How Much Do You Know About Lithium Polymer Battery Structure?

Aug 12, 2019 Pageview:1348

With how much batteries, in general, have gained popularity over the last few decades, engineers and scientists almost never expect regular folks to be clueless about batteries, especially Lithium Polymer Batteries. The good question, however, remains, how much do you know about Lithium Polymer Batteries?

To begin with, do you know that the Lithium Polymer Battery is commonly referred to as LiPo Battery? Well, they are and just as the name implies, Lithium Polymer batteries are designed to function with lithium-ion technology, unlike regular liquid electrolyte used in other battery types, they are also pocket-friendly rechargeable batteries despite the advanced technology employed in its design. LiPo batteries are designed with the weight of the equipment they are to be used with in mind, such as less heavy mobile phones, airplanes, and specific cars.

LiPo batteries aren't the only kinds of lithium-based batteries that have been designed within the industry, LiPo batteries differ from other Lithium batteries because of the nature of their composite electrolyte carrying ions. To help you better understand the LiPo battery, we would review what exactly makes a LiPo battery different from the Lithium-Ion or Li-ion battery using the simplest terms.

The most basic difference is the material used to make the electrolytes used in designing the batteries themselves, Li-ion is designed with liquid electrolytes, LiPo batteries with solid gel-like polymers rather than liquid electrolytes. Cost is more favorable for Li-ion batteries and their energy density is higher. While these factors may make the Li-ion look more appealing, they are no match for the LiPo battery which is safer and weighs far less, are rechargeable and have longer charge usage time.

Now that you know what makes the LiPo battery different, let’s briefly describe the LiPo battery structure. LiPo is the preferred choice in place of other rechargeable batteries such as NiMH or NiCad primarily for its high energy storage density to weight ratios (LiPo batteries while they may weigh more, reserve more energy than almost all other batteries), it's the ability to give consistent voltage output. It can be discharged safely when not in use and can be charged just as fast and finally, LiPo batteries make it possible to adjust voltage, energy output and come in a variety of sizes and shapes.

The LiPo battery is perhaps the most innovative discovery to hit the electric RC, it is being used for helicopters, airplanes and multi-rotor drones and not just mobile devices and they are better off for it. LiPo batteries make it possible to power these devices electronically rather than through fuels.

Complete Guide for Lithium Polymer Battery Structure

· The Pouch Cell and Case

The best place to start learning about the LiPo battery structure is its packaging; the pouch.

The RC LiPo battery cell itself is stored in a protective, malleable plastic casing known as the pouch cell. A pouch cell is designed to safely carry a multi-celled battery, the flat design is created to allow stacking of multiple cells without wasting air spaces as in round celled battery cases. The plastic material makes the battery weigh less. Other Lithium batteries like the Li-Ion 18650 weight at least 20% more than a regular LiPo battery that gives just as much energy.

The cell pouch is protected by a case; hard or soft case. The hard casing is the preferred choice for machines that may be exposed to constant impact and rough usage such as automobile vehicles. They allow for increased battery protection and weigh more than the soft casing.

The hard case also comes with a bullet connector that gives it access to the balanced wiring and main power. The soft case LiPo batteries are better suited for RC air vehicles; they come as a shrink wrap (lightweight) covering the battery cells often with a thin foam protection layer and the balanced wiring and main power are soldered directly to the battery cells to help decrease its weight and stop connection failure.

· The Voltage and Cell Count

Typically, the LiPo battery cell voltage is set at 3.7V for a singular cell, batteries with higher voltage have multiple cells like the 7.4V battery with.

Hence, referred to as a 2S battery pack containing within its two-cell series. The 3S contains three cells within it.

· The Capacity (Power)

The LiPo battery capacity or power is the measurement of how much energy the battery cell is able to hold.

Similar to a car’s fuel tank, the capacity is the energy reserve of the and is measured in milliamp hours or mAh for short. This measurement tells us how energy would be used up when discharged within an hour.

· The Discharge Rating (C-Rating)

The C-Rating is a lot less easy to understand because it does not necessarily have an obvious impact on the efficacy of the LiPo battery as the Capacity or Power does.

We understand this and to help you understand what the C-Rating is, we will describe it simply as how much time a LiPo battery can be safely discharged when not in use. Its measurement is a direct derivative of the battery’s capacity.

· The Internal Resistance

This is how well and how much energy a LiPo battery is able to deliver to the machine it is connected to.

If this number is high, then a lot of energy the battery generates is lost in the form of heat energy, indicating that the battery is inefficient. You should also know that LiPo batteries are designed in a manner that suggests that a lower capacity or C-Rating equal higher internal resistance.

Different manufacturers try to mitigate against this relationship through their designs but it is safer to look out for a low internal resistance value when buying your LiPo battery.

