-

Key Takeaways

-

Part 1: Identifying Power Requirements+

- 1.1 Calculating Energy Needs for Different Battery Sizes

- 1.2 Determining Voltage and Current for the Best Battery Size

- 1.3 Estimating Runtime and Load Demands for Choosing the Right Battery Size

-

Part 2: Understanding Battery Capacity and Voltage+

- 2.1 Defining Battery Capacity: Ah vs. Wh

- 2.2 Calculating Usable Capacity for the Correct Type and Size

- 2.3 Matching Voltage to System Requirements

-

Part 3: Evaluating Battery Chemistry and Types+

- 3.1 Overview of Lithium Battery Chemistries (LiFePO4, NCM, LCO, etc.)

- 3.2 Pros and Cons of Different Battery Sizes and Chemistries

- 3.3 Selecting the Correct Type and Size for Your Application

-

Part 4: Cost vs. Value Analysis+

- 4.1 Balancing Upfront Costs with Long-Term Value

- 4.2 Total Cost of Ownership (TCO) for Lithium Battery Packs

- 4.3 Maximizing ROI with the Best Battery Size

-

FAQ+

- 1. What factors determine the lifespan of lithium-ion batteries?

- 2. How do you identify the application for the correct lithium battery type?

- 3. Why are lithium-ion batteries preferred for industrial applications?

What to Consider When Selecting Lithium Battery Sizes for Your System

APR 21, 2025 Pageview:17

Choosing the right battery size, including different battery sizes, is critical for optimizing your industrial and commercial systems. Proper battery selection ensures operational efficiency, safety, and cost-effectiveness. For example, a 600kW 4-hour battery system can achieve capital expenditure reductions of up to 52% in advanced scenarios, with annual savings rates of 4.0%. Lithium battery packs play a pivotal role in industries like medical, robotics, infrastructure, and energy storage, supporting both performance and reliability in demanding environments.

Key Takeaways

Figure out how much energy your system needs. Use this formula: Battery Capacity (kWh) = (Daily Energy Use ÷ Efficiency) ÷ DoD.

Pick the right battery type for your needs. LiFePO4 batteries are strong and safe. NCM batteries store more energy in less space.

Think about cost now and savings later when choosing a battery. Look at things like how long it lasts, maintenance costs, and energy savings to get the best value.

Part 1: Identifying Power Requirements

1.1 Calculating Energy Needs for Different Battery Sizes

Understanding your system's energy needs is the first step in choosing the right battery. To calculate the size of the battery required, you must evaluate daily energy consumption, efficiency, and depth of discharge (DoD). Use the formula:

Battery Capacity (kWh) = (Daily Energy Consumption ÷ Efficiency) ÷ DoD

For example, if your system consumes 10 kWh daily, operates at 90% efficiency, and has a DoD of 80%, the required capacity would be approximately 13.89 kWh. This calculation ensures that the battery can meet your power needs without compromising performance. Accurate energy calculations are particularly critical in industries like medical and robotics, where reliability is paramount.

1.2 Determining Voltage and Current for the Best Battery Size

Voltage and current parameters play a vital role in selecting the best battery size for your system. The Battery Management System (BMS) must provide precise data despite challenging conditions like high voltage/current inverters and temperature fluctuations.

Robust design begins with comprehensive monitoring of individual battery cells. Cell readings require millivolt and milliamp accuracy, and voltage and current measurements must be time-synchronized to calculate power effectively.

To determine charger current, use the following formula:

Step | Description | Formula |

|---|---|---|

1 | Determine Recharge Factor (RF) | RF = 1.40 (assumed) |

2 | Determine Altitude Derating (AD) | AD = 1 (no derating) |

3 | Calculate Charger Current (C) | C = (((AH × RF) / RT) + CL) × DM × AD |

Where:

AH = Battery Amp Hours

RF = Recharge Efficiency Factor

RT = Required Recharge Time (in hours)

CL = Continuous Load (in amps)

DM = Design Margin (as a decimal)

AD = Altitude Derating Factor

These calculations ensure that your battery meets the required capacity for your application, whether in infrastructure or industrial systems.

1.3 Estimating Runtime and Load Demands for Choosing the Right Battery Size

Runtime estimation is essential for matching battery size to load demands. Begin by calculating the energy storage required in kWh-per-day based on your system's load. Multiply the wattage of each load by its runtime to determine the minimum kWh-per-day.

Example: For a load consuming 10 kWh daily and requiring 1.5 days of backup power, the storage capacity needed is 15 kWh.

This calculation helps determine the number of batteries required based on their capacity.

Industries like energy storage rely heavily on accurate runtime estimations to ensure uninterrupted operations. Following IEEE standards such as IEEE 1115 and IEEE 485 can provide valuable recommendations for battery sizing tailored to specific applications.

For customized solutions, explore Large Power consultation services to optimize your battery system.

