-

1) Overview of Ternary Lithium Battery+

- 1. Lithium Nickel Manganese Cobalt Oxide Density

- 2. Lithium Nickel Manganese Cobalt Oxide Structure

- 3. Chemical Equation of Charge and Discharge

-

2) Advantages and Disadvantages of Ternary Lithium Battery+

- Advantages of Ternary Lithium Battery

- Disadvantages of Ternary Lithium Battery

-

3) Characteristics of Lithium Nickel Cobalt Manganese Oxide (NMC)

-

4) NMC 622 Battery

-

5) NMC 811 Battery

-

6) NMC vs NCA Battery

-

7) LFP vs NMC Battery+

- 1. Energy density: ternary lithium > lithium iron phosphate

- 2. Safety: lithium iron phosphate > ternary lithium

- 3. Low temperature performance: ternary lithium > lithium iron phosphate

- 4. Cycling life: lithium iron phosphate > ternary lithium

- 5. Cost: ternary lithium > lithium iron phosphate

-

8) Performance Comparison of Anode Materials of Mainstream Lithium Ion Battery

Lithium Nickel Manganese Cobalt Oxide (NMC) Battery —LiNiMnCoO2 Manufacturer

Mar 23, 2021 Pageview:9369

1) Overview of Ternary Lithium Battery

Ternary lithium battery refers to lithium battery that uses ternary materials of lithium nickel cobalt manganese oxide (LiNiMnCoO2, NMC) or lithium nickel cobalt aluminate (NCA) as anode material. Ternary means different proportions for different adjustments of nickel salt, cobalt salt and manganese salt as three different components. Lots of batteries have many different proportions of ternary materials.

In terms of shape, ternary lithium batteries can be divided into soft-pack batteries, cylindrical batteries and square hard-shell batteries. Its nominal voltage can reach 3.6-3.8V. It has high energy density, high voltage platform, high tap density, long endurance range, large output power, excellent performance at low temperature, but poor stability at high temperature, and has high cost.

1. Lithium Nickel Manganese Cobalt Oxide Density

Currently, developed ternary anode materials include NMC111, NMC442, NMC532, NMC622, NMC811 and NCA. The performance comparison of these ternary materials is shown in the following table.

| Ternary anode material | NMC111 | NMC523 | NMC622 | NMC811 | NCA |

| 0.1C discharge capacity mAh/g(3.0~4.3V) | 166 | 172 | 181 | 205 | 205 |

| 0.1C mean voltage,V | 3.8 | 3.8 | 3.8 | 3.81 | 3.81 |

| 1C/1C100 weekly capacity retention,%(3.0~4.5V) | 98 | 96 | 92 | 90 | 90 |

| Energy density,Wh /kg | 180 | 200 | 230 | 280 | 280 |

| Safety performance | good | good | medium | bad | bad |

| Cost | most expensive | cheap | expensive | expensive | expensive |

Ternary Material Performance Comparison Tabl

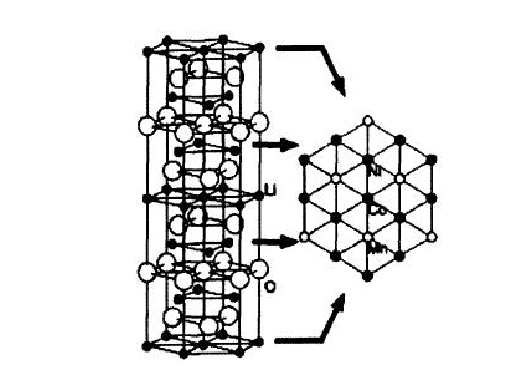

2. Lithium Nickel Manganese Cobalt Oxide Structure

The cambium-like structure of nickel-cobalt-manganese ternary material is composed of hexagonal dense stacking. Its structure and charge - discharge chemical equation are as follows:

Crystal Structure of Nickel Cobalt Manganese Ternary Anode Material

3. Chemical Equation of Charge and Discharge

Discharge: LiNixMnyCozO2→Li1-tNixMnyCozO2+tLi++te

Charge: Li1-tNixMnyCozO2+tLi++te→LiNixMnyCozO2

In nickel-manganese-cobalt ternary material, the incorporation of manganese element can enhance the stability of the material, so that the structure will not collapse due to lithium ion embedding. The addition of nickel can increase the capacity and become a new valence element. Then the ternary anode material system is represented by NMC.

