How to rebuild medical lithium ion battery packs?

Mar 19, 2020 Pageview:1179

Can you rebuild medical lithium ion battery packs?

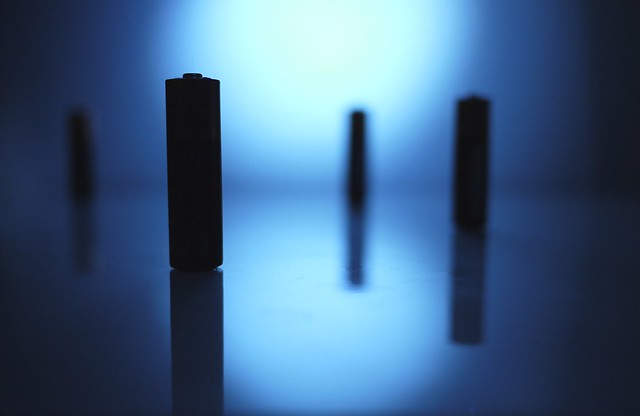

Most medical devices' battery packs are based on the 18650 Lithium ion battery. That is due to the fact that the 18650 batteries are produced in high volumes with a low cost per Wh, and it is the most mature form of any Lithium ion batteries on the market. When trying to rebuild a medical lithium ion battery pack there is some concern you should take into consideration:

Voltage.

Runtime requirements for the device.

Loading.

Size and weight limitation for the battery.

Environmental aspects.

Moreover, when rebuilding a medical lithium ion battery pack, you should design the battery pack to permit failure without any catastrophic events. Remember this battery pack is going to be used in a medical device wherein case of failure people might get hurt or worse. In addition, when rebuilding a medical lithium ion battery pack, you must follow the safety procedures to the point. As we have mentioned before, this pack will be used in a medical device, thus accuracy is the most important thing. If you have access to a place where you can test your battery pack after you rebuild it, then you should go perform that test. Otherwise, drive to your nearest lithium ion battery retail store and ask for your battery pack to be tested.

If for any reason, your rebuilt battery pack failed any test, throw it away immediately. Failure to do so could result in undesired outcomes, including hefty fines from your state.

How do you recondition a medical lithium ion battery packs?

Reconditioning a medical lithium ion battery pack is a delicate process that requires the presence of some tools and extreme precision. You would need the following tools before you start:

Safety glasses.

A voltmeter.

A lithium ion battery charger.

A USB cable. (Its type depends on your charger and battery outlets).

Another battery that is voltage dependent on your Lithium ion one that you need to recondition.

Some Crocodile clips.

Some paperclips.

Before proceeding, remember that reconditioning lithium ion batteries is a delicate procedure that requires extreme caution and professionalism. If you are not comfortable doing it, please refrain from doing the process and contact a professional specialist.

Now let us begin the reconditioning process:

Take a voltage reading with your voltmeter. This is an important step so you could know whether your lithium ion battery has entered the deep sleep mode and can be reconditioned or not.

Take the healthy battery that is dependent on your battery's voltage and put it in the circuit with the dead battery.

Get your crocodile clips and use them to connect the two batteries.

To have a working circuit go positive to negative when connecting the clips.

Leave the batteries in place and keep monitoring them for 15 minutes.

Make sure that both batteries are NOT getting too hot.

After these 15 minutes take a reading for your dead battery via the voltmeter, you should find that its reading became higher and it should accept charging now.

Give the battery that was once dead a full charge/discharge cycle. This process should take approximately three hours to charge.

After discharging the battery (try using a heavy load to discharge it like an LED lamp), put the battery into an airtight bag and put it into your freezer for approximately 24 hours.

After that perform a full charge once more on your battery until it reaches 100%.

Start using the battery. You should notice some improvement in its performance.

Do you need a custom service for medical lithium ion battery packs?

The short answer is yes. You need to customize your lithium ion battery packs for medical devices. The size of the medical devices plays a part in customizing the lithium ion battery packs. Moreover, the place where the medical device will be used puts huge restrictions on the design of the lithium ion battery packs.

Lithium ion batteries are used in almost all medical devices nowadays. For medical devices, two types of Lithium batteries are being used in them, the single-use ones and the rechargeable ones. The most commonly used type in medical devices; however, is the single usage type.

There are currently two types of Lithium ion batteries that are being used in medical devices. The "primary" lithium batteries that are disposable, and the "secondary" lithium batteries, which are the rechargeable lithium ion batteries. Depending on the medical device it is determined if the primary or the secondary types will be used. For medical devices that are mostly outside of the body, then the secondary lithium ion rechargeable batteries are used. Where access to a charger is easy. While for medical devices where access to a charger is hard, like the peacemaker; the primary lithium batteries are used. However, with the advanced technology in the Lithium batteries field, the primary lithium batteries offer a life span of almost 10 years, which reduced the number of operations the patient should undergo tremendously.

When designing a lithium ion battery for a medical device, some considerations must be followed:

Batteries should be economically priced, but have a high lifespan. (most medical lithium ion batteries have a lifespan of average 10 years)

Limited load current.

Very high capacity.

Have the potential to deliver high currents. (like the ones inside of a pacemaker, some have the ability to shock the patient in times of cardiac arrest)

It can be monitored 24 hours a day 7 days a week.

Safely insulated.

Leak-free. (if a battery leaks inside of a patient that could result in a patient's death)

Performance analysis devices must have access to these batteries at all times.

No Cobalt, nor any Cobalt derivative can be used in those batteries.

Batteries must be designed in a way to allow impedance checks at any time needed.

- Prev Article: How To Revive Dead 18650 Battery?-Cycle Life And Protection

- Next Article: How to properly dispose of a medical lithium ion battery?

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News