-

Key Takeaways

-

Part 1: Chemistry of NCM Batteries+

- 1.1 Composition and Structure of NCM Battery Cathodes

- 1.2 Role of Nickel, Cobalt, and Manganese in Battery Performance

- 1.3 Impact of Cathode Chemistry on Energy Density and Stability

-

Part 2: NCM Battery vs. Other Battery Types+

- 2.1 NCM vs. LiFePO4: Energy Density and Cost Comparison

- 2.2 NCM vs. LCO: Performance, Safety, and Applications

- 2.3 Weight and Endurance: Advantages of NCM Batteries

-

Part 3: Challenges and Degradation Mechanisms in NCM Batteries+

- 3.1 Common Degradation Mechanisms in NCM Chemistry

- 3.2 Thermal Stability and Safety Concerns in NCM Batteries

- 3.3 Strategies to Mitigate Degradation and Improve Longevity

-

Part 4: Advancements in NCM Battery Technology+

- 4.1 Development of Ni-Rich NCM Variants for Enhanced Performance

- 4.2 Innovations in Cathode Design to Boost Efficiency

- 4.3 Future Applications of NCM Batteries in Consumer Electronics

-

FAQ+

- 1. What makes NCM batteries stand out in energy storage?

- 2. How does the composition of NCM batteries enhance performance?

NCM Lithium Batteries and Their Superior Performance Characteristics

APR 21, 2025 Pageview:17

NCM batteries signify a major advancement in lithium-ion battery technology, delivering exceptional energy density and an extended cycle life. These features establish them as a leading option for energy storage solutions. NCM batteries are widely utilized in consumer electronics, with their market value expected to rise from $3 billion in 2024 to $8.5 billion by 2035, fueled by the growing demand for portable devices. Furthermore, their dependability and efficiency have made them a favored choice for renewable energy systems, contributing to the worldwide transition toward carbon reduction.

Key Takeaways

NCM batteries store a lot of energy, between 160 to 270 Wh/kg. This makes them great for small designs and long-lasting use.

The mix of nickel, cobalt, and manganese in NCM batteries improves their strength and performance. They can last up to 2,000 cycles.

New ideas in NCM technology, like nickel-rich types and better cathodes, will make them work even better and more reliably in the future.

Part 1: Chemistry of NCM Batteries

1.1 Composition and Structure of NCM Battery Cathodes

The cathodes in NCM batteries consist of nickel, cobalt, and manganese, forming a layered structure that optimizes energy storage and stability. Nickel enhances the energy density, allowing NCM batteries to achieve specific capacities ranging from 160 to 270 Wh/kg. Cobalt contributes to structural integrity, ensuring consistent performance during charge-discharge cycles. Manganese balances the composition, improving thermal stability and reducing degradation risks.

Recent studies have explored the structural composition of NCM cathodes, revealing key insights into their performance. For example:

Study Focus | Key Findings | Statistical Methods Used |

|---|---|---|

Identified pathways vary with nickel content | Statistical analysis of empirical studies | |

Mitigation strategies for NCM ageing | Tailoring electrode formulation and microstructure | Evidence-based approach to optimization |

Impact of doping on structural stability | Doping mitigates lattice expansion | Statistical correlation with performance metrics |

These findings highlight the importance of cathode materials in achieving high energy density and long cycle life, making NCM batteries a preferred choice for energy storage systems.

1.2 Role of Nickel, Cobalt, and Manganese in Battery Performance

Nickel, cobalt, and manganese each play distinct roles in enhancing the performance of NCM batteries. Nickel increases the energy storage capacity, enabling higher energy density. Cobalt stabilizes the layered structure, ensuring reliable operation under varying conditions. Manganese contributes to overall stability, reducing the risk of thermal runaway.

Numerical comparisons further illustrate their contributions:

Component | Contribution to Performance | Notes |

|---|---|---|

Nickel | NCM-811 has a high nickel content, enhancing energy capacity | |

Cobalt | Stability issues | Cobalt helps with stability but is less emphasized in high nickel compositions |

Manganese | Balances stability | Manganese contributes to overall stability in NCM compositions |

By leveraging these materials, NCM batteries achieve superior energy density and reliability, making them ideal for applications in lithium-ion batteries used in consumer electronics and renewable energy systems.

1.3 Impact of Cathode Chemistry on Energy Density and Stability

The chemistry of NCM cathodes directly influences the energy density and stability of lithium-ion batteries. Nickel-rich variants, such as NCM-811, offer higher energy density, supporting applications that demand extended runtime and compact designs. However, balancing nickel with cobalt and manganese ensures structural stability and mitigates degradation mechanisms.

