-

1) What is a Cylindrical Battery?+

- 1. Definition of cylindrical battery

- 2. Cylindrical battery structure

- 3. Advantages of cylindrical lithium battery

- 4. Cylindrical battery anode material

- 5. Cylindrical battery cathode material

-

2) Cylindrical Lithium Ion Battery Cells+

- 1. Cylindrical lithium ion battery brand

- 2. Type of cylindrical lithium ion cell

-

3) Cylindrical Lithium Ion Battery Market

-

4) Prismatic Cell Vs Cylindrical

-

5) Pouch Cells Vs Cylindrical

Cylindrical Lithium Ion Battery

Dec 26, 2019 Pageview:2913

1) What is a Cylindrical Battery?

1. Definition of cylindrical battery

Cylindrical lithium battery is divided into lithium iron phosphate, lithium cobalt oxides, lithium manganese, cobalt manganese mixture and ternary material system. Battery shell is divided into steel shell and polymer shell. Different material system battery has different advantages. Currently, the main cylinder is given priority to cylindrical lithium iron phosphate battery with steel shell, which has the performances of high capacity, high output voltage, good charge and discharge cycle performance, stable output voltage, large current discharge, stable electrochemical performance, nice safety, wide working temperature range and environmentally friendly. It is widely used in solar energy lamps, lawn lamps and lanterns, backup power, electric tools and toys model.

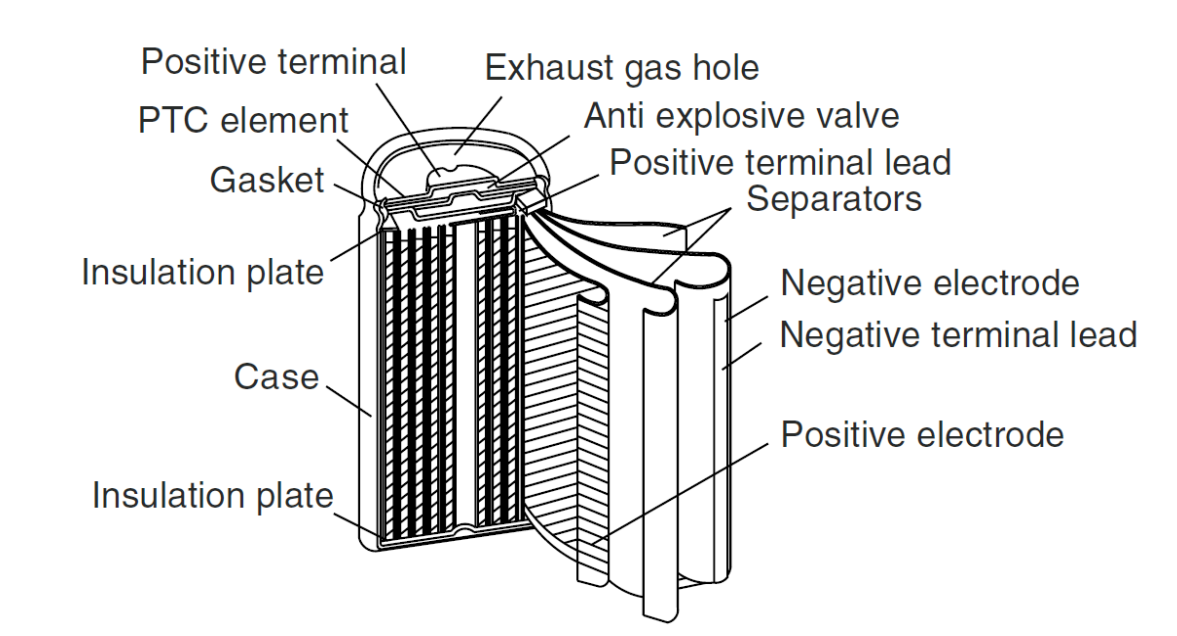

2. Cylindrical battery structure

A typical cylindrical battery structure includes: shell, cap, anode, cathode, separator, electrolyte, PTC element, gasket, safety valve, etc. Generally, the battery shell is the cathode of the battery, and the cap is the anode of the battery. The battery shell is made of nickel plate.

3. Advantages of cylindrical lithium battery

Compared with soft pack and square lithium battery, cylindrical lithium battery has the longest development time, higher standardization degree, more mature technology, high yield and low cost.

The battery has mature production process, low PACK cost, high product yield and good heat dissipation performance.

The cylindrical battery has formed a series of international standard specifications and models with mature process, which is suitable for continuous mass production.

The specific surface area of the cylinder is large and the heat dissipation effect is good.

