-

Key Takeaways

-

Part 1: Understanding Batteries in Series and Parallel+

- 1.1 What Are Batteries in Series?

- 1.2 What Are Batteries in Parallel?

- 1.3 Key Differences Between Series and Parallel Installations

-

Part 2: Practical Applications of Series and Parallel Configurations+

- 2.1 Applications of Batteries in Series

- 2.2 Applications of Batteries in Parallel

- 2.3 Hybrid Series-Parallel Configurations and Their Applications

-

Part 3: Charging Batteries in Series and Parallel+

- 3.1 Charging Batteries in Series: Step-by-Step Guide

- 3.2 Charging Batteries in Parallel: Step-by-Step Guide

- 3.3 Tips for Safe and Efficient Charging

-

Part 4: Maintenance and Longevity of Battery Configurations+

- 4.1 Maintaining Batteries in Series

- 4.2 Maintaining Batteries in Parallel

- 4.3 Troubleshooting Common Issues in Series and Parallel Installations

-

FAQ+

- 1. What is the best configuration for Lithium-Ion batteries in industrial applications?

- 2. How do you maintain LiFePO4 batteries in series?

- 3. Can hybrid configurations improve energy storage systems?

Practical Guide to Using Batteries in Series and Parallel

APR 22, 2025 Pageview:7

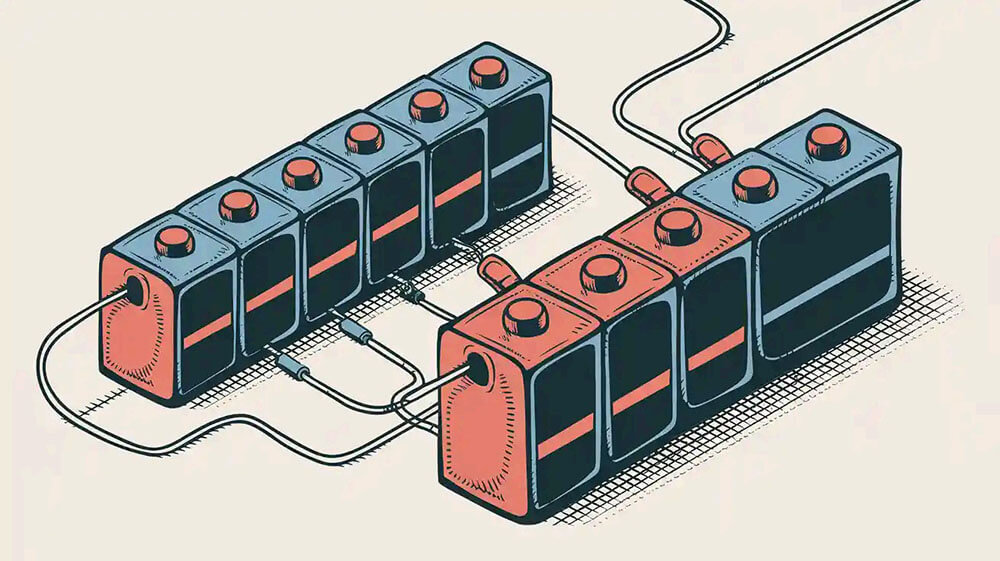

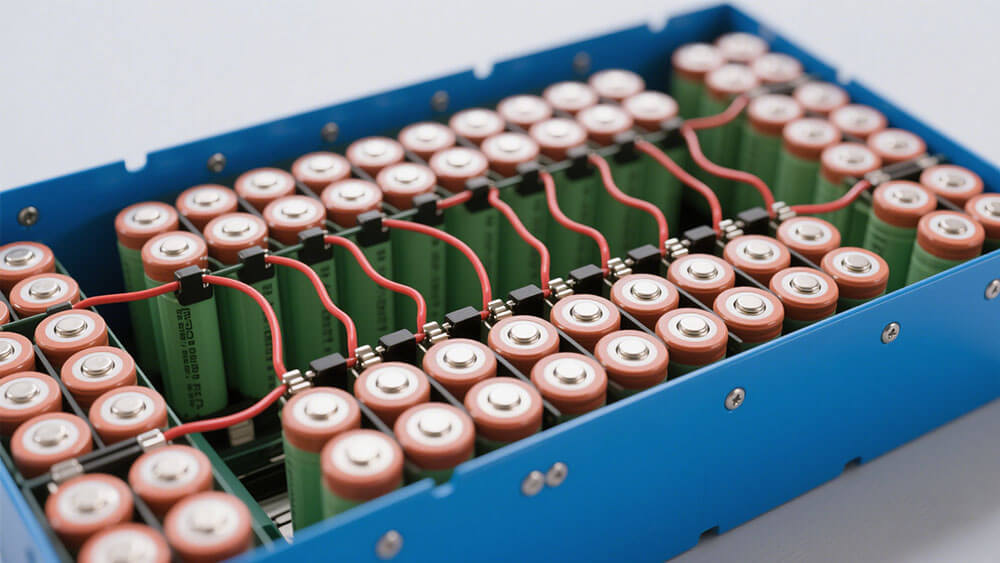

Battery configurations play a critical role in powering modern devices and systems. Whether you connect batteries in series or parallel, the configuration directly affects voltage, capacity, and overall performance. For example, series connections increase voltage, which is vital for high-powered equipment, while parallel setups enhance capacity, allowing devices to operate longer. With the global battery market valued at $50 billion, selecting the proper configuration ensures efficiency and reliability in industrial and commercial applications, from automotive systems to renewable energy storage. Understanding how to optimize a battery in series and parallel can significantly improve your system's performance and durability.

Key Takeaways

Connecting batteries in series raises voltage but keeps capacity the same. This is great for powerful uses like robotics and handheld.

Connecting batteries in parallel boosts capacity, so devices last longer. This works well for surveying equipments and medical devices.

Hybrid setups mix series and parallel connections, giving high voltage and longer use. These are good for advanced systems like unmanned survey vessels.

Part 1: Understanding Batteries in Series and Parallel

1.1 What Are Batteries in Series?

When you connect batteries in series, their voltages add together while the capacity remains the same as a single battery. This configuration is ideal for applications requiring higher voltage levels. For example, two 12V batteries connected in series produce a total of 24V, which is essential for powering electric vehicles or solar power systems.

