-

Key Takeaways

-

Part 1: What are multi-tab battery cell?+

- 1.1 Key differences between multi-tab and traditional battery designs

- 1.2 Structural innovations in multi-tab battery cells

- 1.3 Applications of multi-tab battery cells in industrial sectors

-

Part 2: Advantages of multi-tab battery cells+

- 2.1 Enhanced performance and power output

- 2.2 Improved thermal management and safety

- 2.3 Reduced internal resistance and energy loss

- 2.4 Prolonged lifespan and durability

-

Part 3: Multi-tab battery cells in comparison to traditional designs+

- 3.1 Efficiency and energy density improvements

- 3.2 Safety advancements in multi-tab technology

- 3.3 Cost-effectiveness and long-term benefits for industrial use

-

FAQ+

- 1. What makes multi-tab battery cells superior to traditional designs?

- 2. How do multi-tab battery cells benefit stacked battery configurations?

- 3. Are multi-tab battery cells cost-effective for industrial use?

Understanding the advantages of multi-tab battery cells in modern lithium-ion batteries

APR 27, 2025 Pageview:15

Multi-tab battery cells represent a significant advancement in battery technology. By incorporating multiple tabs for current collection, these cells minimize energy loss and improve power delivery. Their design optimizes lithium-ion battery performance, ensuring safer operations and extended lifespans. Industries like medical, robotics, and industrial benefit from their reliable energy output and superior thermal management.

Key Takeaways

Multi-tab battery cells save energy by lowering internal resistance. This gives more power and makes batteries last longer.

The new tabless design helps control heat better. It lowers the chance of overheating and keeps devices safer in tough uses.

These cells cost less for industries because they last longer. They also need less fixing, making them a good choice for storing energy.

Part 1: What are multi-tab battery cell?

1.1 Key differences between multi-tab and traditional battery designs

Multi-tab battery cells differ significantly from traditional designs in their approach to current collection. Traditional cells typically rely on a single tab for current flow, which can lead to uneven current distribution and increased resistance. In contrast, multi-tab battery cells incorporate multiple tabs strategically placed across the current collector. This design minimizes energy loss and ensures a more uniform current flow.

The multi-tab design enhances the performance of lithium-ion batteries by reducing internal resistance. Lower resistance translates to improved power output and efficiency, making these battery cells ideal for high-rate batteries used in demanding applications. Additionally, the even current distribution reduces the risk of localized overheating, improving the safety and reliability of the battery.

