-

1) What is a Battery Module?

-

2) Modular Lithium Battery Pack

-

3) 12V Lithium Ion Battery Module

-

4) The Difference Between Lithium Battery Module and PACK

-

5) Lithium Ion Battery Module Design

-

6) Lithium Ion Battery Charger Module

Lithium Ion Battery Modules Manufacturer, Battery Modular & Pack

Mar 23, 2021 Pageview:2690

1) What is a Battery Module?

Lithium battery module is composed of several to hundreds of cells in parallel and in series. In addition to the mechanism design, the battery management system and thermal management system can form a relatively complete lithium battery pack system.

Lithium Ion Battery Module

The battery module is an adjustable module with high combination flexibility. In the absence of protection plate and balance system, the remaining capacity of 100% DOD cycle is over 80% for more than 2800 times. It is safer, more environmentally friendly, more stable and more efficient.

Capacity: module unit

Length: 400mm

Width: 150mm

Height: 210mm

Nominal voltage (V): adjust to demand

Weight of battery pack: ≤50 Kg

Standard charging current: 0.3C

Maximum continuous discharging current: 1C

Operating temperature range: -20~55℃

Cycling life(times): 80%DOD≥4000 times

lithium titanate battery Module

Based on graphene technology, Lithium titanate battery product has a combination performance of high power density of super capacitor and high energy density of lithium battery, which is more suitable for high power, high energy, wide temperature range application conditions. Compared with lithium iron phosphate batteries, it has high ratio (maximum 10 c), long cycling life, wide working temperature range, etc. The product can be widely used in power system, new energy vehicles, rail transit and other fields.

2) Modular Lithium Battery Pack

Lithium batteries produced by many lithium battery manufacturers have a fixed range value, which is set according to the demand. However, the voltage required by the actual equipment is different. In order to provide the corresponding voltage or capacity for the lithium battery, it can only be achieved by connecting lithium batteries in series and parallel. This kind of demand is called modularization demand, and the lithium battery made according to the modularization demand is called modularization lithium battery pack, or customized lithium battery module.

Low Temperature Charge and Discharge Lithium Iron Phosphate Battery Pack 25.6V 40Ah

Product number: HPB-212-11

Battery specification: 25.6V40Ah

Cell model: L148F20C-20000mAh-3.2V

Nominal voltage: 25.6V

Nominal capacity: 40000mAh

Battery dimension: 360*260*125

Internal resistance: ≤50m?

Battery weight: 15kg

Charging current: 8000mA(0.2C)

Continuous discharging current: 8000mA

Protective current: 300A

Charging voltage: 29.2V

End-off voltage: 20.0V

Cycling life: charge and discharge condition: charge at 0.2C, discharge at 0.2C, ≥1000 times

Charging temperature: -20~45℃

Discharging temperature: -40~60℃

Storage temperature: -30~45℃

Temperature protection: 65±5℃

Main features

1. It can work normally under severe conditions at -40℃. Capacity retention rate ≥70%

2. Charge the battery pack at -20℃.

3. At normal temperature, the battery can discharge up to 40C.

product_398_id

3) 12v lithium ion battery Module

The 12V lithium ion battery module is generally composed of 3 or 4 cells with a single voltage of 3.2V ~ 3.7V. The module is usually made of 18650 cylindrical lithium ion cells. The module photo frame is made of PP+ABS material. The module is fixed by screw, the module bus is connected with nickel-plated steel sheet, and the bus is connected with the cell by spot welding.

Low Temperature Charge and Discharge Lithium Iron Phosphate Battery Pack 12V 20Ah

Product number: 03EQ112-03

Cell model: LA148F20C/3.2V/20000mAh

Battery specification: LA148F20C-2S1P/6.4V(DC12V)/20Ah

Nominal voltage: DC12V constant voltage

Nominal capacity: 20Ah

Charging voltage: DC input 12V

Charging current: ≤2A

Discharging current: 3A

Instant discharging current: 10A

End-off voltage: 4V

Internal resistance: ≤120mΩ

Battery weight: 2500g with shell

Product dimension: 180*175*70mm

Charging temperature: -20~45℃

Discharging temperature: -40~55 ℃

Storage temperature: -20~50 ℃

Temperature protection: 60℃±5℃

Product features

Communication function: smbus communication protocol; Real-time monitor of battery voltage, current, capacity, temperature and other information

Quick connection: Adopt push-pull self-lockingspecial connector, which is fast, safe and reliable.