Series connections ensure uniform current distribution across all batteries. However, they depend on the performance of each battery. If one battery fails, the entire circuit stops functioning. Overcharging or imbalanced discharge can also damage weaker batteries in the series. Despite these challenges, this setup is widely used in devices needing standardized voltage levels.

1.2 What Are Batteries in Parallel?

In a parallel configuration, the total capacity increases by summing the ampere-hour (Ah) ratings of all batteries, while the voltage remains the same as a single battery. For instance, two 12V 100Ah batteries connected in parallel provide 12V with a combined capacity of 200Ah. This setup is perfect for applications requiring extended runtime, such as RVs, boats, or backup power systems.

Parallel connections offer redundancy. If one battery fails, the others continue to supply power. However, differences in battery capacity can lead to uneven charge and discharge rates, potentially degrading performance over time. A study demonstrated that a cell with an internal short circuit in a parallel string experienced accelerated capacity loss, highlighting the importance of using batteries with similar specifications.

1.3 Key Differences Between Series and Parallel Installations

The choice between series and parallel installations depends on your specific needs. The table below summarizes their key differences:

Characteristic | Series Configuration | Parallel Configuration |

|---|---|---|

Voltage | Adds up (e.g., two 12V batteries = 24V) | Stays the same (e.g., two 12V batteries = 12V) |

Capacity | No increase in capacity beyond a single battery | Increases capacity (e.g., two 100Ah batteries = 200Ah) |

Failure Tolerance | If one battery fails, the circuit stops | If one battery fails, others continue to work |

By understanding these differences, you can select the configuration that best suits your requirements. Whether you need higher voltage or extended capacity, series and parallel installations offer versatile solutions for various applications.

Part 2: Practical Applications of Series and Parallel Configurations

2.1 Applications of Batteries in Series

Using batteries in series is essential for applications requiring high voltage. This configuration is commonly seen in industries where devices demand significant energy output. For example, unmanned survey vessels rely on a series connection to achieve the high voltage necessary for efficient motor operation. Similarly, robotics use batteries in series to store and deliver energy at higher voltages, ensuring compatibility with inverters and other equipment.

These demonstrate the versatility of batteries in series for high-voltage applications. Whether you are designing an energy storage system or powering industrial equipment, Large Power ensures reliable performance.