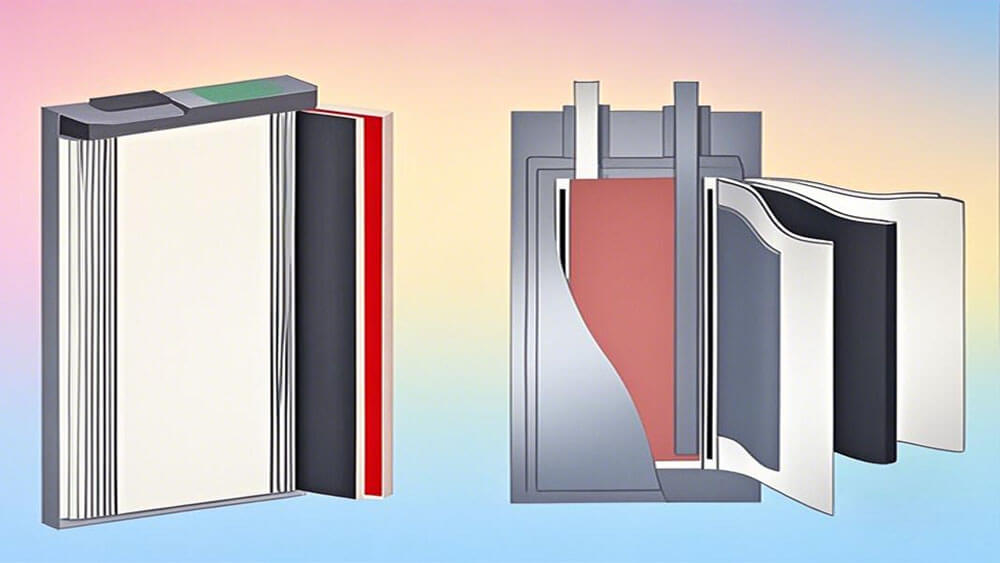

1.2 Structural innovations in multi-tab battery cells

The structural innovations in multi-tab battery cells represent a leap forward in battery technology. One notable advancement is the "tabless" design, where tabs are integrated directly into the current collector foils. This approach eliminates the need for separate tabs, reducing ohmic resistance and enhancing current distribution. As a result, potential losses are minimized, and thermal management is significantly improved.

Engineering studies have demonstrated that integrating multiple tabs into the current collector creates a more uniform current flow. This uniformity is crucial for maintaining consistent performance and preventing hotspots within the battery. Improved heat transfer further enhances the safety and longevity of the cells, making them suitable for applications requiring high reliability, such as medical devices and robotics.

Tip: The tabless design not only boosts performance but also simplifies the manufacturing process, reducing production costs and increasing scalability for industrial applications.

1.3 Applications of multi-tab battery cells in industrial sectors

Multi-tab battery cells have found widespread use across various industrial sectors due to their superior performance and reliability. In the automotive industry, these cells play a critical role in electric vehicles (EVs), where efficient energy transfer and thermal management are essential. The multi-tab design ensures consistent power delivery, enhancing the driving range and overall efficiency of EVs.

In renewable energy systems, multi-tab cells provide reliable electrical connections, ensuring stable energy storage and distribution. Their ability to regulate temperature at connection points makes them ideal for solar and wind energy storage solutions.

In addition to automotive and renewable energy, these cells are increasingly used in medical devices, robotics, and instrumentation devices. Their ability to deliver consistent power and maintain safety under high loads makes them indispensable in these fields. For example, in robotics, multi-tab battery cells ensure uninterrupted operation, even during peak performance demands.

Part 2: Advantages of multi-tab battery cells

2.1 Enhanced performance and power output

Multi-tab battery cells significantly enhance performance and power output by optimizing current distribution. Unlike traditional designs, which rely on a single tab, the multi-tab structure ensures a more uniform flow of current across the entire cell. This uniformity reduces localized resistance, enabling the battery to deliver higher power levels consistently. For industries requiring high-performance energy solutions, this improvement translates to more reliable operations under demanding conditions.

The integration of advanced materials, such as carbon-coated aluminum foils, further boosts energy efficiency. Studies show that these materials can reduce internal resistance by approximately 65%, ensuring minimal energy loss during operation. This improvement is particularly beneficial for applications like handheld devices and instrumentation devices, where consistent power delivery is critical.

Note: The enhanced power output of multi-tab cells makes them ideal for high-rate discharge applications, such as electric vehicles and renewable energy systems.

2.2 Improved thermal management and safety

Thermal management is a critical factor in battery technology, and multi-tab battery cells excel in this area. By distributing current evenly, these battery cells minimize the risk of hotspots, which are a common cause of thermal runaway in traditional designs. This feature enhances safety, especially in applications where batteries operate under high loads, such as industrial machinery and energy storage systems.

These results demonstrate the reliability of multi-tab cells in maintaining thermal stability over extended periods. For industries like renewable energy, where batteries must endure fluctuating temperatures, this feature ensures long-term operational safety and efficiency.

2.3 Reduced internal resistance and energy loss

Reducing internal resistance is a cornerstone of improving battery efficiency, and multi-tab battery cells achieve this through innovative design and material selection. The use of multiple tabs decreases the distance electrons must travel, lowering resistance and minimizing energy loss. This design improvement directly enhances the energy density of the battery, making it more efficient for high-demand applications.

These reductions in resistance not only improve energy efficiency but also contribute to the overall durability of the cells. For applications like NMC Lithium batteries, which offer an energy density range of 160–270 Wh/kg, these advancements ensure optimal performance and extended lifespan.

