-

Charging voltage:

-

Automatic recharge:

-

Understanding the Battery Charger Circuit

-

Charging Lithium Ion Batteries with CC and CV

-

Designing the Charger Circuit for a 7.4V Lithium Battery Pack

-

Implementing the Charger Circuit with ANT2801

-

Enhance Your Engineering Capacity with Large Power

-

Frequently Asked Questions (FAQ)+

- How do you charge a 7.4V lithium-ion battery?

- Can I charge a 7.4V battery with a 12V charger?

- What are the three wires on a lithium-ion battery?

- How to make a 7.4V battery pack?

- What ICs can be used for simple battery charger circuits for any chemistry?

- How does the ANT2801 improve the charging process?

7.4V Li-Ion Battery Charger Circuit Diagram: Designing with ANT2801

APR 18, 2025 Pageview:1142

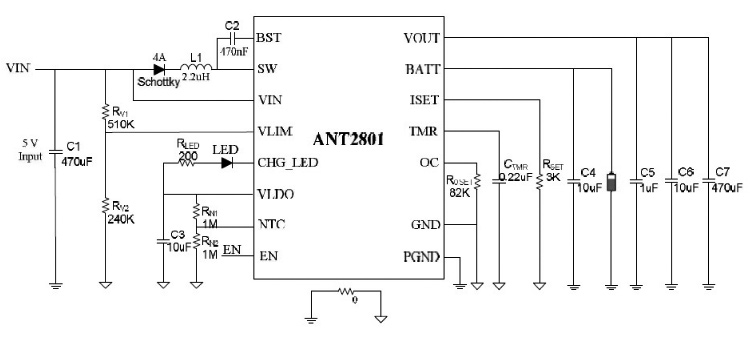

ANT2801 is a wide range of input voltage, specifically for double festival lithium battery charging chip without traditional 9 v adapter for special purpose, just standard 5 v adapter. Charging current can be set by the external resistance chip, through external capacitance charging to set the timeout. The power of the low impedance path can make the charging efficiency is higher, reduce charging time and improve the battery service life. ANT2801 can adaptive adapter's current supply ability to automatically adjust the charging current, ensuring the input adapter will not appear overload phenomenon, and can display adapter maximum current ability. This makes it suitable for all kinds of DC equipment and standard USB charging equipment. With advancements in portable electronics, it is crucial to charge lithium ion batteries carefully to avoid safety concerns. The ANT2801 is designed to address these issues, making it significant for robotics and mobile devices.

ANT2801 adaptive 5 v charger or USB interface 5 v function. That is less than 100 ma / 5 v charging equipment through ANT2801 can give two lithium electricity 7.4 V normal charging series; Greater than 2 a / 5 v charging device can automatically through ANT2801 improve charging current, charging time. The diagram below 5 V charger current (Input current) with two li-ion battery series 7.4 V charging current (Charge Current) relationship (typical):

ANT2801 internal charging management part adopts a set of complete and reliable charging mechanism. Whether the battery connection can work normally without external compensation to realize the stability of the chip. In the process of electricity, first of all, VIN for VOUT charging, when reach the VIN, SW started working shocks, realize booster function, when VOUT, began to detect VBATT condition.

VBATT < 6 v, a trickle charging phase to begin.

6 VBATT 8.4 V or less, or less constant current charging phase to begin.

In the process of charging, CHG_LEDpin between VLDO leds will be kept normally on, after charging, the LED will go out. Charging timeout, LED flashing of fixed frequency state, charging timeout refers to for a long time due to fault charging can't charge, after reaching set the time, LED flashing alarm.

Charging voltage:

if the VBATT > 6.8 V, VOUT will higher than VBATT 300 mv, the purpose is to set the decrease of the maximum charging tube during the period of rapid charging power consumption, improve the charging efficiency.

if the VBATT < 6.8 V, VOUT is fixed at 7.1 V, recharge batteries provide driving ability.

Automatic recharge:

After a charge cycle, ANT2801 will display close the charging state, in the meantime, the battery may be because natural discharge capacity decline, in order to ensure that the battery will not because the connection adapters, power automatically run out, when the battery voltage drops to automatic charging threshold (typically 8.23 V), a new charge cycle will begin automatically.

Understanding the Battery Charger Circuit

A battery charger circuit is an essential component in any electronic device that uses rechargeable batteries. Its primary function is to supply the necessary voltage and current to charge the battery safely and efficiently. For lithium-ion batteries, a two-stage battery charger circuit is commonly employed. This type of charger consists of a constant current (CC) stage and a constant voltage (CV) stage. During the CC stage, the battery is charged at a constant current, which helps to quickly replenish the battery's capacity. Once the battery reaches a certain voltage, the charger transitions to the CV stage, maintaining a constant voltage to prevent overcharging and ensure the battery is fully charged without damage. This two-stage approach is crucial for the longevity and performance of lithium-ion batteries.