2.2 Applications of Batteries in Parallel

Batteries in parallel are ideal for applications requiring extended runtime and higher capacity. This configuration is widely used in backup power systems, automated guided vehicle(AGV), and boats. By increasing the amp-hour capacity, a parallel connection allows devices to operate for longer periods without recharging.

For instance, lithium batteries in parallel are often used in medical devices, robotics, and industrial equipment. These industries demand consistent power supply and redundancy, which parallel setups provide. If one battery fails, the others continue to function, ensuring uninterrupted operation. However, managing parallel configurations requires careful attention to battery specifications and the use of Battery Management Systems (BMS) to prevent uneven charge and discharge rates.

Key Considerations for Parallel Configurations

A single string of lithium cells is cost-effective and simple to manage.

Parallel strings offer redundancy and hot-swap capabilities, especially in critical applications.

Isolation mechanisms and individual BMS units enhance safety and performance.

By addressing these considerations with Large Power, you can optimize the performance of batteries in parallel for your specific needs.

2.3 Hybrid Series-Parallel Configurations and Their Applications

Combining series and parallel connections creates hybrid configurations that offer the best of both worlds. This setup increases both voltage and capacity, making it suitable for complex systems requiring flexibility and scalability. Hybrid configurations are commonly used in renewable energy systems, such as automated guided vehicle(AGV) and unmanned survey vessels , where energy storage demands vary.

Advantages of Hybrid Configurations

Increased capacity and runtime by connecting multiple cells in parallel.

Reduced risk of total system failure, as a failing cell in a parallel string has minimal impact.

Enhanced design flexibility for custom applications.

For example, hybrid series-parallel configurations are gaining popularity in robotics and survey equipment. These systems require both high voltage and extended runtime, which hybrid setups efficiently provide. However, managing these configurations can be complex, requiring advanced battery management solutions to ensure optimal performance.

By understanding the practical implications of hybrid configurations, you can design systems that meet the demands of modern applications. Whether you are working on energy storage, industrial equipment, or specialized devices, hybrid setups offer a versatile solution.

Part 3: Charging Batteries in Series and Parallel

3.1 Charging Batteries in Series: Step-by-Step Guide

Charging batteries in series requires precision to ensure balanced performance and longevity. When wiring batteries in series, you must use a charger that matches the total voltage of the configuration. For example, three 12V batteries connected in series need a 36V charger. This ensures the entire string charges uniformly without overloading individual cells.

To achieve effective charging strategies for series vs parallel setups, follow these steps:

Step 1: Verify the total voltage of your series configuration.

Step 2: Select a charger designed for the combined voltage. Avoid using chargers with mismatched voltage ratings.

Step 3: Connect the charger to the positive terminal of the first battery and the negative terminal of the last battery in the series.

Step 4: Monitor the charging process to prevent overcharging. Using a multiple-output charger can help maintain balance by connecting each battery individually.

Avoid tapping into individual batteries at lower voltages during charging. This creates an imbalance that standard system voltage charging cannot correct. Proper capacity planning for series and parallel battery wiring ensures consistent performance and prevents premature degradation.

3.2 Charging Batteries in Parallel: Step-by-Step Guide

Charging batteries in parallel focuses on maintaining equal charge distribution across all cells. Unlike series configurations, the voltage remains constant, so you can use a charger rated for the voltage of a single battery. For instance, two 12V batteries in parallel require a 12V charger.

Follow these steps for parallel charging:

Inspect Battery Specifications: Ensure all batteries have similar capacities and charge levels before connecting them.

Connect the Charger: Attach the charger to the positive and negative terminals of the parallel setup.

Monitor Charge Levels: Use a Battery Management System (BMS) to prevent uneven charging and discharging.

Perform Regular Maintenance: Check for signs of overheating or leakage during the charging process.

Parallel configurations offer redundancy, but uneven charge rates can reduce battery longevity in series compared to parallel setups. Using modern chargers and adhering to best practices minimizes risks and enhances efficiency.

3.3 Tips for Safe and Efficient Charging

Safety is paramount when charging batteries. Improper practices can lead to overheating, leakage, or even explosions. To ensure safe and efficient charging, follow these industry best practices:

Establish a charging protocol with scheduled checks to prevent unattended charging.