Part 2: NCM Battery vs. Other Battery Types

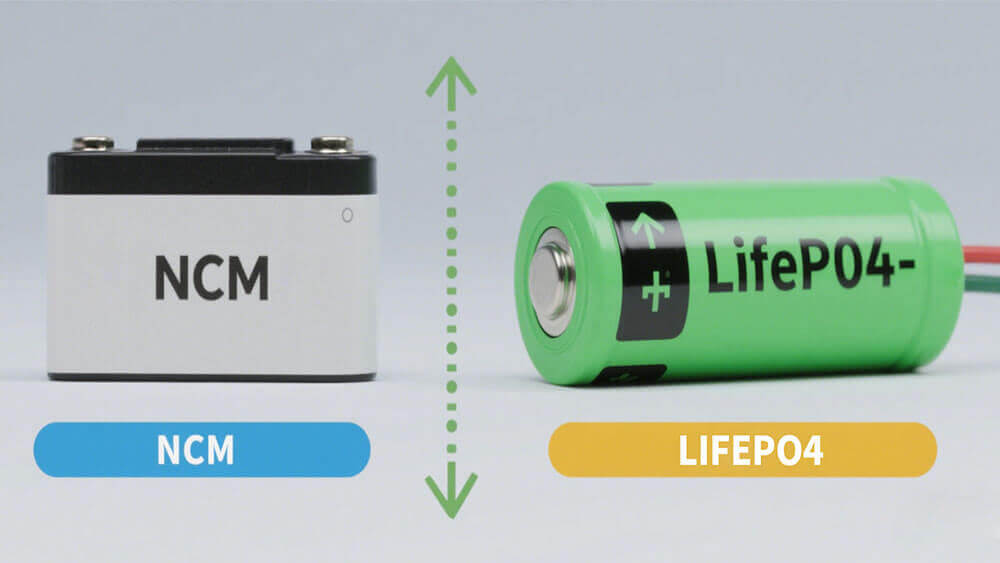

2.1 NCM vs. LiFePO4: Energy Density and Cost Comparison

When comparing NCM batteries to LiFePO4 batteries, energy density and cost emerge as critical factors. NCM batteries offer an energy density ranging from 160 to 270 Wh/kg, significantly higher than the 100 to 180 Wh/kg range of LiFeO4 batteries. This makes NCM batteries ideal for applications requiring compact designs and extended runtimes, such as electric vehicles and high-performance energy storage systems.

Battery Type | Energy Density (Wh/kg) |

|---|---|

LiFePO4 | 100 to 180 |

NCM | 160 to 270 |

In terms of cost, NCM batteries benefit from supply chain advantages, resulting in lower initial capital costs. While LiFeO4 batteries may offer better long-term financial viability due to their extended cycle life, the higher energy density of NCM batteries often justifies their upfront investment for businesses prioritizing performance and space efficiency.

Battery Type | Energy Density | Cost Comparison |

|---|---|---|

NCM | Higher | Lower capital cost due to supply chain advantages |

LiFeO4 | High | Better long-term financial viability due to longer cycle life |

2.2 NCM vs. LCO: Performance, Safety, and Applications

NCM batteries outperform LCO batteries in several key areas. While LCO batteries provide an energy density of 180 to 230 Wh/kg, NCM batteries achieve a comparable range of 160 to 270 Wh/kg. However, NCM batteries offer a longer cycle life, typically ranging from 1,000 to 2,000 cycles, compared to the 500 to 1,000 cycles of LCO batteries. This makes NCM batteries more suitable for applications requiring durability, such as renewable energy storage and industrial battery packs.

Safety is another area where NCM batteries excel. The inclusion of manganese in their composition enhances thermal stability, reducing the risk of overheating. This makes them a safer choice for large-scale energy storage systems. Additionally, their versatility allows them to be used in a wide range of applications, from consumer electronics to electric vehicles.

2.3 Weight and Endurance: Advantages of NCM Batteries

NCM batteries strike an excellent balance between weight and endurance. Their high energy density enables the production of lightweight battery packs without compromising on capacity. This is particularly advantageous for industries like automotive and aerospace, where reducing weight is critical for improving efficiency and performance.

Moreover, the endurance of NCM batteries, with a cycle life of up to 2,000 cycles, ensures long-term reliability. This makes them a preferred choice for businesses seeking robust and efficient energy storage solutions. Whether you are designing battery packs for renewable energy systems or high-performance consumer electronics, NCM batteries deliver unmatched value.