Charging lithium ion batteries with CC and CV

Charging lithium-ion batteries requires a careful balance between voltage and current to ensure safety and efficiency. The process begins with the constant current (CC) stage, where the battery is charged at a steady current, typically ranging from 0.5C to 1C (where C represents the battery's capacity). This stage allows for rapid charging. As the battery voltage approaches its maximum threshold, the charger switches to the constant voltage (CV) stage. In this stage, the voltage is held constant, usually at 4.2V for lithium-ion batteries, while the current gradually decreases. This method ensures the battery is topped off without the risk of overcharging, which can lead to reduced battery life or potential safety hazards.

Designing the Charger Circuit for a 7.4v lithium battery Pack

Designing a charger circuit for a 7.4V lithium battery pack involves several key considerations to ensure optimal performance and safety. The charger circuit must provide a constant current of 0.5C to 1C during the CC stage and a constant voltage of 8.4V during the CV stage. To accurately monitor the battery voltage and current, the circuit should include a voltage divider and a shunt resistor. These components help in maintaining precise control over the charging process. Additionally, the design should be flexible enough to accommodate slightly higher battery packs if needed. This adaptability ensures that the charger can be easily modified for different battery configurations, making it a versatile solution for various applications.

Implementing the Charger Circuit with ANT2801

The ANT2801 is a highly efficient IC designed for use in battery charger circuits, particularly for lithium-ion batteries. This IC simplifies the design process by incorporating both the constant current (CC) and constant voltage (CV) stages within a single chip. The ANT2801 also includes a voltage divider and a shunt resistor, which facilitate accurate monitoring of the battery voltage and current. To implement the charger circuit with the ANT2801, connect the IC to the battery and the power supply. Ensure that the voltage divider and shunt resistor are properly connected to the IC to enable precise control over the charging process. This setup not only streamlines the design but also enhances the reliability and efficiency of the charger circuit, making it an ideal choice for charging 7.4V lithium battery packs.

Enhance Your Engineering Capacity with Large Power

Large Power, with over 23 years of expertise in custom battery pack solutions, is your go-to partner for enhancing your engineering capabilities. Whether you're designing a 7.4V lithium-ion battery charger circuit or exploring advanced battery technologies, Large Power offers tailored solutions to meet your specific needs. Their extensive experience in battery pack design and manufacturing ensures that you receive high-quality, reliable products that boost your project's performance. Partner with Large Power to leverage their knowledge and resources, and take your engineering projects to the next level.

Contact us for any battery charger circuit and pack design inquiry!

Frequently Asked Questions (FAQ)

How do you charge a 7.4V lithium-ion battery?

To charge a 7.4V lithium-ion battery, you need a charger circuit that provides a constant current (CC) and a constant voltage (CV). The CC stage charges the battery at a steady current, while the CV stage maintains a constant voltage to prevent overcharging. The ANT2801 IC is an excellent choice for this purpose as it integrates both charging stages and ensures safe and efficient charging.

Can I charge a 7.4V battery with a 12V charger?

Charging a 7.4V battery directly with a 12V charger is not recommended as it can lead to overcharging and damage the battery. Instead, use a charger circuit specifically designed for 7.4V lithium-ion batteries, which regulates the voltage and current appropriately.

What are the three wires on a lithium-ion battery?

The three wires on a lithium-ion battery typically include a positive wire, a negative wire, and a third wire for temperature monitoring or balancing. The third wire helps ensure safe charging by monitoring the battery's temperature or balancing the charge across multiple cells in a battery pack.

How to make a 7.4V battery pack?

To make a 7.4V battery pack, connect two 3.7V lithium-ion cells in series. This configuration doubles the voltage to 7.4V while maintaining the same capacity. Ensure that the cells are balanced and use a battery management system (BMS) to monitor and protect the pack during charging and discharging.

What ICs can be used for simple battery charger circuits for any chemistry?

For simple battery charger circuits, ICs like the LM317 voltage regulator can be used for various battery chemistries. It provides a straightforward solution for regulating output voltage and current, making it suitable for different types of batteries.

How does the ANT2801 improve the charging process?

The ANT2801 improves the charging process by incorporating both constant current (CC) and constant voltage (CV) stages in a single chip. It automatically adjusts the charging current based on the adapter's supply capability, ensuring efficient charging without overloading the power source. The ANT2801 also includes features for monitoring battery voltage and current, enhancing the safety and reliability of the charging process.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News