Cylindrical batteries are generally sealed batteries. There is no maintenance problem during usage.

The shell of the battery can withstand high pressure, and there will be no such phenomenon as square, pouch battery puffed during usage.

4. Cylindrical battery anode material

At present, the mainstream commercial cylindrical battery anode materials mainly include lithium cobalt oxide (LiCoO2), lithium manganese (LiMn2O4), ternary (NMC), lithium iron phosphate (LiFePO4), etc. Batteries with different material systems have different characteristics, which are compared as follows:

| Item | LiCoO2 | LiNiCoMnO2 | LiMn2O4 | LiFePO4 |

| Tap density(g/cm3) | 2.8~3.0 | 2.0~2.3 | 2.2~2.4 | 1.0~1.4 |

| Specific surface area(m2/g) | 0.4~0.6 | 0.2~0.4 | 0.4~0.8 | 12~20 |

| gram volume (mAh/g) | 135~140 | 140~180 | 90~100 | 130~140 |

| Voltage platform(V) | 3.7 | 3.5 | 3.8 | 3.2 |

| cycle performance | ≥500times | ≥500times | ≥300times | ≥2000times |

| Transition metal | little | little | a lot | abundant |

| Material cost | very expansive | expensive | cheap | cheap |

| Environmental protection | contain Co | contain Ni and Co | non-toxic | non-toxic |

| Safety performance | bad | good | better | best |

| Scope of application | small and medium size battery | small batteries/small power battery | power battery, low cost battery | power battery/power supply with super capacity |

| Advantages | Stable charge and discharge, simple production process | Stable electrochemical performance and good cycling performance | Abundant manganese resource, relatively cheap, good safety performance | High safety, environmental protection, long life |

| Disadvantages | Cobalt is expensive and has low cycle life | Cobalt is expensive | Low energy density, poor electrolyte compatibility | Poor low-temperature performance, low discharge voltage |

5. Cylindrical battery cathode material

Cylindrical battery cathode materials can be divided into six categories: carbon cathode materials, alloy cathode materials, tin-based cathode materials, lithium transition metal nitride cathode materials, nanometer materials and nanometer cathode materials.

Carbon nanometer material cathode material: currently, the cathode materials that have been actually used in lithium ion batteries are basically carbon materials, such as artificial graphite, natural graphite, mesophase carbon microspheres, petroleum coke, carbon fiber, pyrolysis resin carbon and so on.

Alloy cathode materials: include tin-based alloy, silicon-based alloy, germanium-based alloy, aluminum-based alloy, antimony-based alloy, magnesium-based alloy and other alloys. Currently, there are no commercial products.

Tin - based cathode material: tin - based cathode material can be divided into tin oxide and tin - based composite oxide. Oxide is the oxide of various valence tin metals. There are no commercial products.

There are no commercial products for lithium transition metal nitride cathode materials.

Nanometer materials: carbon nanotubes, nano-alloy materials

Nanometer cathode material: nanometer oxide material

2) cylindrical lithium ion battery Cells

1. Cylindrical lithium ion battery brand

Cylindrical lithium battery is popular among Japanese and Korean lithium battery enterprises, and there are also some large-scale enterprises in China that produce cylindrical lithium battery. The earliest cylindrical lithium battery was invented by Japanese company SONY in 1992.

Well-known cylindrical lithium ion battery brand: SONY, Panasonic, Sanyo, Samsung, LG, Wanxiang A123, Bic, Lishen and so on.

2. Type of cylindrical lithium ion cell

Cylindrical lithium ion cell is usually represented by five digits. Starting from the left, the first and second digits are the battery diameter, the third and fourth digits are the battery height, and the fifth digit means circle. There are many types of cylindrical lithium batteries, including 10400, 14500, 16340, 18650, 21700, 26650 and 32650.

10440 battery

10440 battery is a lithium battery with diameter of 10mm and height of 44mm, which has the same size as AAA battery. This battery capacity is generally small, only a few hundred mAh, and is mainly used in mini electronic products, such as flashlight, mini stereo, amplifier and so on.

14500 battery

14500 battery is a kind of lithium battery with a diameter of 14mm and a height of 50mm. This battery is generally 3.7V or 3.2V. The nominal capacity is relatively small, a little larger than 10440 battery, which is normally 1600mAh. It has excellent discharge performance, and tends to be mainly used in consumer electronics, such as wireless audio, electric toys, digital cameras, etc.

