How to prolong the service life of lithium-ion battery?

Mar 19, 2019 Pageview:888

Lithium-ion batteries work by migrating ions between positive and negative electrodes. In theory, lithium-ion batteries can work all the time under this mechanism. However, with the extension of time, the battery performance is degraded due to the increase in temperature and the aging of the battery due to the charge and discharge cycle. Manufacturers have adopted conservative estimates that most commercial lithium-ion batteries have a cycle life between 300 and 500 cycles.

However, it is not practical to assess the life of a battery by the number of cycles because there may be deep discharges during discharge and there is no clear standard to characterize the concept of the number of cycles. In addition to being characterized by cycle counts, some device manufacturers recommend using a date stamp to indicate when to replace the battery, but this method ignores the environmental conditions at the time of use and is also unreliable. A battery may be retired during the life of the product due to overload or temperature conditions, but most battery packs have a service life that exceeds the specified time.

Battery performance is characterized by battery capacity, which is also an important battery safety indicator. Battery internal resistance and self-discharge can affect battery capacity, but this effect is negligible for determining the ultimate life of a new lithium-ion battery.

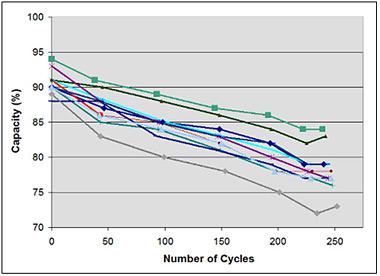

Figure 1 shows the capacity decay of 11 lithium polymer batteries in the Cadex laboratory cycle test. This mobile phone uses a 1500mAh pouch battery, first charged to 4.2V at 1C, and then fully charged at 0.05C. Subsequently, the battery was discharged to 3.0 V at a rate of 1 C, and the cycle was repeated. The expected capacity decay of a lithium-ion battery over a cycle of more than 250 cycles is consistent with the measured capacity decay.

Figure 1: after the cycle of the battery capacity attenuation

The cycle testing of 11 new lithium-ion batteries was performed by the Cadex C7400 battery analysis equipment. The capacity of all battery packs for the first discharge was 88-94% of the initial capacity, and after 250 cycles, it was attenuated to 73-84%. And, these 1500mAh battery packs are used in mobile phones. (Data provided by Cadex)

Although the battery should release 100% of its capacity during the first year of operation, it is usually lower than the given capacity, and the unused battery will cause capacity degradation. And manufacturers tend to over-calibrate their battery capacity because they know that very few consumers will complain. In addition, most mobile phones or tablets only need to use a single battery, instead of requiring multiple battery packs, which also provides a wider acceptable range for battery performance, and some of the poorer batteries are therefore ignored.

As with mechanical equipment used for overload, deep discharge can also cause a reduction in the number of battery cycles. Therefore, shortening the discharge time is advantageous for extending the battery life. In addition, we should avoid completely discharging or charging the battery as much as possible. Incomplete discharge is beneficial for lithium-ion batteries. Lithium-ion batteries have no memory effect and do not require periodic full discharge cycles to extend battery life. However, there are exceptions, such as fuel gauges or smart devices that need to be calibrated regularly.

Table 2 compares the cycles required for lithium-ion batteries to charge and discharge cycles to 70% of capacity reduction. Other variables such as charging voltage, temperature, and load current are the default settings.

Heat or high charging voltage can also make greater burden on the lithium ion battery, 30 ℃ (86 ° F) for most of the lithium ion battery has a higher temperature, more than 4.10 V/cell voltage of high voltage. Will be fully charged battery a long time exposed to high temperatures than lithium ion battery cycles increase pressure. Table 3 represents the capacity loss as a function of temperature.

Most of the lithium ion rechargeable to 4.20 V, when charging the cut-off voltage of 0.1 V, the cycle of the battery life will be doubled. Lithium ion batteries, for example, to 4.2 V, can usually be loop 300-500 times; If charge cut-off voltage to 4.10 V, for life can be extended to 600-1000 - cycle; Set to 4.00 V charging system can achieve 1200-2000 - cycle; For 3.90 V, can reach 2400-4000 - cycle.

However, low charging voltage tends to reduce the capacity of the battery. Typically, charge cut-off voltage for every 70mv, reduce 10%, the total capacity will reduce battery and rises to the cut-off voltage, would get 100% of capacity.

For cycle life, the optimal charging voltage for a Li-Ion battery is 3.92V. Battery experts believe that this threshold eliminates all voltage-related adverse effects, and below this value, it can have other adverse effects on the battery. Table 4 summarizes the battery capacity conditions at different charge levels, all values are estimates.

Mobile phones, laptops, tablets, and digital cameras use lithium ion battery charger charging voltage is set as 4.2 V, this also will provide the biggest capacity, for the longest time, after all, is the first choice for consumers. On the other hand, for the factory, for their part, priority is the battery life, and therefore tend to choose low voltage threshold. For example,specials and electric cars, battery life is higher than the importance of capacity.

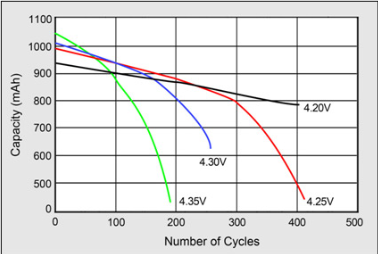

For safety reasons, many lithium-ion battery charging voltages cannot exceed 4.2V (the exception is the high energy density ternary material battery, which has a charging voltage of 4.3V). Although higher voltages will greatly increase the capacity of the battery, high voltages will shorten the life and reduce safety. Figure 5 shows the relationship between the number of cycles and the charging voltage, where the number of cycles is reduced by half at 4.35V.

Figure 5 shows the relationship between the number of cycles and the charging voltage.

Increasing the charging voltage will increase the battery capacity, but will also reduce the cycle life and safety of the battery [from Choi et al. (2002)]

In addition to selecting the optimal voltage threshold for a given condition, lithium-ion batteries should not normally operate at higher voltage limits in order to achieve a longer lifetime. Just like the muscles need to relax after strenuous exercise, after the battery is fully charged, the battery needs to be removed to restore the voltage to a natural level. Although the running charger will automatically stop charging when the battery is fully charged, some chargers will continue to charge when the termination voltage drops to a given value.

The page contains the contents of the machine translation.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News