Part 2: Understanding Battery Capacity and Voltage

2.1 Defining Battery Capacity: Ah vs. Wh

Battery capacity is a critical factor in determining the performance and efficiency of your system. It is typically measured in ampere-hours (Ah) or watt-hours (Wh). While Ah indicates the amount of current a battery can deliver over time, Wh provides a more comprehensive measure by factoring in voltage. For example:

Battery Type | Ah Rating | Wh Rating | Comparison |

|---|---|---|---|

18V 5Ah | 5 | 90 | 90 Wh is 25% greater than 72 Wh |

20V Max 5Ah | 5 | 100 | 100 Wh is 25% greater than 80 Wh |

Understanding this distinction helps you select the correct type and size of battery for your application. Wh ratings are particularly useful for systems requiring precise energy calculations, such as medical devices or robotics.

2.2 Calculating Usable Capacity for the Correct Type and Size

Usable capacity refers to the energy a battery can deliver under real-world conditions. This value depends on factors like depth of discharge (DoD), efficiency, and battery chemistry. Common methods for determining usable capacity include:

Method Type | Description |

|---|---|

Direct Measurement | Uses a tester to discharge the battery and record energy until cutoff. |

Indirect Measurement | Estimates capacity by observing discharge rates and calculating total discharge time. |

Voltage Estimation | Provides a rough estimate based on predictable voltage behavior of lithium-ion batteries. |

For instance, a LiFePO4 Lithium battery with a DoD of 80% and a nominal capacity of 100Ah will have a usable capacity of 80Ah. Accurate calculations ensure your system operates efficiently and safely, especially in industrial or infrastructure applications.

2.3 Matching Voltage to System Requirements

Matching battery voltage to your system's requirements is essential for optimal performance and safety. Voltage indicates the state-of-charge in an open circuit condition, while internal resistance affects current delivery. Misalignment can lead to reduced efficiency or even system failure. Key considerations include:

Voltage and current capacity alignment ensures accurate testing and realistic simulation of device behavior.

Battery management systems (BMS) monitor voltage and capacity to maintain safety and extend lifespan.

For example, a 48V system requires a battery pack with a matching voltage output to avoid overloading or underpowering the system. This alignment is crucial in energy storage and industrial applications where reliability is non-negotiable.

For tailored solutions, explore our consultation services to optimize your battery system.

Part 3: Evaluating Battery Chemistry and Types

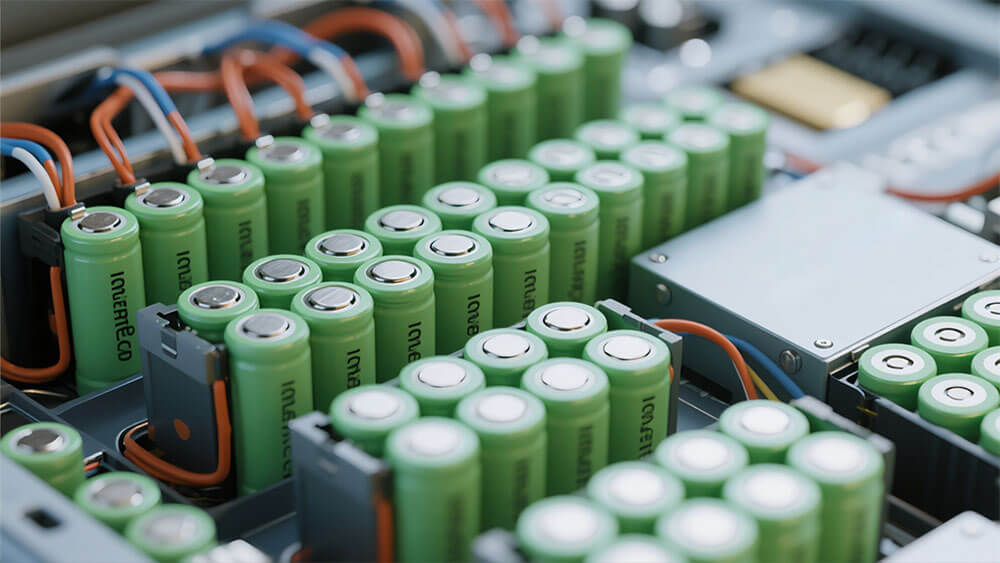

3.1 Overview of Lithium Battery Chemistries (LiFePO4, NCM, LCO, etc.)

Lithium-ion batteries come in various chemistries, each tailored to specific applications. Common types include LiFePO4, NCM, and LCO. LiFePO4 Lithium batteries are renowned for their safety features, long cycle life, and thermal stability, making them ideal for industrial and infrastructure applications. NCM Lithium batteries, with their high energy density and moderate cycle life, are widely used in energy storage and electric vehicles. LCO Lithium batteries dominate consumer electronics due to their compact size and high energy density.

Recent advancements in lithium battery chemistries have introduced silicon and lithium-metal anodes, enhancing energy density by 30-40%. High-nickel NMC cathodes and solid-state technologies are also under development, promising improved performance and safety. These innovations are pivotal for industries like medical and robotics, where reliability is critical.