16340 battery

16340 battery is a lithium battery with diameter of 16mm and the height of 34mm. Due to relatively small height but not small capacity, it is mainly used in the glare flashlight, LED flashlight, headlamp, laser lamp, illuminator, etc.

18650 battery

18650 battery is a lithium battery with 18 mm diameter and 65 mm height. It has a very high energy density, reached almost 170 watts/kg, so the battery has good cost performance. It has been widely used, because it is relatively mature lithium battery with good quality of all aspects of system stability. It is widely applicable to about 10 KWH battery capacity situations, including mobile phones, laptops and other small appliances.

21700 battery

21700 battery is a lithium battery with 21 mm diameter and 70 mm height. Because of its increasing size and space utilization, the cell energy density as well as the system can be improved, the volume energy density is much higher than 18650 batteries. It is widely used in digital, electric cars, balance car, solar lithium battery street lamp, LED lights, electric tools, etc.

26650 battery

26650 battery is a lithium battery with 26mm diameter, 65mm height, 3.2V nominal voltage and 3200mAh nominal capacity. This battery has excellent capacity and high consistency, has gradually become a replacement of 18650 battery, and tends to march in the power battery market.

32650battery

32650 battery is a lithium battery with a diameter of 32mm and a height of 65mm. This battery has a strong continuous discharge capacity, so it is suitable for electric toys, backup power supply, UPS battery, wind power generation system and wind and photovoltaic complementary power generation.

3) Cylindrical lithium ion battery Market

The technical progress of cylindrical lithium ion battery mainly comes from the innovation research and application progress of key battery materials. Through the development of new materials, further improve battery performance, quality and safety, but reduce cost. In order to meet the requirements of the downstream application on the improvement of battery specific energy, on the one hand, adopt the material with high specific capacity; on the other hand, increase charging voltage and adopt high voltage material.

Cylindrical lithium-ion battery develops from 14500 to 21700 Tesla battery. Recently, optimize the existing system of lithium ion power battery technology to meet the demand of new energy automobile scale development, focus on the development of new type of lithium ion power battery, improve the life span, safety, consistency, and key technologies, and synchronize new system development of power battery forward-looking research.

For the medium and long term development of cylindrical lithium ion battery, while continuously optimizing and improving the new lithium ion power battery, keep focusing on the research and development of new system power battery, which can significantly improve the specific energy, reduce the cost, and realize the utility and large-scale application of the new system power battery.

4) Prismatic Cell Vs Cylindrical

Battery shape: square size can be arbitrarily designed, while cylindrical battery cannot be compared.

Multiplier characteristic: the process limitation of welding multipole lead for cylindrical battery is slightly worse than that for square multipole lead battery.

Discharge platform: adopts lithium battery with the same anode and cathode materials and electrolyte. Theoretically, the discharge platform should be consistent, but the discharge platform of the square lithium battery is slightly higher.

Product quality: the manufacturing process of cylindrical battery is relatively mature, the defect rate of pole piece's secondary cutting is low, and the maturity degree and automation of winding process is good. The lamination process is still semi-manual at present, which has an adverse impact on the battery quality.

Electrode lead welding: cylindrical battery electrode lead is easier to weld than square lithium battery; Square lithium battery is prone to virtual welding which affects the battery quality.

PACK formation: cylindrical battery is easier to use, so PACK technology is simple with good heat dissipation effect; Square lithium battery PACK should solve the problem of heat dissipation.

Structural features: square lithium battery has poor chemical activity at the edges and corners, and the energy density of the battery in long-term usage is easy to decline, and its endurance time is short.

5) Pouch Cells Vs Cylindrical

The safety performance of pouch cell is good. The pouch cell is structurally packaged with aluminum-plastic film. In safety event, a pouch cell will generally burst with air, rather than explode like a steel or aluminum cell. It is superior to cylindrical lithium battery in safety performance.

Pouch cell has relatively light weight. The weight of pouch cell is 40% lighter than that of steel shell lithium battery with the same capacity, and 20% lighter than that of cylindrical aluminum shell lithium battery; The internal resistance of pouch cell is smaller than that of lithium battery, which can greatly reduce the self-consumption of battery.

Pouch cell has good cycle performance, and its cycle life is longer. The 100-cycle attenuation of pouch cell is 4% ~ 7% less than that of cylindrical aluminum battery;

It has flexible battery design, variable shape and small thickness. It can be customized according to customer needs, and develop new battery models, but cylindrical lithium batteries do not.

Compared with cylindrical lithium battery, pouch cell has poor consistency, high cost and easy for leakage. High cost can be solved through large-scale production, while leakage can be solved by improving the quality of aluminum plastic film.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News