2) Advantages and Disadvantages of Ternary Lithium Battery

Advantages of Ternary Lithium Battery

1. High Voltage Platform

Voltage platform is an important index of battery energy density, which determines the basic efficiency and cost of the battery. Therefore, it is of great significance to the selection of battery materials. The higher the voltage platform, the larger the specific capacity is. With same volume, weight, and even ampere-hour, the higher the voltage platform, the longer the battery life of the ternary material lithium battery has. The voltage platform of the ternary material is significantly higher than that of lithium iron phosphate. With the high line up to 4.2 volts and the discharge platform can be up to 3.6 or 3.7 volts.

2. High Energy Density

High energy density is the biggest advantage of ternary lithium batteries, while the voltage platform is an important indicator of the battery energy density, which determines the basic performance and cost of batteries. The higher the voltage platform, the larger the specific capacity is. Therefore, with same volume, weight, and even the ampere hour, the higher the voltage platform, the longer the battery life of the ternary material lithium battery has.

3. High Tap Density

The tap density refers to the mass per unit volume measured after vibration of the powder in the container under specified conditions. Tap density or volume density (called apparent density in some industries) is defined as the mass of a sample divided by its volume, which includes the sample itself, the pore space of the sample and the volume of the gap between the samples.

Disadvantages of Ternary Lithium Battery

Poor safety: the temperature of the battery increases sharply after charging and discharging with high power, and the oxygen releases after high temperature, which is very easy to burn.

Poor high temperature resistance: under high temperature conditions, the battery performance will be affected.

Short service life: under standard conditions (25℃ working temperature, 0.5C charge and discharge ratio) , the service life of battery is 2000~3000 times.

Poor charge and discharge performance: under the condition of large charge and discharge rate, battery life decreases sharply;

3) Characteristics of Lithium Nickel Cobalt Manganese Oxide (NMC)

| Voltage | Nominal voltage 3.60V, 3.70V; The typical operating range of the battery is 3.0-4.2V/higher |

| Specific energy(capacity) | 150-220Wh/kg |

| Charge (C rate) | 0.7-1C, charge to 4.20V, partially charge to 4.30V; 3h typical charge. Charging current above 1C will shorten battery life. |

| Discharge (C rate) | 1 C. Some cells may exist 2C; Cut-off 2.50 V |

| Cycling life | 1000-2000 (related to discharge depth and temperature) |

| Thermal runaway | Typical value 210°C (410°F). High charge promotes thermal runaway |

| Application | Electric bicycles, medical equipment, electric cars, industry |

4) NMC 622 Battery

NMC622 battery refers to the ternary lithium battery that has 6:2:2 anode material proportion of nickel, cobalt and manganese. NMC622 material is now one of commonly used high nickel NMC materials, and the capacity of the material can be more than 180 mAh/g, which is far higher than that of conventional LiCoO2 materials. However, high Ni content decreases the material thermal stability, impacts the cycling life of material, so the researchers developed a variety of methods to improve NMC622 material cycle stability, such as surface coating, element doping and electrolyte additives, etc.

5) NMC 811 Battery

High nickel NMC811 battery is a ternary lithium battery in which the anode material proportion of nickel cobalt manganese is 8:1:1, and the proportion of nickel is up to 80%. This material is a new type of anode material for lithium ion battery developed in recent years. It has the advantages of high energy density, good cycle stability and reasonable cost.

NMC 811 adopts Mn SO4·H2O, Ni SO4·6H2O and Co SO4·7H2O to prepare the required concentration solution according to the molar ratio of 8:1:1. Put the metal salt solution, ammonia water and caustic soda solution into a 50L continuous stirring reactor at a constant temperature of 60℃, and the required precursor of Ni0.8Co0.1Mn0.1 (OH) 2 is synthesized under certain technological conditions with nitrogen protection. According to the lithium source and precursor molar ratio of 1.05:1, the required raw materials are weighed and mixed evenly in the high-speed mixer at a frequency of 30HZ. The mixtures above are sintered with 80%(v) oxygen under different sintering process conditions, and then produce Li Ni0.8Co0.1Mn0.1O2.

6) NMC vs NCA Battery

According to the composition of anode materials, ternary lithium batteries can be divided into NCA and NMC.

