-

Key Takeaways

-

Part 1: Why Lithium Battery Temperature Management Matters+

- 1.1 Impact on Performance and Efficiency

- 1.2 Safety Risks of Temperature Mismanagement

- 1.3 Effects on Battery Lifespan

-

Part 2: Understanding Lithium Battery Temperature Range+

- 2.1 Operational Temperature Range

- 2.2 Recommended Storage Temperature

- 2.3 Variations for Different Applications

-

Part 3: Effects of Extreme Lithium Battery Temperatures+

- 3.1 High-Temperature Risks

- 3.2 Low-Temperature Risks

- 3.3 Identifying Temperature-Related Damage

-

Part 4: Best Practices for Managing Lithium Battery Temperature+

- 4.1 Passive Cooling Methods

- 4.2 Active Cooling Systems

- 4.3 Using Battery Management Systems (BMS)

- 4.4 User Habits for Temperature Safety

- Actionable Tips for Temperature Management:

-

FAQ+

- What happens if you charge a lithium battery at extreme temperatures?

- Can a lithium battery recover from temperature-related damage?

- How can you monitor lithium battery temperature effectively?

The Ultimate Guide to Lithium Battery Temperature Management

APR 15, 2025 Pageview:14

Managing lithium battery temperature is vital for ensuring safety and maximizing performance. Operating outside the optimal range of 20–35°C can reduce capacity and efficiency. High temperatures may cause overheating or thermal runaway, leading to explosions. Cold temperatures, on the other hand, diminish capacity. Proper temperature monitoring prevents these risks and prolongs a lithium-ion battery’s lifespan.

Key Takeaways

Keep lithium batteries between 15°C and 40°C for best use. This range stops overheating and makes batteries last longer.

Use a Battery Management System (BMS) to check temperatures. It can cool or heat the battery when needed to avoid harm.

Store batteries in a cool, dry spot between 15°C and 25°C. Good storage slows aging and keeps batteries working well.

Part 1: Why Lithium Battery Temperature Management Matters

1.1 Impact on Performance and Efficiency

Temperature plays a critical role in the performance and efficiency of lithium batteries. Operating outside the recommended range can lead to significant issues. For instance:

Low temperatures may cause lithium plating, which permanently reduces capacity and energy delivery efficiency.

High temperatures accelerate chemical reactions, leading to faster aging and potential thermal runaway.

To maintain optimal performance, you should implement effective thermal management strategies. These include active cooling systems and intelligent battery monitoring systems. Such measures help regulate temperature and ensure consistent energy output. Performance metrics like the C-rate and state of charge (SOC) also highlight the importance of temperature control. For example, fast charging generates heat, requiring robust cooling mechanisms to prevent overheating.

Metric | Description |

|---|---|

C-Rate | Influences thermal behavior; fast charging increases heat generation, requiring cooling strategies. |

State of Charge (SOC) | Affects lithium-ion concentration gradients, impacting internal resistance and heat generation. |

1.2 Safety Risks of Temperature Mismanagement

Improper temperature management can compromise safety. Lithium-ion batteries are prone to thermal runaway, a dangerous chain reaction triggered by excessive heat. Internal electrical shorts, often caused by high temperatures, can initiate this process. Additionally, charging batteries below freezing or storing them at full charge in hot environments increases stress and failure risks. Even if a battery appears functional, prior exposure to extreme conditions may make it more susceptible to mechanical damage.

1.3 Effects on Battery Lifespan

Temperature fluctuations significantly impact the lifespan of lithium batteries. Research shows that higher temperatures accelerate degradation. For example, at 55°C, the degradation rate of maximum charge storage is over three times higher than at 25°C. Proper storage and temperature monitoring are essential to mitigate these effects. By maintaining batteries within the recommended range, you can reduce aging and extend their operational life.