3.2 Pros and Cons of Different Battery Sizes and Chemistries

Understanding the strengths and limitations of each lithium-ion chemistry helps you make informed decisions. The table below summarizes key performance metrics:

Lithium Chemistry | Nominal Voltage (V) | Specific Energy (Wh/kg) | Cycle Life | Thermal Runaway (°C) | Comments |

|---|---|---|---|---|---|

LiFePO4 | 3.20 | 100–180 | 2,000+ | 270 | Safe, long life, moderate energy |

NCM | 3.5–3.6 | 160–270 | 1,000–2,000 | N/A | High energy density, moderate cycle life |

LCO | 3.7 | 180–230 | 500–1,000 | N/A | High energy density, less safe |

LiFePO4 batteries excel in safety and durability, while NCM batteries offer higher energy density but require robust thermal management. LCO batteries, though compact, pose safety challenges due to their susceptibility to thermal runaway.

3.3 Selecting the Correct Type and Size for Your Application

Choosing the right lithium-ion battery depends on your system's requirements. For applications demanding high battery capacity and safety features, such as industrial systems, LiFePO4 Lithium batteries are a reliable choice. NCM Lithium batteries suit energy storage systems where energy density is a priority. LCO Lithium batteries are optimal for compact devices in consumer electronics.

Evaluate factors like voltage compatibility, cycle life, and thermal stability to ensure the battery aligns with your operational needs. Consulting professionals can help you design a customized solution tailored to your application. Explore Large Power consultation services for expert guidance.

Part 4: Cost vs. Value Analysis

4.1 Balancing Upfront Costs with Long-Term Value

When selecting a battery for your system, balancing upfront costs with long-term value is essential. While lithium batteries may have a higher initial cost compared to alternatives like lead-acid batteries, their long-term benefits often outweigh the investment. For instance:

Economies of Scale: Purchasing batteries in bulk reduces per-unit costs, leading to significant savings over time.

Less Frequent Replacement: Lithium batteries, such as LiFePO4 Lithium batteries, offer longer lifespans, minimizing replacement expenses.

Energy Savings: Battery Energy Storage Systems (BESS) can lower energy costs by optimizing usage and reducing reliance on grid power.

Although the upfront cost of BESS may seem high, the long-term advantages—such as energy independence and reduced carbon footprints—make them a cost-effective choice for industries like infrastructure and energy storage.

4.2 Total Cost of Ownership (TCO) for lithium battery packs

The Total Cost of Ownership (TCO) provides a comprehensive view of the financial implications of selecting a battery. Over a 10-year period, lithium batteries outperform lead-acid batteries and internal combustion engine (ICE) systems in several key areas:

Lower Maintenance Costs: Lithium batteries require less upkeep due to their advanced design and fewer replacements.

Higher Energy Efficiency: Lithium batteries operate at 80% efficiency, compared to 30% for ICE systems, reducing operational costs.

Extended Lifespan: With over 3,500 cycles, lithium batteries last significantly longer than lead-acid batteries, which average 1,000 cycles.

These factors make lithium batteries a superior choice for applications requiring reliability and cost efficiency, such as industrial systems and medical devices.

4.3 Maximizing ROI with the Best Battery Size

Maximizing your return on investment (ROI) involves selecting a battery size that aligns with your system's needs. Key strategies include:

Duration Optimization: A 2-cycle, 2-hour-duration battery maximizes revenue opportunities.

Degradation Management: Maintaining optimal state-of-charge (SOC) ranges preserves battery health and extends lifespan.

Flexibility: Batteries with higher charge acceptance rates reduce energy losses and allow for frequent recharges without degradation.

Factor | Description |

|---|---|

Duration | A 2-cycle 2-hour-duration asset maximizes revenue opportunities. |

Degradation | Managing degradation through optimal SOC ranges retains battery capacity and enhances ROI. |

Flexibility | 2-hour batteries provide flexibility in revenue streams and optimization strategies. |

Health Maintenance | Keeping the battery healthy through strategic trading limits degradation and optimizes SoH. |

By carefully selecting a battery size that meets your operational demands, you can achieve higher efficiency and profitability. For tailored solutions, explore Large Power consultation services to optimize your battery system.

Selecting the right lithium battery size involves understanding critical factors like power requirements, total battery capacity, voltage, and chemistry. These elements ensure your system operates efficiently and safely. For example:

Battery capacity impacts runtime and performance.

Voltage compatibility ensures seamless integration with devices.

Chemistry determines safety and efficiency.

Consulting professionals helps you design a lithium-ion battery solution tailored to your needs. This approach minimizes risks and maximizes long-term value. Explore Large Power consultation services to optimize your system with customized lithium-ion battery packs.

FAQ

1. What factors determine the lifespan of lithium-ion batteries?

The lifespan depends on charge cycles, operating temperature, and discharge depth. Proper maintenance and avoiding over-discharge can extend battery life.

2. How do you identify the application for the correct lithium battery type?

Evaluate energy requirements, voltage compatibility, and environmental conditions. For example, medical devices demand high reliability and safety standards.

3. Why are lithium-ion batteries preferred for industrial applications?

They offer high energy density, long cycle life, and efficient discharge rates, making them ideal for demanding industrial systems. Explore Large Power customized solutions for your needs.

- Prev Article: NCM Lithium Batteries and Their Superior Performance Characteristics

- Next Article: Are Lithium Batteries Safe When Exposed to Water

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News