Data communication management: Adopt precise IC+TI charger management chip, accurate data transmission and accurate temperature control to try best to eliminate security risks.

Charging: It can charge at -20 degree low temperature; Meet the field charging needs.

The battery pack has good security, nice low-temperature performance and long cycling life.

The battery pack has long cycle life, which conforms to the principle of low carbon, energy conservation and environmental protection.

Waterproof and shock-resistant: Fill in the shock-resistant structure inside the aluminium alloy housing to satisfy the requirements of good security and high reliability.

4) The Difference Between Lithium Battery Module and PACK

As we all know, the automation degree of assembly line is an important factor determining product quality and production efficiency in the whole process from lithium battery cell to automation module to PACK production line. In recent years, with the increase of experience and the improvement of automatic integration ability, domestic high-end intelligent equipment manufacturers have made great achievements in building automatic/semi-automatic assembly line of power batteries, automatic equipment integration, information acquisition and transmission (MES), hardware and software management system of unmanned workshop.

Lithium battery module is composed of several to hundreds of battery cells in parallel and in series. In addition to the mechanism design, the battery management system and thermal management system can form a relatively complete lithium battery pack system. In general, the automated assembly process for modules begins with choosing the cell, whether it is a pouch cell, a square cell, a cylinder cell, or an 18650 cell.

PACK means package, encapsulation and assembling. It includes processing, assembly and packaging. The PACK production line generally performs only two functions: transmission and detection. At present, semi-automatic PACK assembly line is widely used by manufacturers. It is mainly used for on-line, off-line, inspection, in-plant transmission and packaging of PACK.

With the rapid development of the industry, more and more customers require to integrate the PACK and MES system of module together for better management and fast query, which is a big challenge for the system integrator. At the same time, battery enterprises choose automation module and PACK production line not only for investment and return, but also for the long-term development of the strategic layout.

Lithium battery cell(Cell)

The basic unit of a lithium battery can be used for charging and discharging. The anode, cathode, separator, and electrolyte are placed in a square aluminum or cylindrical steel shell.

Lithium battery module(Module)

In order to protect cells from external shock, heat and vibration, a certain number of cells are connected together and put into a frame to form a battery pack (Assembly).

Lithium battery pack(PACK)

The process of assembling a lithium battery cell into a battery pack is called PACK. It can be a single battery, or battery module connected in series and parallel.

PACK consists of battery pack, bus, flexible coupling, protective board /BMS, exterior package, output (including connector), highland barley paper, plastic bracket and other auxiliary materials.

Lithium battery PACK features

The battery PACK requires a high degree of consistency (capacity, internal resistance, voltage, discharge curve, cycling life)

The cycling life of a battery PACK is lower than that of a single battery.

Use under limited conditions (including charging, discharging current, charging mode, temperature, etc.)

After the lithium battery PACK is formed, the battery voltage and capacity are greatly improved. Therefore, it must be protected and monitored for charging balance, temperature, voltage and overcurrent.

The battery PACK must meet the voltage and capacity requirements of the design.

5) Lithium Ion Battery Module Design

The lithium battery module is the intermediate product between the lithium battery cell and pack formed by the combination of lithium ion battery cells in series and parallel and the monitoring and management device of single battery. The structure must support, fix and protect the cells, which can be summarized into three major items: mechanical strength, electrical performance, thermal performance and fault handling capacity.

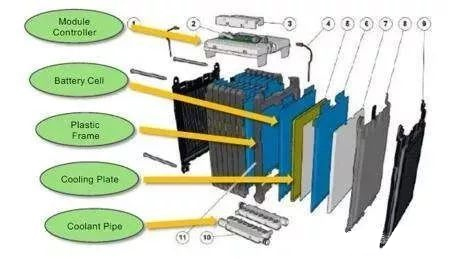

The basic components of a battery module include: module controller, battery cell, conductive connector, plastic frame, cooling plate, coolant pipe, pressing plate at both ends and a set of fasteners to hold these components together. In addition to gathering the single cell and providing a certain pressure, the pressing plates at both ends are often designed with the fixed structure of modules in pack.

Structural design

Reliable structure: anti - vibration and anti – fatigue

Controllable process: no over-welding or insufficient solder, to ensure 100% no damage to the cell.

Low cost: the automation cost of the PACK production line is low, including production equipment and production loss.