Temperature (°C) | Degradation Rate of Maximum Charge Storage (%) | Degradation Rate of Warburg Element Resistance (%) | Degradation Rate of Cell Impedance (%) |

|---|---|---|---|

25 | 4.22 | 49.40 | 33.64 |

55 | 13.24 | 584.07 | 93.29 |

Part 2: Understanding Lithium Battery Temperature Range

2.1 Operational Temperature Range

Lithium batteries operate best within specific temperature requirements to ensure safety and performance. The optimal operating ranges typically fall between 15°C and 35°C (59°F to 95°F). Operating below 0°C (32°F) can damage the electrolyte, while temperatures above 35°C (95°F) may lead to overheating and reduced battery health. Prolonged exposure to temperatures exceeding 60°C (140°F) accelerates aging and increases the risk of thermal runaway.

Temperature Range | Effect on Battery Performance |

|---|---|

Below 0°C (32°F) | Damages electrolyte |

15°C to 35°C (59°F to 95°F) | Optimal performance and lifespan |

Above 35°C (95°F) | Overheating can harm battery health |

Above 60°C (140°F) | Accelerates aging and risk of thermal runaway |

Maintaining batteries within their ideal temperature range ensures consistent energy output and minimizes safety risks. You should monitor environmental conditions closely, especially in extreme climates, to avoid performance degradation.

2.2 Recommended Storage Temperature

For lithium batteries, optimal storage temperature is 15°C to 25°C (59°F to 77°F). This range minimizes chemical degradation and preserves capacity during long-term storage. However, most lithium batteries can tolerate a broader safe storage range of -20°C to 45°C (-4°F to 113°F) if necessary, with critical caveats:

Above 45°C: Accelerates electrolyte decomposition and SEI (Solid Electrolyte Interphase) layer growth, permanently reducing capacity.

Below -20°C: Risks electrolyte freezing (in standard Li-ion cells), damaging internal structures.

For ideal storage, avoid exposing batteries to direct sunlight or freezing temperatures. Consistent storage conditions help maintain capacity and extend lifespan.

2.3 Variations for Different Applications

Different applications impose unique temperature requirements on lithium batteries. Lithium-polymer batteries, for example, perform optimally between 15°C and 40°C. Environmental factors also play a significant role. At -30°C, performance drops sharply, while temperatures above 40°C increase safety risks. Although higher temperatures may temporarily improve performance in single cycles, they accelerate degradation over multiple cycles.

Lithium-polymer batteries: Optimal range of 15–40°C.

Critical temperature changes occur at -30°C and 40°C.

Higher temperatures improve short-term performance but harm long-term reliability.

Understanding these variations allows you to select the right battery type and implement appropriate thermal management strategies for your specific application.

Part 3: Effects of Extreme Lithium Battery Temperatures

3.1 High-Temperature Risks

Exposing lithium batteries to high temperatures can lead to severe consequences. When the operating temperature exceeds 40°C, the cycle life of the battery is halved for every 10°C increase. This rapid degradation occurs because elevated temperatures accelerate chemical reactions within the battery, causing capacity loss and increased impedance. For example, at 85°C, a lithium battery loses 7.5% of its capacity after just 26 cycles, while at 120°C, capacity loss jumps to 22% after 25 cycles.

Thermal runaway is another critical risk. It occurs when excessive heat triggers a chain reaction, leading to uncontrolled temperature increases. Lithium-ion batteries can experience thermal runaway between 60°C and 100°C, while solid-state batteries are more resistant, with thresholds exceeding 200°C. To avoid these risks, you should prioritize safely storing lithium batteries in cool environments and avoid charging at extreme temperatures.

3.2 Low-Temperature Risks

Low temperatures also pose significant challenges for lithium batteries. Ion conduction slows down, leading to polarization and reduced capacity. Charging at low temperatures can cause dendrite formation, which may result in internal short circuits and battery failure. Additionally, electrolyte conductivity decreases, and Li+ diffusion resistance increases, further limiting performance.

The materials within the battery also suffer. Cathode materials experience a drop in discharge voltage and capacity, while anode materials face poor conductivity and high internal resistance. These effects make discharging at extreme temperatures inefficient and potentially damaging. To mitigate these risks, you should focus on safely storing lithium batteries in environments above freezing and avoid discharging at extreme temperatures.

