-

Key Takeaways

-

Part 1: What Happens If a Lithium Battery Gets Wet or Submerged in Water+

- 1.1 Chemical Reactions Between Water and Lithium Battery Components

- 1.2 Risks of Short Circuits, Heat Generation, and Gas Release

- 1.3 Potential for Fire, Explosion, and Long-Term Damage

-

Part 2: Freshwater vs. Saltwater Exposure for Lithium Batteries+

- 2.1 How Freshwater Affects Lithium-Ion Batteries

- 2.2 Impact of Saltwater on Lithium Batteries and Corrosion Risks

- 2.3 Why Saltwater Increases the Risk of Fire and Electrolyte Degradation

-

Part 3: Safety Measures for Lithium Battery Packs in Industrial Applications+

- 3.1 Waterproofing and Protective Enclosures for Lithium Batteries

- 3.2 Proper Storage and Handling Practices for Industrial Use

- 3.3 Regular Maintenance and Inspection to Prevent Water Damage

-

Part 4: Steps to Take If a Lithium Battery Gets Wet+

- 4.1 Immediate Actions to Minimize Risks

- 4.2 Safe Disposal of Water-Damaged Lithium Batteries

- 4.3 When to Consult Professionals for Battery Recovery or Replacement

-

FAQ+

- 1. What should you do if a lithium battery gets wet?

- 2. Can lithium batteries be waterproofed for industrial use?

- 3. Why is saltwater more dangerous for lithium batteries than freshwater?

Are Lithium Batteries Safe When Exposed to Water

APR 18, 2025 Pageview:33

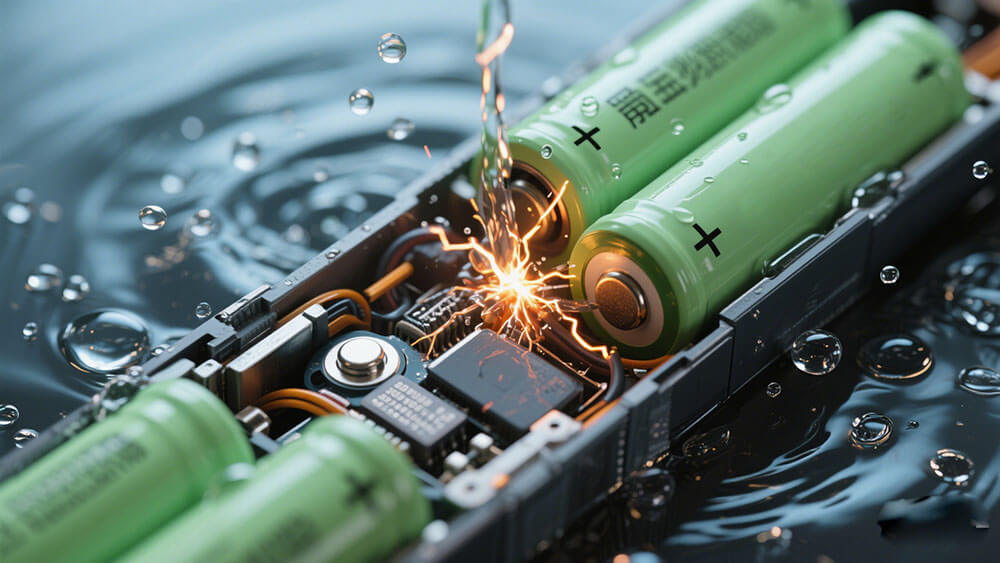

Lithium batteries react dangerously when exposed to water, leading to safety concerns in industrial applications. Water and lithium battery interactions can trigger chemical fires, short circuits, and fire risks. For example, the Hetao Plain in China reported lithium concentrations in groundwater as high as 1790 µg/L, posing a 37.4% non-carcinogenic risk. These risks highlight the importance of implementing robust safety measures to prevent potential disasters.

Key Takeaways

Lithium batteries can be dangerous when they touch water. This can cause fires or short circuits. Keep them dry to stay safe.

Saltwater is more harmful than freshwater because it causes rust. Use waterproof covers to keep batteries safe in workplaces.

Checking and taking care of batteries is very important. Look for water damage and throw away damaged batteries the right way.

Part 1: What Happens If a Lithium Battery Gets Wet or Submerged in Water

1.1 Chemical Reactions Between Water and Lithium Battery Components

When lithium batteries come into contact with water, their chemistry reacts aggressively. Water ingress initiates exothermic reactions, causing a rapid temperature increase. Lithium, being highly reactive, interacts with moisture to produce lithium hydroxide and hydrogen gas. This gas, when mixed with air, forms an explosive combination. The breakdown of lithium compounds further exacerbates the situation, releasing heat and smoke.

