, and graphite”.

Well, lithium-ion batteries are considered to be the best alternative to conventional lead-acid types because of their energy density and longevity. However, they can impact an environmental threat or risk if there is no good way to dispose of the lithium-ion batteries safely.

- Prev Article: Drone Lipo Battery Referal

- Next Article: Lithium-ion battery large capacity analysis

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News