Evidence Type | Description |

|---|---|

Ion Conduction Speed | Slows down at low temperatures, causing polarization and capacity decrease. |

Dendrite Formation | Occurs easily during charging at low temperatures, leading to battery failure. |

Electrolyte Conductivity | High conductivity is crucial for better performance at low temperatures. |

Li+ Diffusion Resistance | Increases sharply at low temperatures, limiting battery performance. |

Cathode Material Performance | Discharge voltage and capacity decrease significantly as temperature drops. |

Anode Material Issues | Poor conductivity and high internal resistance at low temperatures affect performance. |

3.3 Identifying Temperature-Related Damage

Recognizing damage caused by extreme temperatures is essential for maintaining battery health. Inhomogeneous degradation is a common issue, affecting various cell types like pouch, cylindrical, and coin cells. This type of damage often results from inadequate thermal management. For instance, poor cooling methods can triple the degradation rate in high-power pouch cells.

Effective thermal management plays a crucial role in slowing down degradation. Monitoring battery performance indicators, such as capacity retention and impedance, can help you identify early signs of damage. Safely storing lithium batteries and using advanced cooling systems can significantly reduce the risk of temperature-related issues.

Findings | Description |

|---|---|

Inhomogeneous degradation | Occurs in various cell types, including pouch, cylindrical, and coin cells. |

Role of thermal management | Effective thermal management slows down degradation processes. |

Impact of cooling methods | Poor cooling methods can triple the degradation rate in high-power cells. |

Part 4: Best Practices for Managing Lithium Battery Temperature

4.1 Passive Cooling Methods

Passive cooling methods rely on natural heat dissipation to regulate battery temperature. These techniques are cost-effective and require minimal maintenance, making them ideal for many applications. You can implement passive cooling by leveraging materials with high thermal conductivity or designing battery casings that promote airflow.

Key strategies include:

Using heat sinks to absorb and dissipate heat through conduction.

Incorporating phase change materials (PCMs) that stabilize temperature by absorbing heat during phase transitions.

Employing heat spreaders to balance the thermal profile and reduce temperature variations between cells.

Encapsulating cells with thermally conductive potting compounds to enhance heat dissipation.

Passive Cooling Technique | Description | Effectiveness |

|---|---|---|

Heat Sinks | Absorbs heat through conduction and dissipates it into the environment. | Maintains optimal temperature range for cells. |

Phase Change Materials | Absorbs heat during phase transition from solid to liquid. | Stabilizes temperature fluctuations. |

Heat Spreaders | Balances thermal profile and transfers heat efficiently. | Reduces temperature variation between cells. |

Potting Compounds | Encapsulates cells in thermally conductive material. | Enhances heat dissipation within the enclosure. |

By integrating these methods, you can ensure stable battery performance and extend the lifespan of your battery packs.

4.2 Active Cooling Systems

Active cooling systems provide precise temperature control by using external mechanisms to manage heat. These systems are particularly effective in high-performance applications, such as electric vehicles and industrial battery packs. For instance, vehicles equipped with active cooling systems, like Tesla models, experience significantly less range loss in extreme weather compared to those without such systems.

Vehicle Model | Temperature Condition | Range Loss (%) | Cooling System Type |

|---|---|---|---|

Tesla | Extreme Weather | 15-20 | Active Cooling System |

Nissan LEAF | 90°F (32°C) | 22 | No Active Cooling System |

Active cooling often involves circulating coolants, such as ethylene-glycol, through thermal hydraulic systems. These systems are monitored and controlled to maintain optimal operating temperatures, ensuring safety and efficiency.

