Multi-Stage Battery Charger – Introduction, Circuit, and Car

May 15, 2021 Pageview:922

A battery is one of the most important resources to humans. A battery powers human activities from household accomplishments to their space missions and upcoming technologies. Being such an important component of human life, the need to evolve battery technology for better and improved results is essential to humans.

Because of the ever-increasing demand and need for batteries, over the years humans have developed several types of batteries and their technologies according to their various applications. Every battery has its unique chemical and electrical characteristics and offers a specific output.

Most of the battery’s output efficiency and its operational life depends on its charging. The charging mechanism and the charging technique are such aspects of a battery that can cause most of the harm to the battery and are mostly taken for granted by the users. To reduce the risks of harm inflicted by such practices, the technology of battery charging mechanism has evolved greatly and is still evolving.

The latest form of battery charging technology that works to reduce the consequences of false battery charging involves microprocessors and microelectronic circuits. These types of battery chargers are known as ‘smart chargers’. They make use of the delimited charging procedure that involves performing the charging process in 3 to 4 steps.

Multi-Stage Battery Charger Circuit

Multi-stage battery chargers are of different types depending on the type of battery that is the subject. Some of them may involve high-capacity electronic components, whereas, some of them will be involving components of micro ratings.

Whatever battery that you’re considering, to design a multi-stage battery charger for it you need to know its absorption voltage and the float voltage. Based on the value of these two voltages, you will decide to control the values of voltage for controlling using a potentiometer or a microcontroller.

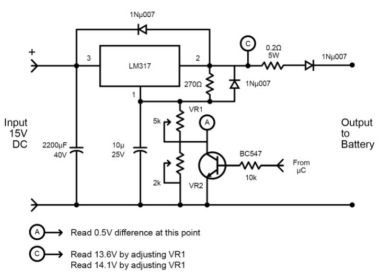

The easiest way to control the voltage is to make use of a voltage regulator IC. ICs are smart components and they are designed to specifically do the job of regulation for whatever voltage level they are designed for. The most common voltage regular ICs that you can use for designing a basic multi-stage battery charger circuit are LM317, LM338, and LM350.

After deciding on the type of voltage regulator IC, the next step is to provide a current limiter on the input pin of the voltage regulator IC. For this purpose, it is the best practice to deploy a 5k Ohm or 2k Ohm variable resistor (potentiometer). To limit the flow of current in an opposite direction diodes are used along with a 0.2 ohms resistor that acts as a current limiting resistor. To get a practical understanding of the multi-stage battery charger circuit, follow the figure provided below:

Multi-Stage Battery Charger Car

Car batteries get discharged like every other battery. Rather, it wouldn’t be wrong to say that car batteries get discharged more as compared to other batteries. Several reasons for this involve malfunction of the car features and human errors. However, when discharged, you don’t have to worry about getting a brand new battery for the car. Car batteries can be easily recharged using car battery chargers.

To simplify this problem of car batteries getting discharged and then getting them recharged, there are multi-stage car battery chargers available in the market (smart chargers). These chargers not only protect your car’s battery against malfunctions but also helps to increase the life of your car batteries by improving the battery charging process.

Multi-stage battery chargers for cars work on a multi-stage cycle that involves the analysis, charging, protection, and repair of the car’s battery. Multi-stage chargers don’t just fill up the car batteries with charge, rather, they analyze the situation of the car’s battery and then opt for a suitable charging mechanism depending on it. Multi-stage car battery chargers may be expensive in the case of some brands but it for sure saves you a great amount of money that you may be spending on dead batteries otherwise. Therefore, these chargers are a good investment to have an increased lifespan and efficiency of the battery.

Smart Multi-Stage Battery Charger

Smart multi-stage battery chargers are called ‘smart’ because of their exclusive three-stage process. These stages are designed to protect the battery from harm, increase its efficiency, and achieve maximum power. Following are the three stages that form the basis of a smart multi-stage battery charger, no matter its application:

1.Bulk Stage

In the bulk stage, the charger fills up 80% of the charge capacity of the battery directly as any normal charger would. The only limitation that applies in this stage is the charging capacity of the charger – how much current can the charge handle at once? In the case of solar-powered multi-stage battery chargers, the only limitation is the visibility of the sun.

2.Absorption Stage

With the increase in charge in the battery, the voltage of the battery also increases. After a while, the voltage of the battery reaches the absorption voltage value. When this value is achieved, the charger shifts to the absorption mode, and the output charging voltage of the charger becomes equal to the absorb voltage. This is also known as the constant charging voltage and this value of voltage is different for each battery. The control of the absorption stage lies in the hands of the charging current that drops after a certain point. But this value of current is difficult to monitor and control, therefore, the control of the absorption stage is given to timespan. The stage goes on for 2 to 5 hours and is then switched off. The time depends on the battery and the values set by the charger manufacturer.

3.Float Stage

After the absorption stage ends, the battery is almost charged but there is very limited space left in the battery storage. To fill up this space, a very critical charge mechanism is required that does not overcharge the battery as it causes harm. To help with this issue, multi-stage chargers make use of the float stage where a constant low-level voltage is used to charge the remaining battery. This is also known as ‘trickle charging.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News