Easy to disassemble: The battery pack is easy to maintain and repair. It has low cost, and the battery cell has good cascade utilization performance.

Necessary heat transfer isolation to prevent runaway heat from spreading too quickly. It can also be considered in the pack design

At present, cylindrical cell module PACK efficiency is about 87%, the systematic PACK efficiency is about 65%; The PACK efficiency of pouch cell modules is about 85%, and the systematic PACK efficiency is about 60%. The modular PACK efficiency of the square cell is about 89%, and the systematic modular PACK efficiency is about 70%. The monomer energy density of the pouch cell can be better than that of the cylinder and the square, but the module design has higher requirements and the security is not easy to control. All these are problems that need to be solved by structural design.

General module optimization approach: Improving space utilization is also an important way to optimize modules. Power battery PACK enterprises can improve the module and thermal management system design to reduce the distance between the cells, so as to improve the utilization of the space inside the battery box. Another solution is to use new materials. For example, the bus in a power battery system (a bus in a parallel circuit, and usually made of copper plates) is replaced with aluminum by copper, and the plate metal for the module fasteners is replaced with high-strength steel and aluminum, which also reduces the weight of the power battery.

Thermal design

The physical structure of the soft cell determines that it is not easy to explode. Generally, it won’t explode unless the shell withstand over pressure. Besides, when the inner pressure of the pouch cell is large, it will have decompression and leakage from the edge of the aluminum plastic film. The pouch cell also has the best structures of several cells for heat dissipation.

Electrical design: low voltage design + high voltage design

Low voltage design generally needs to consider several aspects of the function. Through the signal acquisition wiring harness, the battery voltage and temperature information is collected to the slave module control board or the so-called module controller installed on the module. Equalization function (active equalization or passive equalization or both) is generally designed on module controller. A small number of relay on-off control functions can be designed on the slave control board or on the module controller. Module controller and main control board are connected through CAN communication to transmit module information.

High voltage design is mainly on the cell connection in series and parallel, as well as the outside of the module, and the conductive mode between design modules. General modules only consider the connection mode in series. These high-voltage connections need to meet two requirements: first, the distribution of conductive parts and contact resistance between the cells should be uniform, otherwise, the monomer voltage detection will be interfered; Secondly, the resistance should be small enough to avoid wasting energy during transmission.

Safety design

Safety design can be divided into three retrograde requirements: good design to ensure that no accidents; If not, it needs advanced warning; When a failure has occurred, the design goal is to prevent accident from spreading too quickly.

The first objective is to achieve a reasonable layout, good cooling system and reliable structural design; For secondary targets, the sensor should be more widely distributed to every possible area for failure, so as to comprehensively detect the voltage and temperature, preferably to monitor the internal resistance of each cell. Last but not least, fuse can be set through the cell and module, and firewall can be set between module and module, design strength redundancy to deal with the possible structural collapse after the accident. This is the direction of high performance pouch modules.

Light weight design

Lightweight design main purpose is to pursue the endurance mileage and to eliminate all unnecessary burden. It will be better if light weight can be combined with lower costs. There are many ways for lightweight, such as increasing the energy density of the cell; In the details of the design, ensure the strength of the shell, and then pursue the lightweight structural parts (such as choosing thinner material, digging larger holes in the plate); Replace sheet metal parts with aluminum; New materials with lower density are used to make shells and so on.

Standardized design

Standardization is the long-term pursuit of large industry. Standardization is the cornerstone of cost reduction and interchangeability improvement. Specifically, there is also a great purpose of power battery module cascade utilization. However, the reality is that monomers are not yet standardized, so modules are further away from standardization.

6) Lithium Ion Battery Charger Module

The charging module of lithium ion battery is used for charging a single lithium battery or multiple lithium batteries in parallel. The general charging module of lithium ion battery consists of charging current sampling circuit, charging switch tube, integrated control circuit, charging voltage sampling circuit, etc.

The charging sampling circuit can set the constant charging current of the charging module according to the capacity of the lithium battery to be charged. The voltage sampling circuit can set the constant charging voltage output from the general charging module according to the number of lithium batteries in series to be charged. The function of integrated control circuit is to realize the best charging of lithium battery by controlling switch. After the charging starts, charge the lithium battery with a constant current. When the battery voltage reaches the setting constant charging voltage, it will be automatically transferred to constant voltage charging to ensure the lithium battery is safe, fast and fully charged.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News