-

Key Takeaways

-

Part 1: Hygiene Standards and Safety Guidelines for Lithium Batteries+

- 1.1 Hygiene Standards for Lithium Battery Design

- 1.2 Define Medical Application Requirements

-

Part 2: Core Dimensions of Safe Handling Medical Standards+

- 2.1 Material Selection for Biocompatibility and Safety

- 2.2 Sterilization and Contamination Prevention in Design

- 2.3 Safety & Reliability Engineering

- 2.4 Chemical Compatibility in Medical Environments

-

FAQ+

- 1. What are the key hygiene standards lithium battery manufacturers must follow in 2025?

- 2. How can you prevent thermal runaway incidents in medical lithium batteries?

How to Design Lithium Battery of Medical Standards

APR 16, 2025 Pageview:56

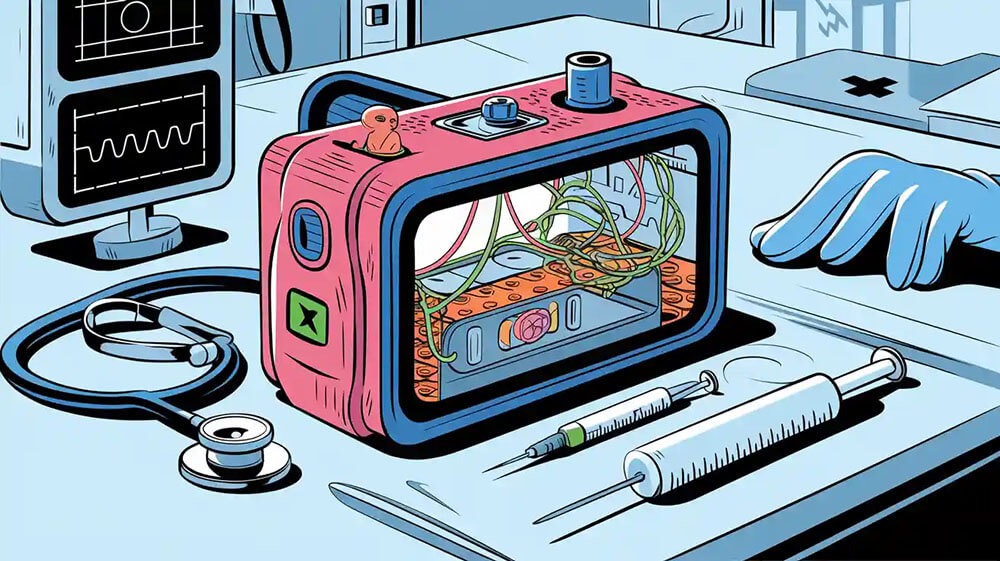

Designing a lithium battery for medical use requires precision and adherence to hygiene standards lithium battery production demands. You must prioritize safety and reliability when creating these batteries, as medical environments require strict compliance with updated standards. Lithium-ion technology offers high efficiency, but you need to ensure it meets contamination prevention requirements. By focusing on quality materials and advanced engineering, you can create batteries that not only perform well but also align with the rigorous protocols of the medical field.

Key Takeaways

Make lithium batteries in clean spaces to keep them safe. Use special ISO-approved rooms to stop dirt or germs.

Use smart systems to check important battery details. This lowers the chance of overheating and keeps them safer.

Test batteries carefully to follow safety rules. Testing finds weak spots and makes batteries work better.

Part 1: Hygiene Standards and Safety Guidelines for Lithium Batteries

1.1 Hygiene Standards for Lithium Battery Design

Lithium battery hygiene standards are technical specifications established to ensure the safe use of batteries in medical, food processing, laboratory, and other environments with stringent requirements for cleanliness, antimicrobial properties, and chemical resistance. These standards focus on eliminating contamination risks, withstanding frequent disinfection/sterilization, and meeting biocompatibility requirements through comprehensive control of materials, design, production, and testing.

Dr. Emily Carter (FDA Medical Device Reviewer) states:

"Solid-state electrolytes like LiPON are pivotal for implantables, eliminating leakage risks and ensuring long-term stability under sterilization."

1.2 Define Medical Application Requirements

Implantable devices (e.g., pacemakers, neurostimulators): Requires long-term biocompatibility and hermetic sealing.

External medical equipment (e.g., infusion pumps, portable monitors): Focus on sterilization resistance and safety.

Surgical robots/AGVs: High energy density, fast charging, and resistance to frequent disinfection.

Key Requirements:

Compliance with ISO 13485 (Medical Devices Quality Management) and ISO 10993 (Biocompatibility).

Tolerance to sterilization methods: autoclaving (121°C), ethylene oxide (EtO), or hydrogen peroxide plasma.

Leak-proof design to prevent electrolyte exposure in sterile environments.

By following advise from Large Power, you ensure compliance with industry standards and enhance the reliability of lithium-ion batteries in medical devices.

Part 2: Core Dimensions of Safe Handling Medical Standards

2.1 Material Selection for Biocompatibility and Safety

Electrodes & Electrolytes

Cathode:

LiFePO4: Cobalt-free, low toxicity, stable thermal behavior (safer for implants).

Avoid Ni/Co-rich cathodes (e.g., NCM, NCA) due to heavy metal leakage risks.

Anode:

Lithium Titanate (LTO): Zero lithium plating risk, wide temperature tolerance (-30°C to 60°C).