Part 3: Challenges and Degradation Mechanisms in NCM Batteries

3.1 Common Degradation Mechanisms in NCM Chemistry

NCM batteries, like all lithium-ion batteries, face degradation over time due to chemical and structural changes in their materials. One of the primary challenges involves the cathodes. Repeated charge-discharge cycles can lead to structural instability in the cathode materials, particularly in NCM compositions with high nickel content. This instability reduces capacity retention and impacts the electrochemical performance of the battery.

Another common issue is the growth of dendrites on the lithium-negative electrodes. These needle-like structures can puncture the separator, increasing the risk of short circuits. Additionally, the high energy density of NCM batteries can accelerate side reactions, further contributing to capacity loss. Addressing these degradation mechanisms is crucial for maintaining the cycle life and reliability of NCM batteries in energy storage systems.

3.2 Thermal Stability and Safety Concerns in NCM Batteries

Thermal stability remains a critical factor in the performance and safety of NCM batteries. While the inclusion of manganese in NCM cathodes enhances stability, high nickel content can increase the risk of thermal runaway under extreme conditions. This makes it essential to monitor and manage the thermal behavior of NCM materials.

To illustrate, NCM batteries retain 96% of their capacity after 160 cycles, showcasing their durability. However, challenges such as separator puncturing and short circuits can compromise safety. These risks highlight the importance of designing battery packs with robust thermal management systems to ensure consistent performance and safety.

3.3 Strategies to Mitigate Degradation and Improve Longevity

You can adopt several mitigation strategies from Large Power to enhance the longevity of NCM batteries. Optimizing cathode materials, such as developing ni-rich cathodes, can improve energy density while maintaining structural stability. Advanced coating techniques on cathodes also help reduce side reactions, preserving capacity over extended cycles.

Thermal management systems play a vital role in addressing safety concerns. By incorporating efficient cooling mechanisms, you can prevent overheating and ensure the stable operation of NCM batteries. Additionally, ongoing research into ncm active materials aims to further enhance the electrochemical performance and cycle life of these batteries, making them a reliable choice for energy storage applications.

Part 4: Advancements in NCM Battery Technology

4.1 Development of Ni-Rich NCM Variants for Enhanced Performance

Ni-rich NCM variants represent a significant leap in lithium-ion batteries. These advanced cathodes, such as LiNi0.94Co0.05Te0.01O2, deliver exceptional performance metrics. For instance:

They achieve an initial capacity of 239 mAh/g and retain 94.5% capacity after 200 cycles.

At 55 °C, cycling stability reaches 87%, far surpassing earlier compositions.

With a cut-off charge voltage of 4.4 V, they maintain nearly 99% capacity after 100 cycles at 0.5 C.

These improvements stem from optimized nickel content, which boosts energy density while minimizing voltage decay. By adopting Ni-rich NCM technology, you can achieve higher efficiency and longer-lasting batteries for demanding applications.

4.2 Innovations in Cathode Design to Boost Efficiency

Advancements in cathode design have revolutionized lithium-ion batteries. Researchers now employ advanced coating techniques to reduce side reactions, preserving capacity over extended cycles. Enhanced microstructures also improve ion flow, ensuring consistent performance. For example, NC95T exhibits negligible voltage polarization compared to earlier designs, resulting in superior energy retention.

These innovations directly benefit industries relying on high-performance batteries. Whether you need reliable energy storage for renewable systems or lightweight solutions for electric vehicles, modern cathode designs ensure optimal efficiency.

4.3 Future Applications of NCM Batteries in Consumer Electronics

NCM batteries continue to shape the future of consumer electronics. Their high energy density and long cycle life make them ideal for portable devices like smartphones, laptops, and wearables. As technology evolves, you can expect even more compact and powerful devices powered by NCM batteries.

Emerging trends also point to their integration into smart home systems and IoT devices. These applications demand reliable, long-lasting energy solutions, and NCM batteries deliver unmatched performance. By leveraging advancements in NCM technology, you can stay ahead in a rapidly changing market.

NCM batteries stand out due to their advanced chemistry and exceptional performance. Their specific energy ranges from 160 to 270 Wh/kg, surpassing alternatives like LiFePO4 batteries. With a cycle life of up to 2,000 cycles, they ensure long-term reliability. Future advancements promise even greater efficiency, making NCM the ideal choice for energy storage solutions across industries.

FAQ

1. What makes NCM batteries stand out in energy storage?

NCM batteries offer high energy density, long cycle life, and excellent reliability. These features make them ideal for applications like renewable energy systems and consumer electronics.

2. How does the composition of NCM batteries enhance performance?

The combination of nickel, cobalt, and manganese optimizes energy density, stability, and safety. This unique chemistry ensures consistent performance across various applications. Please contact Large Power according to your needs

- Prev Article: no more

- Next Article: What to Consider When Selecting Lithium Battery Sizes for Your System

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News