Lithium-ion Battery Assembly Line-Assembling and Manufacturer

APR 11, 2020 Pageview:1725

The lithium-ion battery is being incredibly popular nowadays. The cells can be found in laptops, smart-phones, iPad, PDAs, and Power Bank. They are such standard batteries because they are the most energetic rechargeable batteries available.

These batteries are also being in the news lately as their technology is already in use for low power applications such as consumer electronics and power tools. These batteries can burst into flames occasionally. You know what just two or three batteries packs per million of problems but only happens in extreme cases. Extensive research and development have enhanced the technology to a stage where it seems it’s safe and reliable lithium-ion batteries. Now, let’s learn about Li-ion battery assembling line - for which you’ve come to this page.

How are lithium-ion battery assembled?

Electrode Coating: Anodes and cathodes in lithium cells are similar processes and identical equipment. On both sides of the metallic foils, there are active electrode materials coated conducting the current in and out of the cell. An anode is a form of Carbon, and the cathode is a Lithium metal oxide. These materials must be delivered to the factory in the form of black powder and the powder is an untrained eye. The worst thing is that it is indistinguishable from each other. This is the reason these two are processed in different two rooms.

The first stage is to mix electrode materials with a conductive binder to form a slurry that spreads on the surface of the foil and then passes into the machine. A knife-edge is located at the top of the foil; the thickness of the electrode coating is controlled by adjusting those gaps between the knife edge and foil.

The foil which is coated foil is fed directly into a sizeable dying oven to bake the electrode material. The coated foils are then fed into the slitting machine. It would cut the foil into narrow strips suitable for different sizes.

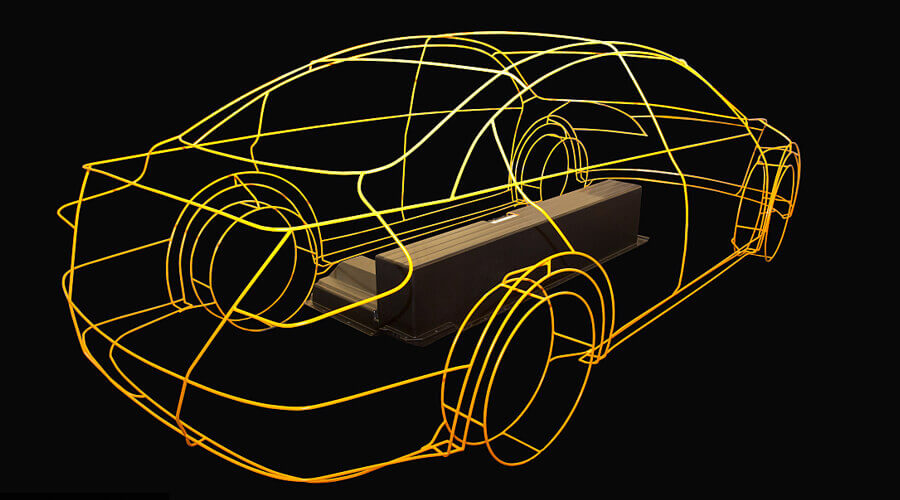

Cell Assembly: In some of the best factories, cell assembly is carried out by highly automated equipment. Some of the factories even have some still small manufactures who use manual assembly methods. The first stage of the assembly process is to build the electrode sub-assembly. They use a separator, which acts as a sandwich between the anode and the cathode. There are two electrode structures and are used depending on the type of cell casing to be used; It is a stacked structure for use in prismatic cells and a spiral wound structure for use in cylindrical cavities.

Formation: After completion of the cell assembly, the batteries are put through at least one precisely controlled charge/ disaster cycle to activate the working material, transforming them into their useable form. The charging process begins with low voltage and then gradually built up. This process is named as formation process. For creating most of the Lithium batteries, they need an SEI as an anode.

Process Control: Those tight tolerances and strict process controls are necessary throughout the process of manufacturing. Contamination, physical damage, and burns on the electrodes are dangerous as they can cause penetration. The separator gives rise to internal short circuits in the cell. And the worst part is there are no protection methods which can prevent or control this.

Support Service: Cleanliness is a part of manufacturing a Lithium battery. It is essential to prevent contamination, and cells are usually made in a cleanroom. They even have controlled access to assembly facilities often via air shower. Besides production test equipment, battery manufacturers should even have a material laboratory equipped to do a complete analysis of the materials.

What do you think about a good lithium-ion battery assembly line?

This part is to connect the electrode structure to the battery terminals together with some safety equipment and inserts the sub-assembly into the can. The can is then sealed with the heating procedure or a laser welding, depending upon the case material, leaving an opening to inject the electrolyte into the box.

Prismatic Cells: These cells are often used for high capacity battery applications as it can optimize the use of space. The design is a stacked electrode structure in which the cathode and anode foils are cut into individual. The electrode plates are stacked alternatively and are kept apart by the separator. Separators are reduced in the same size as the electrodes, and they are applied as a long strip wound within a zig-zag fashion.

During this period, the optimum use of space when used in a battery pack, it’s a disadvantage is that it uses multiple electrode plates which need clamping mechanism. To get connect all the anodes and are the main terminal post. It also has a similar tool for cathodes. This all adds to the complexity and labor content of the cell and consequently which affects the cost. They are many prismatic cells that are made by the more straightforward method of winding the electrodes on a flat mandrel.

Cylindrical Cells

Cylindrical cells, the anode and cathode foils can be cut into two long strips, those are tied on a cylindrical mandrel, together with the separator, which keeps them apart, to form a jelly roll. The best part is the single tab connects all the electrodes to the corresponding terminal. However, the high-power cells may have multiple tabs welded along the edge of the electrode strip and carry the higher currents.

Do you know the manufacturer with an excellent lithium-ion battery assembly line?

Some of the right manufacturer companies who are good with lithium-ion battery assembly line are:

Tata Motors

Suzuki Motors Corporation and Toyota Motor Corporation

Bharat Heavy Electricals Limited

Adani Group

Conclusion:

Lithium-Ion does offer the best options for electrical equipment are easy to assemble. The process used for manufacturing lithium-ion batteries is equaled to those used during production of Nickel Cadmium cells and Nickel Metal Hydride cells only with some key difference those are associated with a higher reactivity of the chemicals used in Lithium cells.

- Prev Article: Zinc-air Battery vs. Lithium-Usage and Differences

- Next Article: Lithium-air Battery Breakthrough-Technology and Characteristics

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News