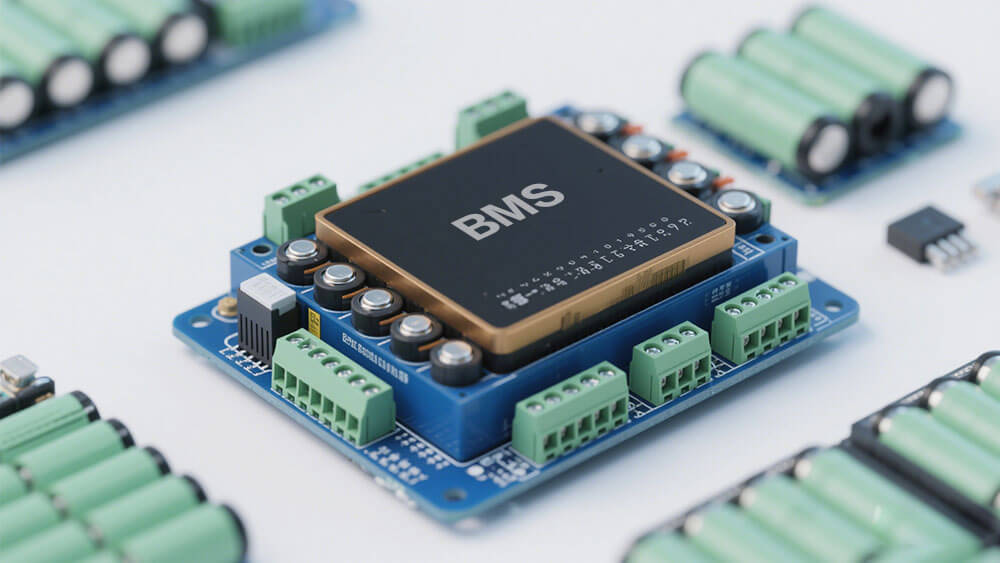

4.3 Using Battery Management Systems (BMS)

A Battery Management System (BMS) is essential for monitoring and regulating lithium battery temperature. It ensures that batteries operate within their safe temperature range, preventing damage caused by overheating or freezing. A BMS can activate heating or cooling mechanisms as needed, maintaining consistent performance.

Benefits of a BMS include:

Preventing lithium plating on the anode during charging at low temperatures.

Reducing efficiency losses caused by temperature increases. A 10°C rise can lower efficiency by up to 20%.

Managing active cooling systems, such as thermal hydraulic setups, to prevent overheating.

By integrating a BMS into your battery packs, you can enhance safety, extend lifespan, and optimize performance.

4.4 User Habits for Temperature Safety

Your habits play a crucial role in maintaining safe battery temperatures. Avoid exposing batteries to extreme heat or cold for prolonged periods. Store them in well-ventilated areas, away from direct sunlight or freezing conditions.

Best practices include:

Charging batteries within the recommended temperature range.

Avoiding rapid charging or discharging in extreme climates.

Regularly inspecting battery packs for signs of overheating or damage.

By adopting these habits, you can minimize risks and ensure the long-term reliability of your lithium batteries.

Maintaining safe lithium battery temperature ranges is essential for safety, performance, and longevity. Operating batteries within 20°C to 35°C ensures optimal efficiency and prevents risks like thermal runaway. Exceeding 130°C can destabilize cells, while temperatures above 150°C may trigger catastrophic chain reactions.

Actionable Tips for Temperature Management:

Monitor temperatures using advanced tools like hybrid machine learning frameworks. These systems predict anomalies and enable proactive maintenance.

Adopt cooling systems to regulate heat. For instance:

Methodology

Description

Real-time Deployment

Facilitates dynamic diagnostics and proactive maintenance interventions.

Hyper-parameter Tuning

Enhances prediction accuracy under varying conditions.

Store batteries properly in environments between 15°C and 25°C to reduce aging.

Prioritizing temperature management safeguards your batteries from overheating or freezing. It also ensures consistent performance, extending their lifespan. By implementing these strategies, you can maximize safety and efficiency while minimizing risks.

FAQ

What happens if you charge a lithium battery at extreme temperatures?

Charging at extreme temperatures can cause lithium plating or thermal runaway. Both issues reduce battery capacity and pose safety risks. Always charge within the recommended range.

Can a lithium battery recover from temperature-related damage?

No, temperature-related damage is usually irreversible. Prolonged exposure to extreme heat or cold permanently degrades capacity and performance. Prevention is the best approach.

How can you monitor lithium battery temperature effectively?

Use a Battery Management System (BMS) or thermal sensors. These tools provide real-time temperature data, ensuring batteries remain within safe operating ranges.

- Prev Article: no more

- Next Article: The Ultimate Guide to IP Ratings for Lithium Battery Durability

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News