Which is better for electric vehicles performance, LiFePO4 or ternary lithium-ion?

Feb 15, 2019 Pageview:2487

It is believed that many people have heard that new energy vehicle has two kinds of power battery: ternary lithium battery and LiFePO4 battery. So, what's the difference on the performance between these two different materials? What causes these differences? Due to the change of government subsidies tendentiousness, BYD has achieved mass production in the field of LiFePO4 battery in the past, and turn to the large-scale development of ternary lithium. What's the reason?

The structure and principles of lithium-ion battery

If seen batteries, lithium-ion batteries must know, it looks like our 5th battery is the same as the common, but a little bit big size. We can see from the outside of the battery, the positive and negative, and the shell of the battery. And the structure and working principle of inside the battery is what?

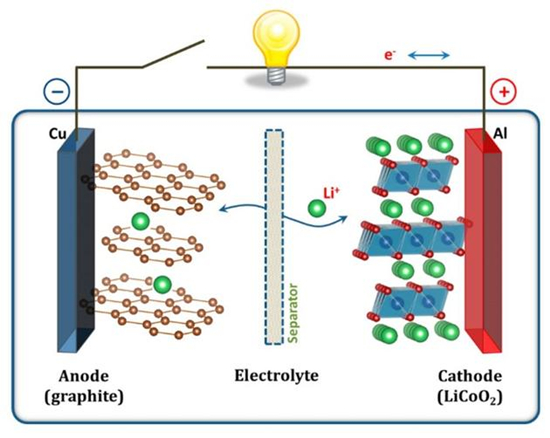

Inside the battery is mainly composed of the positive and negative, electrolyte and diaphragm of four parts, the material is encapsulated in a cylinder of the cylinder. Because there are many tiny holes on the anode material, so can store a large number of electrons. In the process of discharge, the electrons are passed via external circuit, moving to the anode material. When connected to external electric cell, will form to use electrical appliances from the positive to the negative terminal of circuits. This is the basic working principle of the battery.

The basic principle diagram of the charging and discharging lithium-ion batteries

Graphite anode materials is our common. Because the natural graphite has many holes, and good electrical conductivity, it can seize the electronic capacity significantly more than the anode material. So, for the lithium battery, the major bottleneck stuck in the anode material. This is the big battery companies in order to improve the charge of lithium battery (energy density), continuous improvement in performance of the anode material. We often say that the ternary lithium and lithium iron phosphate, refers to is the anode material.

Encapsulated batteries (cylindrical)

In the field of traditional lead-acid battery, the electrolyte is the low cost of dilute sulphuric acid. This is why we sometimes when replacing the car battery, a new battery at the time of first use need to refill a liquid, the liquid electrolyte. Because the main components of the dilute sulphuric acid is water, water under the action of acidic particles can produce electrical conductivity, so you can line inside the battery into the current loop. But due to the conductivity of water is poor, traditional lead-acid battery voltage is less than 2 v, and the lithium battery, we use a single batteries voltage can reach 3 to 4 v, so need to use lithium salt to replace the traditional aqueous electrolyte.

The role of the diaphragm is used to block the electronic, make electronic along the flow path, / but ion can through the diaphragm, such already can make it into a loop, and across the electrodes, won't make short circuit.

Lithium-ion battery charge and discharge principle

Lithium-ion battery can charge and discharge, its essence is to convert electrical energy into chemical energy when charging, during the discharge process of chemical energy into electricity. Simple said is, rechargeable lithium ion from the anode materials by embed the electrolyte in the anode materials; Discharging lithium ion anode materials from embedded through the electrolyte to the anode materials, while electronic through the external circuit, a current for Lithium ion batteries in terms of the performance of the anode materials is crucial, it must have good conductivity, and the compatibility of electrolyte with good, and good stability.

Performance difference between LiFePO4 battery and ternary lithium-ion battery

lithium iron phosphate batteries have higher safety and longer cycle life. Experiments have demonstrated that after 1600 times charging and discharging cycle, lithium iron phosphate battery can still have 80% of the electricity. Not only that, in the process of high-power discharge, lithium iron phosphate battery performance is very stable. This is we often meet with the use of the scene: in a hurry, when accelerating or run high-speed battery need high power discharge, and in the process, voltage stability makes the vehicle has better performance. But the actual capacity of battery in the process of high-power discharge decreased, which is why one of the reasons for the electric vehicle running speed range decreases, and the lithium iron phosphate battery's performance is very outstanding in terms of stability.

Pure electric vehicle battery pack and electric motor assembly

Another advantage of lithium iron phosphate is high safety. Resists high temperature 700-700 degrees, for puncture, impact, short circuit and other extreme conditions will not release oxygen, so not violent burning explosion. This is why byd still more passengers in the bus used in lithium iron phosphate batteries. Because the number of bus passenger, passenger car compared to security requirement is higher, but the weight and volume and less sensitive, so the lithium iron phosphate is a very good choice.

But also has two lithium iron phosphate nots allow to ignore the disadvantages: the first is the relatively low energy density, big volume weight; The second is relatively sensitive to temperature, low temperature environment, power will be significantly lower. Due to the energy density cannot meet the provisions of the state's 150 watts/kg, so not suitable for large-scale application in passenger cars.

With water cooling system and balance control of battery pack assembly

Ternary battery now there are two main technical route, nickel cobalt manganese and cobalt nickel aluminum, with nickel cobalt manganese and among them the most representative three elements combination. It combined with cobalt acid lithium, nickel and acid lithium manganese acid lithium advantages of three kinds of material, in fact is the integration of the three materials together. So, its comprehensive performance is better than a single material, its energy density can be more than 200 watts/kg, so the energy density is the biggest advantage of ternary lithium.

But in contrast to the lithium iron phosphate, the safety of the ternary lithium is poorer, the highest temperature is 250-300 degrees. So, the impact, puncture, easily fires and explosions. So, for the cooling system, as well as the whole battery pack thermal management system requires a higher cost of development and design.

The ternary lithium batteries are high speed to popularize and apply

Due to the national policy guidance in the field of passenger cars, the energy density in a higher position, so each car companies in advance or change the ternary lithium battery. Even before the master the technical advantage of byd lithium iron phosphate, and gradually to transform its models use lithium power battery change into three yuan. These models include: tang, qin dynasty and its potential, and so on. Although now adopting ternary lithium battery teng potential has not been sold, but the news that the next round of the new product will use ternary lithium battery.

Including Japanese manufacturer's ACCORD, CAMRY hybrid, and the latest model for sale are widely used ternary lithium battery. After using the ternary lithium, due to the significant changes of higher energy density, smaller cell volume, lower weight, it makes more practical space for crew compartment or trunk. So, overall, ternary lithium-ion battery has more obvious advantages in the present policy environment.

The page contains the contents of the machine translation.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News