Use high-frequency chargers to improve battery life and prevent overheating.

Provide protective equipment like gloves and goggles near charging stations.

Maintain an Emergency Response Plan tailored to battery-related incidents.

Regularly inspect chargers and batteries for potential issues.

Training workers on hazards and mitigation strategies further enhances safety. Proper recycling and disposal of spent batteries also comply with environmental regulations. By choosing the right setup for series or parallel configurations and adhering to these guidelines, you can optimize charging efficiency and extend battery life.

Part 4: Maintenance and Longevity of Battery Configurations

4.1 Maintaining Batteries in Series

Proper maintenance of batteries in series ensures consistent performance and extends their lifespan. Regularly inspect the connections between batteries to prevent corrosion or loose terminals. Uneven charging or discharging can damage weaker cells, so use advanced monitoring systems to identify and replace underperforming batteries promptly. These systems analyze real-world performance data, allowing you to implement proactive maintenance strategies.

Combining active balancing with machine learning improves the accuracy of remaining useful life predictions. This approach supports longer battery lifespans by addressing potential issues before they escalate. For example, a study titled Survival Analysis with Machine Learning for Predicting Li-ion Battery Remaining Useful Life highlights how robust feature extraction techniques enhance adaptability and reliability. Integrates robust feature extraction techniques for improved adaptability and reliability, providing actionable insights for dynamic maintenance strategies.

4.2 Maintaining Batteries in Parallel

When wiring batteries in parallel, prioritize maintaining equal charge levels across all battery cells. Uneven charge distribution can lead to overheating or reduced capacity. Regularly check for signs of wear, such as swelling or leakage. Use a Battery Management System (BMS) to monitor and balance the charge levels of each battery. This prevents overcharging and ensures optimal performance.

To maintain longevity, ensure all batteries in the parallel configuration have similar specifications. Batteries with mismatched capacities can degrade faster, reducing the overall efficiency of the system. Advanced monitoring tools can help you detect and address these issues early, minimizing downtime and repair costs.

4.3 Troubleshooting Common Issues in Series and Parallel Installations

Troubleshooting battery configurations requires a systematic approach. For series setups, check for voltage imbalances or failed cells that disrupt the entire circuit. Replace any damaged batteries immediately to restore functionality. In parallel configurations, inspect for uneven charge levels or overheating. A BMS can help you identify and resolve these problems efficiently.

Common issues include loose connections, which can cause power loss or overheating. Tighten all terminals and clean any corrosion to maintain a stable connection. For both configurations, regular testing and monitoring are essential. Advanced tools can provide real-time data, helping you address potential problems before they impact performance.

Tip: Always follow manufacturer guidelines when wiring in parallel or series to avoid safety hazards and ensure optimal performance.

Choosing the right battery configuration depends on your specific requirements. Series setups provide higher voltage, ideal for applications while parallel configurations extend runtime, making them suitable for solar power systems. The table below summarizes their advantages and disadvantages:

Configuration Type | Advantages | Disadvantages |

|---|---|---|

Series | Higher Voltage Output, Simpler Wiring | Uniform Capacity Requirement, Overcharging Risk |

Parallel | Extended Run Time, Redundancy, Scalability | Complexity in Charging, Increased Weight and Space |

For example, connecting four 12V batteries in series results in 48V, perfect for high-voltage needs. In contrast, connecting them in parallel provides 400Ah, ensuring longer operation. Proper wiring, charging, and maintenance are crucial for safety and performance. Optimizing battery designs can also reduce lifecycle costs, especially in industrial and commercial applications.

Tip: Always evaluate your system's voltage and capacity needs before deciding on a configuration.

FAQ

1. What is the best configuration for Lithium-Ion batteries in industrial applications?

For industrial applications, series configurations provide higher voltage, while parallel setups extend runtime. Choose based on your system's voltage and capacity requirements. Learn more from Large Power.

2. How do you maintain LiFePO4 batteries in series?

Regularly inspect connections and monitor charge levels. Use a Battery Management System (BMS) to prevent overcharging or imbalances.

3. Can hybrid configurations improve energy storage systems?

Yes, hybrid setups combine high voltage and extended capacity, making them ideal for energy storage, which enhance flexibility and scalability.

- Prev Article: no more

- Next Article: Lithium and Alkaline Batteries Compared for 2025 Applications

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News