Battery Technology Companies- Introduction, Development and Future

Aug 03, 2020 Pageview:983

Green energy products reflect a sense of superiority to the current carbon-based technology. It will not be long before consumers start grasping the potential it holds back. Tesla is already powering cars through lithium-ion batteries. Amazon has energized its entire delivery fleet through greener batteries. In a similar pursuit, companies have been planning to power deliveries and last-mile logistical services through electric vehicles. Since EVs guarantee an efficient, more eco-friendly approach, companies and consumers have been pushing towards the idea of an energy-powered economy.

The advent of a complete electronic lifestyle has made the growth of the battery sector imperative. From electric watches to electric cars, we as a community are transitioning from our evil ways to a world that promises more concrete progress. In light of their increasing essentiality, researchers have wandered into the domain of delving a battery technology that is economically feasible and ensures minimal environmental damage. For instance, half the cost of a Tesla comprises of the battery power packs. We must understand that for this technology to improve, concerted efforts are required in basing the technology on more practical grounds.

Which company has the best battery technology?

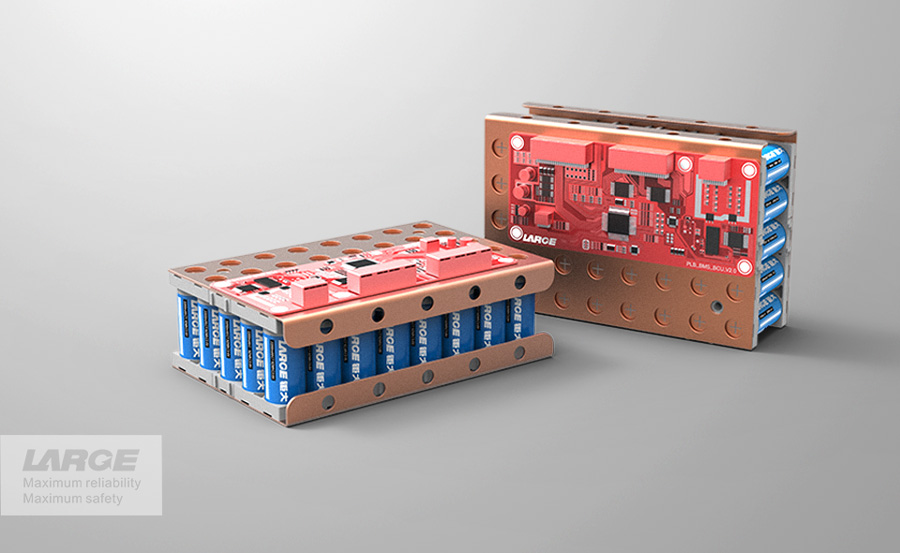

LG Chem is the oldest battery company that also utilizes the best battery technology. It offers alkaline and lithium-based batteries, amongst other offerings. Its cells are mostly employed in consumer electronics, bicycles, motorcycles, and household appliances. Many of these manufacturers have cracked a contract with car producers for an indefinite supply of Li-ion batteries. Tesla has the most exceptional battery technology in the automotive sector, reportedly. The company announced that it would be establishing a 'Gigafactory' in conjunction with Japanese electronics conglomerate Panasonic to produce in-house Li-ion batteries. Simultaneously, plans are in the pipeline to build lithium-ion factories across the world since China dominates the world market with its battery supply chain.

Battery innovation involves efficient energy density, safety, and cost reduction. Based on the factors mentioned earlier, companies that fit the checklist include A123 Systems Inc., BYD Company Ltd., and GS Yuasa Corporation.

How does Lithium-ion technology develop?

A lithium-ion (Li-ion) battery employs the use of advanced technology. The technology entails the utilization of lithium-ions as the most crucial component in its electrochemistry. The chemical composition comprises lithium-ion manganese oxide, lithium iron phosphate, and lithium nickel manganese cobalt oxide. The lithium atoms on the anode end are ionized during the discharged cycle and are further detached from their electrons. The ions transfer from the anode to the cathode by passing through the electrolyte, where it reconnects with electrons that induce electricity. The lithium-ions are tiny and can easily pass through the micro-permeable material between the cathode and the anode. The size of lithium is one third to the size of hydrogen and helium. Therefore, granted its size, it can move at a very high voltage and charge storage per unit mass and unit volume.

Different materials can be used as electrodes in lithium-ion batteries. The most frequent combination is lithium cobalt oxide, which is fixed at cathode and graphite used for the anode. Other cathode materials can include lithium manganese oxide and lithium iron phosphate. These materials are mostly used to power electric hybrid cars and automobiles. The typical material used for electrolyte is ether.

Lithium-ion batteries offer high energy density but pose a threat once damaged. Majority of the Li-ion battery manufacturers are based in Japan and China. Lithium-ion cells are produced for commercial and consumer purposes alike.

What is the next battery technology that could power the future?

Research teams are currently augmenting the performance and the capacity of lithium-based batteries. However, lithium-air technology is an improvement to the current battery situation. Lithium-air batteries require the use of oxygen to oxidize the anode. These batteries allow much greener energy storage and up to 10 times more capacity than a typical lithium-ion battery.

Conversely, the Li-Air batteries pose technological problems. The crisis of sudden death plagues the lithium-air batteries. The battery would die instantly or cease to work, thereby compromising its viability in energy-demanding projects. Lithium-metal based batteries are also an impressive development. These batteries promise four times more energy efficiency, thus reducing redundancy. It is cost-efficient; however, safety issues trigger significant concerns. Lithium-metal based cells tend to overheat, initiate fire, or explode, if damaged.

Battery technologies that are under pipeline include lithium-sulfur and silicon-carbon based cells. Since these projects are nascent and not commercially viable, it isn't easy to gauge how much traction they might gain. However, researchers have suggested that lithium-sulfur batteries can outperform Li-ion cells. Fellows from Monash University have developed a lithium-sulfur cell that can power a smartphone for up to 5 days. The newly developed technology is recorded to have a lower environmental impact and manufacturing costs.

Scientists are one step closer to developing silicon anode lithium-ion batteries. The problem with silicon-based batteries was the instability posed by silicon. However, a method has been formulated to establish a hybrid anode utilizing mesoporous silicon microparticles and nanotubes. The hybrid material improves the performance of the battery and has been sustainably produced from husky barley ash. The costs involved are low, and technology offers promise. The cell possesses ten times the capacity of an ordinary Li-ion battery. Further examinations are being conducted to test the viability of the project and estimate its production costs.

Companies are also venturing into manufacturing solar batteries. Solar cells reflect the most feasible option in terms of resources. However, the development process might entail exorbitant expenses.

Final Words:

Reports have suggested that most energy-based consumer products are affordable in the market. It will not be long before consumers are transitioning from carbon-based automobiles to cars powered through batteries. The ubiquitous presence of emissions and smoke will result in the heralding of a new era, an era in which the energy sector will exercise absolute control.

The future lies in the hands of those who can conquer it, and therefore, constant technological enhancement will enable us to grasp what is ours. A better world awaits as we retrace the havoc that has been wrecked on the environment recklessly.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News