NMC is a anode material composed of three materials of nickel-cobalt-manganese in a certain proportion, while the anode material of NCA is composed of nickel-cobalt-aluminum, each letter corresponding to the chemical initials of the related elements. As you can see, the first two ternary materials are the same, nickel and cobalt, but except for the last one, manganese and aluminum.

NMC refers to LiNixCoyMn1-x-yO2 ternary material, which is the most mainstream ternary material at present and also regarded as the trend of development. In NMC batteries, NMC materials can be divided into NMC111, NMC523, NMC622 and NMC811 according to the content of them, among which the latter number represents the proportion of the materials. With the increase of nickel content, the energy density of the battery increases. The energy density of the type 111 ternary battery is about 2.0kwh /L, and the energy density of the type 622 ternary battery is up to 2.3kwh /L. According to the model and market demand, NMC battery has a good application prospect in 3C or transportation.

NCA refers to ternary material of LiNi1-x-yCoxAlyO2, and the ratio is tend to be 8:1.5:0.5. It was derived from the discovery of lithium nickel oxide (LiNiO2). This battery has a higher capacity and correspondingly lower stability, so some aluminum is added to stabilize the structure. The common molecular formula is LiNi0.8Co0.15Al0.05O2. Strictly speaking, NCA may not be a ternary material, but a modified binary material. Compared with NMC, NCA market is monopolized by Japan Chemical, Toda and Sumitomo Metal. Panasonic and SONY are the main suppliers of NCA batteries, and there are also a few applications in Taiwan. NCA battery has a high energy density ratio. Currently, the high-end ternary battery is mainly NCA. Tesla electric car uses Panasonic 18650 battery, which anode material is NCA ternary material.

At present, NMC and NCA are two ideas to solve the stability problem of LiNiO2 in the market. Mn and Al do not play a capacity role, but play a supporting role and have better stability. High nickel NCA have higher capacity than NCA, but better safety than NMC.

7) LFP vs NMC Battery

From the perspective of battery energy density, low-temperature performance, safety, service life and cost, lithium iron phosphate battery and ternary lithium battery have their own advantages, which lead to the differentiation of the anode material technology route of power lithium battery.

1. Energy density: ternary lithium > lithium iron phosphate

Due to chemical characteristics, lithium iron phosphate battery has low voltage platform and its energy density is about 140Wh/kg. The ternary lithium battery has high voltage and its energy density tends to be 240Wh/kg. In other words, with the same battery weight, the energy density of ternary lithium is 1.7 times that of lithium iron phosphate. There is no doubt that ternary lithium batteries have an advantage in energy density, but the energy density of ternary lithium batteries varies with the different formula (nickel, cobalt, manganese/aluminum in different proportions).

2. Safety: lithium iron phosphate > ternary lithium

The thermal stability of lithium iron phosphate is the best among the current automotive lithium batteries. The electro-thermal peak is over 350℃. When the battery temperature is 500-600℃, its internal chemical components begin to decompose.

Ternary lithium battery has poor thermal stability. It will begin to decompose at about 300℃, so the battery management system has severe requirements for over-temperature protection device and battery management system to protect the safety of the battery. Therefore, lithium iron phosphate is relatively safe at high temperature.

3. Low temperature performance: ternary lithium > lithium iron phosphate

The lower temperature limit of lithium iron phosphate battery is -20℃, and the discharge performance is poor in low temperature environment. The capacity retention rate is about 60 ~ 70% at 0℃, 40 ~ 55% at -10℃, and 20 ~ 40% at -20℃.

The lower temperature limit of ternary lithium battery is -30℃, and its low temperature discharge performance is good. Under the same low temperature condition as lithium iron phosphate battery, its mileage decreases less than 15% in winter, which is significantly higher than that of lithium iron phosphate battery.

4. Cycling life: lithium iron phosphate > ternary lithium

Battery life is the capacity decay of the battery after many times of full charge and discharge. In general, when the battery of an electric vehicle is fully charged, the decay reaches 80% of the original power, which means that the battery should be replaced.

The full charge and discharge cycle of the lithium iron phosphate battery need to be more than 3500 times before the capacity drops to 80% of the original. That is to say, if charge and discharge once a day, lithium iron phosphate batteries still need nearly 10 years to appear obvious decay phenomenon.