A study highlights that water exposure accelerates the decomposition of LiPF6 in lithium-ion batteries, leading to the production of toxic gases like HF. These reactions not only compromise the battery's integrity but also pose significant safety risks in industrial environments. For industries like medical devices, robotics, and infrastructure, understanding these reactions is critical to ensuring operational safety.

1.2 Risks of Short Circuits, Heat Generation, and Gas Release

Water contact with lithium-ion batteries often results in short circuits. When water breaches the battery casing, it disrupts the internal circuitry, causing uncontrolled discharge. This leads to excessive heat generation, a precursor to thermal runaway. The heat, combined with the release of flammable gases like hydrogen and chlorine, significantly increases the risk of explosions.

Case studies reveal that localized high temperatures within the battery can accelerate lithium deposition, further heightening the chances of internal short circuits. For industrial applications, such as energy storage systems or transportation infrastructure, these risks necessitate robust waterproofing measures.

1.3 Potential for Fire, Explosion, and Long-Term Damage

Exploring the risk of lithium batteries exploding due to water exposure reveals alarming outcomes. The combination of heat, flammable gases, and combustible materials within the battery can lead to uncontrollable fires. Water exposure not only triggers immediate hazards like explosions but also causes long-term damage to the battery's chemistry.

Statistics show that water-induced exothermic reactions significantly elevate the temperature, increasing the likelihood of fires. For industries relying on lithium battery packs, such as robotics or medical devices, these risks underline the importance of regular maintenance and protective enclosures.

For custom lithium battery solutions tailored to your industrial needs, visit Large Power's consultation page.

Part 2: Freshwater vs. Saltwater Exposure for Lithium Batteries

2.1 How Freshwater Affects Lithium-Ion Batteries

Freshwater exposure can compromise the performance and safety of lithium-ion batteries. When water enters the battery casing, it interacts with the internal components, leading to chemical reactions that degrade the battery's structure. This degradation can result in reduced capacity, increased internal resistance, and potential safety hazards. For industries relying on lithium-ion batteries, such as medical devices or robotics, even minor water exposure can disrupt operations and lead to costly replacements.

The impact of lithium extraction on freshwater resources further highlights the importance of careful handling. Mining operations divert significant amounts of freshwater, affecting local ecosystems and communities. For instance, lithium mining in Chile has disrupted habitats, threatening species like flamingos. This underscores the need for sustainable practices in lithium battery production and usage.

2.2 Impact of Saltwater on Lithium Batteries and Corrosion Risks

Saltwater poses a greater threat to lithium batteries compared to freshwater. Its high conductivity accelerates corrosion when it contacts the battery's metal terminals. This corrosion can lead to electric arcing, excessive heat generation, and material degradation. Over time, saltwater exposure creates solid shorting bridges within the battery, increasing the risk of delayed thermal runaway.

For industrial applications, such as energy storage systems or transportation infrastructure, saltwater exposure can cause long-term damage. The combination of corrosion and heat generation not only reduces the battery's lifespan but also increases the likelihood of fires. Implementing protective measures, such as waterproof enclosures, is essential to mitigate these risks.

2.3 Why Saltwater Increases the Risk of Fire and Electrolyte Degradation

Saltwater exposure significantly raises the risk of fire in lithium batteries. The interaction between saltwater and the battery's electrolyte produces hydrogen and oxygen gases. These gases, combined with the heat generated by corrosion, create a highly flammable environment. Additionally, saltwater accelerates the degradation of the battery's electrolyte, further compromising its safety and performance.

Industries using lithium battery packs, such as robotics or medical devices, must prioritize safety measures to prevent such incidents. Regular maintenance and inspections can help identify potential vulnerabilities and reduce the risks associated with saltwater exposure.

Part 3: Safety Measures for lithium battery packs in Industrial Applications

3.1 Waterproofing and Protective Enclosures for Lithium Batteries

Waterproofing batteries is essential for ensuring lithium battery safety in industrial environments. Protective enclosures with high IP ratings, such as IP65 or IP67, provide effective water resistance by preventing water ingress. These enclosures shield lithium-ion batteries from water exposure, reducing the risks of short circuits and thermal runaway. Industries like robotics and medical devices often rely on such measures to maintain operational safety. Learn more about robotics applications here.

Hazard Mitigation Analysis (HMA) highlights the importance of explosion control and thermal runaway protection. Certified battery management systems and deflagration venting mechanisms further enhance safety. For large-scale applications, such as energy storage systems, maintaining a permanent water supply for fire suppression is recommended. These measures ensure that lithium batteries remain safe even in challenging conditions.