Avoid silicon anodes (high volume expansion risks).

Electrolyte:

Solid-state electrolytes (e.g., LLZO, LiPON): Eliminate liquid leakage risks.

For liquid electrolytes: Use fluorinated solvents (e.g., FEC) with low volatility and HF scavengers (e.g., LiBOB).

Housing & Encapsulation

Implantable Devices:

Titanium (Ti-6Al-4V) or 316L stainless steel (ISO 10993-certified).

Laser welding for hermetic sealing (helium leak rate<1×10⁻⁸ cc/sec).

External Devices:

Medical-grade plastics (e.g., PEEK, Ultem®) with autoclave resistance.

Antimicrobial coatings (e.g., silver-ion embedded polymers).

Separators & Safety Components

Ceramic-coated separators (e.g., Al₂O₃) for thermal stability.

Current Interrupt Device (CID) and PTC thermistors to prevent thermal runaway.

316L stainless steel and PEEK are listed in FDA’s Device Material Compatibility Database.

Biocompatibility Testing and Certification

Follow ISO 10993 series for biological evaluation:

Cytotoxicity (ISO 10993-5): Extracts tested on L929 cells; cell viability >70%.

Sensitization & Irritation (ISO 10993-10): Guinea pig maximization test for implants.

Systemic Toxicity (ISO 10993-11): Acute and subchronic toxicity studies.

Chemical Characterization (ISO 10993-18): ICP-MS/HPLC analysis of leachables (e.g., Ni, Co ions<0.1 μg/cm²/day).

2.2 Sterilization and Contamination Prevention in Design

Sterilization and contamination prevention are non-negotiable in hygiene standards lithium battery design. You must incorporate features that allow batteries to withstand sterilization processes like autoclaving or chemical treatments. These processes eliminate microbial contamination, ensuring compliance with hygiene standards.

Medical devices undergo rigorous sterilization. Uses Parylene-coated batteries in endoscopes, reducing VOC emissions by 30%. Ensure battery components withstand:

Sterilization Method | Test Conditions | Pass Criteria |

|---|---|---|

Autoclaving | 121°C, 20 min, 50 cycles | Capacity loss ≤5%; housing deformation<0.5%. |

Ethylene Oxide (EtO) | 55°C, 60% RH, 6 hours | Gas permeability<0.1 ppm; functional integrity. |

Gamma Radiation | 25-50 kGy dose | Polymer elongation at break ≥80% retention. |

Hydrogen Peroxide Plasma | VHP sterilization, 10 cycles | Coating intact; surface resistance change<10%. |

Testing:

Accelerated aging (ASTM F1980) to simulate 10+ years of sterilization cycles.

Post-sterilization performance tests: Capacity retention >90% after 50 autoclave cycles.

2.3 Safety & Reliability Engineering

Leakage Prevention:

Dual-layer encapsulation (e.g., ceramic-coated aluminum + Parylene).

IP68/IP69K-rated sealing for washdown environments (e.g., surgical suites).

Thermal Management:

Phase-change materials (PCMs) or mini heat sinks for implantables.

Thermal runway mitigation: SiO₂-doped separators + voltage/temperature sensors.

SiO₂-doped separators reduce thermal runaway risk by 60% (Data: Nature Energy, 2022).

PCMs (Phase-Change Materials) maintain implantable battery temperatures<40°C.

Battery Management System (BMS):

Medical-grade BMS with redundant safety circuits (ISO 26262 ASIL-C/D).

Real-time monitoring of voltage, current, and impedance for fault detection.

98% of surveyed hospitals reported zero battery failures in ICU devices using medical-grade BMS (2024 MedTech Survey).

2.4 Chemical Compatibility in Medical Environments

Chemical compatibility refers to the ability of materials to resist degradation, corrosion, or adverse reactions when exposed to specific chemicals, solvents, or environments. In the context of hygiene standards lithium battery, chemical compatibility is critical for ensuring, longevity safety and compliance in environments involving disinfectants, bodily fluids, or extreme operating conditions.

Testing Methods & Standards

Test Type | Standard | Procedure | Pass Criteria |

|---|---|---|---|

Immersion Testing | ASTM D543 | Submerge material in chemical (e.g., 75% ethanol) at 70°C for 72 hours. | ≤5% weight change; no cracks/swelling. |

Leachable Analysis | ISO 10993-17 | Use ICP-MS/HPLC to quantify metal ions/organics released into solution. | Ni<0.1 µg/cm²/day; Co <0.05 µg/cm²/day. |

Electrolyte Stability | UL 1642 | Expose battery to electrolyte solvent (e.g., EC/DMC) at 60°C for 7 days. | No leakage; capacity loss<5%. |

VOC Emissions | ASTM E595 | Measure volatile organic compounds (VOCs) under vacuum/heat. | Total mass loss<1%. |

FAQ

1. What are the key hygiene standards lithium battery manufacturers must follow in 2025?

Lithium battery manufacturing hygiene standards prioritize safe production, environmental responsibility, and technological innovation. Large Power's production line meets the ISO Class 7 cleanrooms standard with strict temperature and humidity controls and HEPA/ULPA air filtration systems to prevent contamination.

2. How can you prevent thermal runaway incidents in medical lithium batteries?

Incorporate advanced battery management systems to monitor voltage, temperature, and current. These systems provide protection against overcharging and overheating, reducing thermal runaway incidents effectively.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News