Lithium Ion Battery Factory-Popularity And Manufacturing Process

Dec 25, 2019 Pageview:1365

As the usage of lithium batteries are increasing day by day. That is why it’s manufacturing process and its popularity should be known to every person.

The methods used to make lithium batteries are very similar to those used to manufacture nickel cadmium cell and nickel metal hydride cells with certain important differences in their higher reactivity which is further explained below in this article.

Who Is The Largest Manufacturer Of lithium battery?

The largest manufacturer of lithium batteries in the world by capacity is LG Chem.

By the end of 2020, LG Chem is preparing to increase its production capacity to 110GWh. In order to meet its growth target, LG Chem needs to grow to a total of 170 GWh in 2024. New factories in China and Poland are under construction, and LG Chem plans to build a second US factory. Further details on LG Chem and its source of raw materials here. Please note that it is critical that Capex is most likely funded from equity or other debt dilution.

Also Panasonic is another largest manufacturer of lithium batteries especially in Japan. Panasonic from Japan is the number 4 battery manufacturer in the world and the number 1 battery supplier from Japan with strong connections to Tesla.

In order to supply Tesla, BMW and Toyota, Panasonic has deals. Given the size of Toyota, the latest partnership between Toyota and Panasonic has great potential.

Panasonic has a JPY 2.23 T (US$ 20.5B) market cap. JPY 122.5B (~US$8.8B) is forecast for 2019 debt. PE is 7.8 in 2019 and PE is 11.1 in 2020. The net profit margin for 2019 is 3.55% and for 2020 it is 2.48%.

How Do You Manufacture lithium ion battery?

The manufacturing process of lithium ion battery I described below;

Assembly of Cell

In the best factories high-automation cell assembly is usually carried out, but many smaller manufacturers still have handling methods.

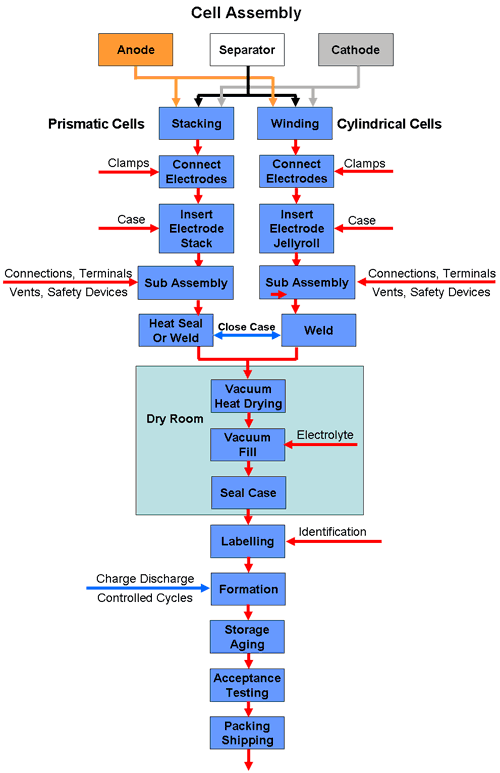

The first step in the assembly process is the creation of a subassembly in which the anode-cathode separator is sandwiched. Based on the cell type used, the structure for use in prism cells is stacked and the framework for the spiral wound used in cylindrical cells is used for two different electrode structures.

Further the cell assembly is classified which is shown in figure 1.

Figure 1

Prismatic cells

Prismatic cells are often used to maximize the use of space in high-capacity battery applications. Both designs use a stacked electrode system where the anode and cathode foils are cut into individual electrode plates that are alternately stacked and separated by the separator. The separator can be cut to the same size as the electrodes, but it is more likely to be placed between opposite electrodes in the stack in a long strip wound in a zig zag pattern.

Cylindrical cells

Of cylindrical cells, the anode and cathode foils are cut into two long strips that are wrapped on a cylindrical mandrel to form a jelly roll (Swiss roll in the UK) together with the separator that holds them apart. Therefore, cylindrical cells have only two strips of electrodes that significantly simplify the construction.

The next step is to connect the electrode structure with any security devices to the terminals and insert this sub-assembly into the can. The can is then sealed, depending on the case content, in a laser welding or heating process, leaving an opening in the can for the injection of the electrolyte.

Manufacturing process

The manufacturing process of lithium ion battery is described below;

The cell must be placed through at least one specific, regulated load / discharge process after the cell assembly is completed to allow the working materials to be transformed into their useful form. The charging process starts with a low voltage, which slowly accumulates, rather than with the usual constant current–constant voltage charging curve. That's what the preparation process is called. It includes the development of the SEI (solid electrical interface) on the anode for most lithium chemical applications. This is a passive layer necessary for the usual use to control the charging process.

For quality analysis and traceability data are collected and reported during creation, on cell output such as capability and impedance. The diffusion of the measurement of output often indicates if the method is regulated. (Pay attention to manufacturers who use it to sort their cells into different output classes for sale with other requirements). Although not the primary objective of development, the process allows a significant percentage of early life cell failures due to manufacturing defects, the so-called "infant mortality," to occur at the plant of the supplier rather than at the premises of the customers.

Command of the operation

Throughout the production process, tight tolerances and strict process controls are important. Contamination, physical damage and burrs on the electrodes are particularly dangerous as they can cause the separator to penetrate, resulting in internal short circuits in the cell, and there are no methods of defense that can avoid or regulate this.

Where Are lithium ion batteries Made?

It's not just a matter of digging up lithium into a battery. Australia, Chile, Argentina, and China are the current major lithium producer countries, with Australia and Chile accounting for around 75% of the total. Such four countries also have the highest lithium reserves.

Not only Australia has took the top spot, but also Chile and China followed this trend. Due to the role of the metal in the lithium ion batteries that drive electric cars, interest in lithium continues to grow and is still growing in the upcoming years for which further researches and work is carried out by the researchers in the field of batteries to make world ecofriendly and green environment.

Furthermore, Chile had by far the largest reserves and manufacturers of lithium ion batteries ( 7.5 million tons ) and the highest annual production (8,800 tones). One of Bolivia's main lithium reserve bases is in the region of Salar de Uyuni also made lithium batteries, which has 5.4 million tons.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News