And ternary lithium battery has shorter cycling life than lithium iron phosphate battery. More than 2000 times full charge and discharge cycle will make battery begin appear attenuation phenomenon, that is, about 6 years of time. Battery management and vehicle electronic control system can slightly extend a little bit of battery life, but it can only be slightly delayed.

5. Cost: ternary lithium > lithium iron phosphate

lithium iron phosphate battery has advantage in cost. It has no precious metal (nickel and cobalt), so it is relatively cheap to produce.

Ternary lithium battery uses a variety of materials of nickel, cobalt and manganese, and the production of high nickel battery needs a severe process environment, so the current cost is relatively high.

After several years of development, as a key material, lithium, cobalt and other metal began to be lack of resources, especially cobalt. Its price keeps increasing, and the quotation is above 200,000 yuan/ton. The price of a ton of electrolytic nickel is now just over 110,000 yuan. Therefore, battery companies will tend to use NCM 811 to improve the content of nickel and reduce cobalt, which will also decrease the cost.

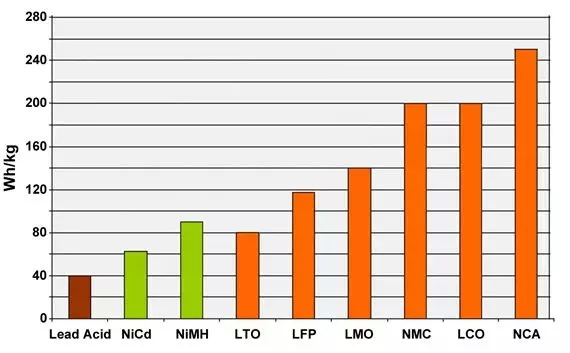

8) Performance Comparison of Anode Materials of Mainstream lithium ion battery

Anode material is one of the key materials that determine the performance of lithium ion batteries, and is also the main source of lithium ion in the current commercial lithium ion batteries. Its performance and price have a great impact on lithium ion batteries. At present, the anode materials developed and applied mainly include lithium cobalt oxide (LCO), lithium manganese oxide (LMO), ternary materials such as lithium nickel cobalt manganese oxide (NMC), lithium nickel cobalt aluminate (NCA), lithium iron phosphate (LFP) and lithium titanate (LTO).

Performance Comparison of Several Commercial Anode Materials

| Item | LCO | LMO | NMC | NCA | LFP | LTO |

| chemical formula | LiCoO2 | LiMn2O4 | LiNiCoMnO2 | LiNiCoAlO2 | LiFePO4 | Li2TiO3 |

| theoretical capacity (mAh/g) | 274 | 148 | 275 | 275 | 170 | 175 |

| actual capacity(mAh/g) | 140 | 120 | 160~220 | 180 | 150 | 160 |

| tap density(g/cm3) | 2.8 | 2.2 | 2.6 | 2.6 | 1 | 1.68 |

| compaction density(g/cm3) | 4.2 | 3 | 3.6 | 3.6 | 2.2 | 2.43 |

| voltage platform(V) | 3.7 | 4 | 3.5 | 3.5 | 3.3 | 2.4 |

| cycling life | better | worse | ordinary | ordinary | good | better |

| transition metal | scarce | abundant | scarce | scarce | abundant | shortage |

| material costs | more expensive | cheap | expensive | expensive | cheap | expensive |

| environmental protection | contain cobalt | non-toxic | contain nickel and cobalt | contain nickel and cobalt | non-toxic | non-toxic |

| safety performance | bad | good | better | better | best | better |

The diagram below compares the specific energies of lead, nickel and lithium systems. Although lithium aluminum (NCA) is the winner by storing more capacity than other systems, it is only suitable for power usage in certain scenarios. Lithium manganate (LMO) and lithium phosphate (LFP) are superior in specific power and thermal stability. Lithium titanate (LTO) may have a lower capacity, but it has the longest life than other batteries and has the best low-temperature performance.

Typical specific energy of lead, nickel and lithium - based batteries

NCA has the highest specific energy; However, lithium manganate and lithium iron phosphate are superior in power and thermal stability. Lithium titanate has the best service life.

- Prev Article: Lithium-Ion Battery Life Cycle Analysis

- Next Article: Build Lithium-Ion Battery Pack Tips

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News