Tip: Lower internal resistance also reduces heat generation during operation, further enhancing the safety and reliability of multi-tab cells.

2.4 Prolonged lifespan and durability

The durability of multi-tab battery cells sets them apart from traditional designs. By addressing common failure modes, such as corrosion and dielectric decay, these cells achieve a longer operational life. Potting materials, used to protect internal components, enhance reliability by reducing the risk of corrosive failures. Although these materials add weight, their benefits far outweigh the drawbacks in terms of longevity.

For applications like LiFePO4 Lithium batteries, which already boast a cycle life of 2000–5000 cycles, the multi-tab design further extends their usability. This makes them ideal for industrial and energy storage applications, where long-term reliability is paramount. Learn more about industrial applications from Large Power.

Callout: Prolonged lifespan reduces the total cost of ownership, making multi-tab cells a cost-effective solution for businesses.

Part 3: Multi-tab battery cells in comparison to traditional designs

3.1 Efficiency and energy density improvements

Multi-tab battery cells outperform traditional designs in efficiency and energy density. By incorporating multiple tabs, these cells reduce internal resistance, enabling a more uniform current flow. This design minimizes energy loss and enhances overall performance. For lithium-based batteries, such as NMC Lithium batteries, this improvement translates to higher energy densities, ranging from 160–270 Wh/kg, making them ideal for high-demand applications like instrumentation devices and handheld devices.

The advanced materials used in multi-tab technology further boost efficiency. Carbon-coated aluminum foils, for instance, lower resistance by up to 65%, ensuring optimal energy transfer. This improvement is critical for applications requiring consistent power delivery, such as robotics and medical devices. The enhanced energy density also supports longer operational times, reducing the need for frequent recharging.

3.2 Safety advancements in multi-tab technology

Safety remains a cornerstone of multi-tab battery technology. The even current distribution reduces the risk of hotspots, a common issue in traditional designs. This feature significantly lowers the likelihood of thermal runaway, ensuring safer operations in high-stress environments like industrial machinery and energy storage systems.

3.3 Cost-effectiveness and long-term benefits for industrial use

Multi-tab battery cells offer significant cost advantages over traditional designs. Their enhanced durability reduces the frequency of replacements, lowering the total cost of ownership. For example, LiFePO4 Lithium batteries, with a cycle life of 2000–5000 cycles, benefit from the multi-tab design, further extending their lifespan. This makes them a cost-effective choice for industrial applications.

The simplified manufacturing process of multi-tab cells also contributes to cost savings. The integration of tabs into the current collector streamlines production, reducing material waste and labor costs. These efficiencies make multi-tab technology a scalable solution for industries requiring reliable and economical energy storage systems.

Callout: Investing in multi-tab battery cells ensures long-term operational efficiency and cost savings, making them a strategic choice for businesses.

Multi-tab battery cells redefine battery technology by enhancing performance, safety, and battery life. Their innovative design ensures consistent power delivery, superior thermal management, and extended life cycles. These advancements make them indispensable for industrial applications, including robotics, medical devices, and energy storage systems. As lithium-based solutions evolve, multi-tab designs will play a pivotal role in shaping the future of energy storage and power systems.

FAQ

1. What makes multi-tab battery cells superior to traditional designs?

Multi-tab battery cells reduce internal resistance and improve current distribution. This design enhances energy efficiency, safety, and durability, making them ideal for industrial and energy storage applications.

2. How do multi-tab battery cells benefit stacked battery configurations?

Multi-tab cells optimize current flow in stacked battery systems. This reduces energy loss and heat generation, ensuring consistent performance in high-demand applications.

Tip: For professional guidance on stacked battery configurations, visit Large Power.

3. Are multi-tab battery cells cost-effective for industrial use?

Yes, their extended lifespan and reduced maintenance needs lower the total cost of ownership. This makes them a strategic choice for industrial and energy storage solutions.

- Prev Article: no more

- Next Article: Comparing Sodium-ion and Lithium-ion Batteries: Key Advantages and Drawbacks

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News