3.2 Proper Storage and Handling Practices for Industrial Use

Proper storage and handling practices significantly improve lithium battery safety. Independent warehouses equipped with temperature and humidity controls prevent moisture-related damage. Maintaining storage temperatures between -20°C and 35°C minimizes risks like rust and leaks. For long-term storage, keeping lithium-ion batteries at 10°C to 30°C and performing charge/discharge cycles every three months preserves their health.

Follow these best practices:

Store batteries in well-ventilated areas to prevent gas accumulation.

Avoid high-temperature environments and combustible materials.

Cover discarded batteries with insulating paper to prevent short circuits.

These steps are critical for industries like infrastructure and transportation, where battery reliability directly impacts performance. Explore infrastructure solutions here.

3.3 Regular Maintenance and Inspection to Prevent Water Damage

Routine maintenance ensures lithium batteries remain safe and functional. Inspect batteries periodically for signs of water exposure, such as leaks or corrosion. Devices with hermetic seals and reinforced casings offer enhanced water resistance. Selecting batteries with high IP ratings ensures adequate protection against moisture.

If a battery shows signs of water damage, isolate it immediately to prevent further risks. Regular inspections also help identify vulnerabilities early, reducing the likelihood of failures in critical applications like medical devices or industrial systems. For custom solutions tailored to your needs, visit Large Power's consultation page.

Part 4: Steps to Take If a Lithium Battery Gets Wet

4.1 Immediate Actions to Minimize Risks

When a lithium battery is exposed to water, taking immediate steps is crucial to minimize risks. Follow these actions to ensure safety:

Do not attempt to recharge the battery if it has been submerged in water.

If the battery is sitting in water, remove it carefully and avoid any contact with its terminals.

For minimal water exposure, dry the battery thoroughly before considering recharging. However, prioritize keeping the battery in a dry environment.

If the battery shows signs of overheating, hissing, or bulging, move it away from flammable materials. Place it in a non-conductive container, such as a sand-filled metal box, to prevent further damage.

Leaking batteries should only be handled by trained personnel equipped with proper personal protective equipment (PPE).

These steps are essential for industries like medical devices, robotics, and infrastructure, where lithium battery safety directly impacts operational reliability.

4.2 Safe Disposal of Water-Damaged Lithium Batteries

Proper disposal of water-damaged lithium batteries is critical for environmental safety and compliance with regulations. Recycling these batteries reduces fire risks and ensures hazardous materials are handled correctly. Follow these guidelines:

Remove the battery from the device and cover its terminals with insulating tape to prevent short circuits.

Do not dispose of lithium batteries with regular trash.

Take small batteries to designated recycling centers, such as electronic stores or hazardous waste facilities.

For leaking or burned batteries, contact a recycling professional for guidance on packaging and shipment.

Follow local regulations, such as those outlined by the U.S. Department of Transportation, for shipping damaged batteries.

By adhering to these practices, industries can mitigate risks and contribute to sustainable battery management.

4.3 When to Consult Professionals for Battery Recovery or Replacement

In some cases, consulting professionals is the safest option for handling water-damaged lithium batteries. Seek expert assistance if:

The battery exhibits severe damage, such as melting, burning, or extensive corrosion.

You are unsure about the extent of water exposure or the battery's condition.

The battery is part of a critical system, such as medical equipment or industrial machinery, where failure could lead to significant consequences.

Professionals can assess the battery's condition, recommend recovery options, or provide replacements tailored to your specific needs. For custom lithium battery solutions, visit Large Power's consultation page.

Water exposure poses significant risks to lithium batteries, including chemical reactions, short circuits, and fires. Saltwater amplifies these dangers due to its conductivity and corrosive properties. Industries such as medical devices, robotics, and infrastructure must prioritize safety measures like waterproofing and regular inspections to mitigate these risks. Research shows that 4% of electric vehicle fires result from water exposure, emphasizing the importance of proactive handling.

FAQ

1. What should you do if a lithium battery gets wet?

Immediately remove the battery from water. Avoid recharging it. Place it in a non-conductive container and consult professionals from Large Power for further evaluation or disposal.

2. Can lithium batteries be waterproofed for industrial use?

Yes, you can use protective enclosures with high IP ratings (e.g., IP65 or IP67). These enclosures prevent water ingress and ensure safe operation in industrial environments. For tailored lithium battery solutions, visit Large Power's consultation page.

3. Why is saltwater more dangerous for lithium batteries than freshwater?

Saltwater's high conductivity accelerates corrosion and heat generation. This increases the risk of short circuits, thermal runaway, and fires, making it more hazardous than freshwater.

- Prev Article: no more

- Next Article: FCC Certification Requirements for Lithium Batteries Simplified

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News