Development of key technologies for silicon negative lithium battery

Jul 08, 2019 Pageview:703

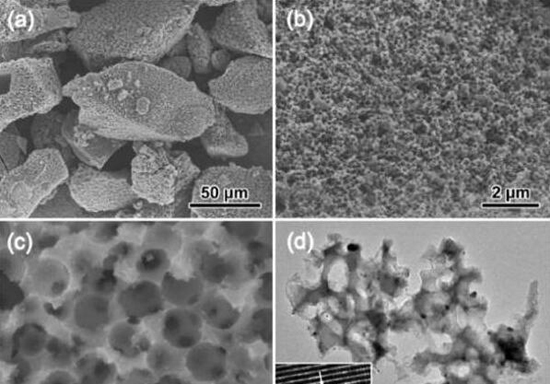

Zheng Xiaoquan, a professor at Xi'an Jiaotong University School of Electrical Engineering, and Cui Wei, a professor at the School of Materials Science at Stanford University, and Li Ju, a professor at the Department of Nuclear Engineering at the Massachusetts Institute of Technology, worked together to coat a surface of a nano-silicon anode with a special method. The titanium dioxide nano-layer is used to synthesize a high-strength Si@TiO2yolk-shell structure anode, and a Si@TiO2 structure silicon anode full battery with high-pressure real density is prepared, which realizes a volume ratio of 2 times that of the conventional graphite anode and 2 Times mass to capacity.

At present, commercial lithium-ion batteries are only used for low-order power requirements, and silicon is expected to be a large-capacity anode material for next-generation lithium-ion batteries because its theoretical specific capacity is more than 10 times that of conventional graphite anodes. However, the problem of low coulombic efficiency of the silicon negative electrode during charge and discharge has not been overcome.

After experimental testing, the new result of the titanium dioxide shell mechanical strength is five times that of amorphous carbon, can achieve a stable Coulomb efficiency of more than 99.9%, to meet the industrial application standards, will effectively promote the commercial bulk of silicon in the battery industry application. The results have been published in the Energy and Environmental Sciences.

The page contains the contents of the machine translation.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News