Types of Lithium Polymer Battery Structures

Lithium Polymer batteries differ structurally on different frontiers. They could structurally be different in terms of their shape, thickness, discharge rate, operating temperatures, technology and the component materials used to design them. We would look at these structural differences in detail.

LiPo batteries can come in very many sizes with the square-shaped LiPos being the most common ones and very easily designed and manufactured. We also have batteries that have circular shapes, very much like flat buttons; these circular LiPo batteries have higher energy density and were produced as a replacement for the less efficient button batteries that have much lower rates of discharge.

The other types include the digital-cigarette-like LiPo batteries, they horn a cylindrical shape and fit batteries with cylindrical shapes perfectly. Technological advancements in mobile devices have warranted the design of the curvy LiPo batteries used in devices like smart wristbands and watches. The LiPos used in blue tooth devices and headphones is shaped like the moon. We see that as a technology for gadgets, machines, and tools develop, the structural shapes of LiPos also become less regular.

Another structural difference to consider is the LiPo battery width and thickness; there are standard 2mm~15mm thick LiPo batteries and the 0.4mm~2mm ultra-thin LiPo batteries made to better fit technologically advanced gadgets. LiPo batteries also come at different discharge rates; the standard 0.2 C-Rating with a 2C discharge rate peak and the high discharge batteries used in the latest RC machinery gadgets that need their discharge currents to be much larger.

At low temperature, the LiPo battery works -40C and even lower at -50C suitable for working in cold exposed environments. The normal working temperature and operating rate for a LiPo battery are at -20C~+60C with a charging temperature of 0C~45C range used in regular devices and gadgets. The direct opposite of the low-temperature LiPo batteries are the high-temperature batteries reaching as high as 50C, 60C.

When it comes to LiPo battery component materials and technology cut across the lithium cobalt oxide component type which is the most common type made of pure positive cobalt used commonly for smaller devices, it is good for its life cycle, a stable operating voltage and a rather impressive high energy density. The Nickle-Cobalt-Manganese offers a more balance battery operation than the pure cobalt and costs less. You would find them in solar power appliances and vehicles that run on electricity.

Also, there is the Lithium-Manganese-Oxide Lipo battery commonly found in electrical motors and bikes. It has a lower energy density than the previously mentioned types and costs less as well.

The last LiPo battery structure that is available is the Lithium-Iron-Phosphate or the LiFePO4 made of Lithium, iron, and phosphate. This type of LiPo has a longer cycle life up to 2000 times more than the regular 300 to 500 cycle life. Sadly, voltage and energy density are not as impressive.

What is the Basic Structure of Lithium Polymer Battery?

Generally, the LiPo battery basic structure allows it to make available much more energy than any other category of batteries developed so far within the lithium battery world, they are critically designed for weight-sensitive gadgets, device, and machines such as radio-controlled airplanes and mobile gadgets.

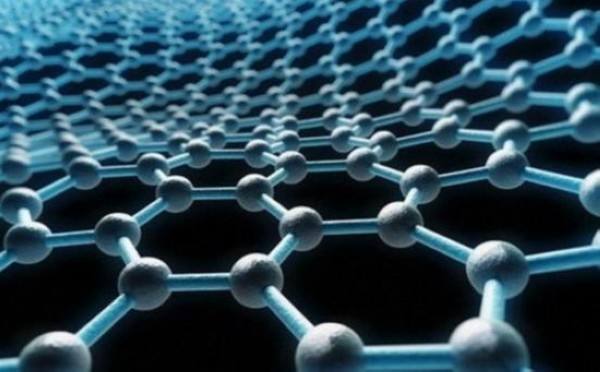

The basic structure comes in either a cylindrical or rectangular shape that comprises of a polyethylene material that can be penetrated easily between the space around the anode and cathode. The anode of the LiPo battery is typically made up of Lithium and CoO2 and aluminum films for the Li-ion and current collectors respectively. The cathode is typically made up of Carbon sheet materials and bronze film for the Li-ion and CoO2 and the current collectors respectively. A LiPo battery is composed of a solution of organic electrolyte.

· Storage and Use

The main component of LiPo is lithium which is an alkali metal that when exposed to water or heat, reacts and combusts.

This happens because extreme usage releases more than enough Oxygen and Lithium atoms through the cathode or anode ends respectively which can cause lithium corrosion or rust, scientifically known as Li2O that sadly increases the internal resistance and cause more energy loss through heat. Use LiPo batteries for longer by storing them safely at room temperature with the voltage safely kept at 3.8V for each cell after each use.

Wrapping It Up

It is important to dispose of bad or faulty LiPo batteries because they are dangerous to have around unused.

Before disposing of, you can personally discharge your LiPo battery and then soak in warm saturated saltwater to shut down the battery completely or simply return to battery recyclers. Lithium batteries are unsafe for our environment when not in use, do well to dispose of appropriately.

- Prev Article: How to know more about 18650 Battery Ratings

- Next Article: How to Restore Lithium-ion Battery Capacity

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News