Anode Materials for Lithium-Ion Batteries Review – Performance and Effect

Mar 11, 2020 Pageview:1330

Nowadays, there are a lot of changes happening in the way in which batteries are made due to the advances in technology in general. Overall, the need to have renewable energy sources becomes more and more imperative by the minute, which is why the making of batteries is constantly improving.

For example, finding new materials to make more efficient batteries is of high importance so that the electrification of vehicles and devices expands to new horizons. Because of this, the elements with which a battery is made is very important in order to determine its functionality.

One of the criteria that can be used to review the way batteries work, as well as the quality of their performance, is by analyzing the materials used in their composition. Because of this, it’s important to define what are anode materials.

This type of material is referred to as the negative electrode found in lithium-ion batteries, and they are paired in a lithium-ion cell with cathode materials.

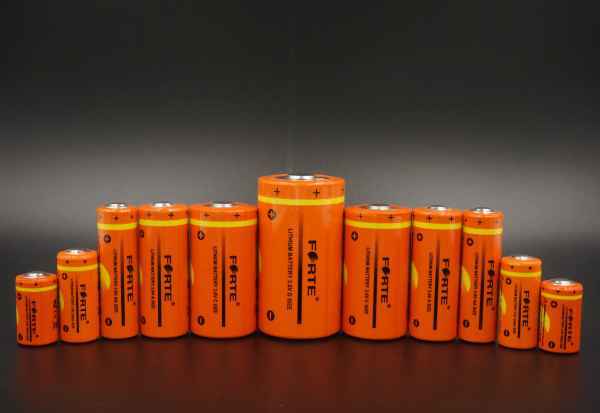

It is well known that one of the most frequently used types of batteries is lithium-ion, which is used on a wide range of technologies. Examples of this are electric vehicles, which use both an electric battery and a fuel engine.

Therefore, understanding the effect that anode materials have on them is quite important in order to determine the way in which these elements interact to guarantee a better functioning.

What anode materials are used in lithium-ion batteries?

Lithium-ion batteries use certain materials, but before we explain which of them are frequently found on these power sources, there are other things to discuss. Therefore, it’s important to take into account that there are some requirements that the materials need to have in order to be able to function on lithium-ion batteries. Thus, examples of this are the following:

- Low cost, so people have access to them

- Excellent conductivity and porosity, so they conduct the charges properly.

- Light weight, as well as long durability, to guarantee that they’re portable and offer good quality.

- Voltage match with the cathode of preference.

Likewise, the most used materials are LTO (lithium titanate), surface-functionalized Silicon, powdered graphene with high-performance properties, conductive additives, activated carbon and carbon black.

At the same time, one of the core elements used as an anode material is graphite powder, which is used in almost all lithium-ion batteries as an anode material.

The way this works is as an active material, which is used in this way because of a specific property that allows placing lithium-ion particles between its many layers. Thus, this is known as an electrochemical ability, which can maintain over thousands of cycles in batteries that work in an optimized way.

For this to happen, the graphite surface cannot be just any piece of this material. It must be compatible with the specific chemistry on the lithium-ion battery, which includes binders, salts, and solvents.

It’s also important to notice that this anode is not only made of graphite but also coated on copper foil. At the same time, the first element mentioned has a metallic sheen as well as a crystalline solid consistency, and black or grey color. Because of its composition, it is a high electricity conductor, which is why it can reach 25000 S/cm2 in the layer of just one crystal.

In order to solve the compatibility issue, some of the binders that are usually used are Polyvinylidene Fluoride (PVDF) and Styrene Butadiene Copolymer (SBR), which can come in contact with the aforementioned materials.

What is the performance of anode materials for lithium-ion batteries?

Nowadays, it is considered that lithium-ion batteries are one of the most efficient on the market regarding energy storage. This is due to the fact that they guarantee a source of energy to portable devices.

Although technologies are frequently changing with the new advances made by society and culture, these types of batteries are certainly many people’s favorites. Besides being a guaranteed power source, the materials with which they’re made (anodes) ensure a high density but also a complete lightness, which makes them viable for commercial purposes.

Like it was previously mentioned, taking into account not only the best materials on the market but the right combination of them (in terms of chemistry compatibility) is very important to ensure the quality of the battery. Nonetheless, it is still a fact that these are one of the most bought types of power sources.

What is the effect of anode materials for lithium-ion batteries?

In lithium-ion cells, the anode materials act like a host that allows intercalation and deintercalation on the lithium-ion, which happens during cycles of charge and discharge. Likewise, to select suitable anode materials that are able to function properly, there are some criteria:

-Irreversible loss on the low first cycle

-A high coulombic efficiency

-Diffusion of lithium-ion into and out of the anode, which must happen quickly

-The capacity to create and maintain a Solid Electrolyte Interface layer on cycling

-Ionic and electronic conductivity in high levels

-Specific capacity in high levels

-The less possible structural changes on charge and discharge

In other words, lithium is stored in the anode terminal and then transported to the cathode terminal, by the action of an electrolyte. This happens thanks to many processes, which include dispersion and ionic conduction.

With all of the aforementioned details about the effects of anode materials in lithium-ion batteries, it is no surprise that the process has become so refined with the advances of technology that nowadays these batteries are one of the people’s favorites.

The perfecting of the materials (especially anodes) used to make these batteries has allowed them to improve the way they work, serving as a guarantee of a reliable power source with not only a commercial value but an ecological one as well; because they form part of a series of developing new techniques that increase the people’s understanding of renewable energy sources.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News